Portable fast detector for detecting bonding stress of steel bar

A gripping force, portable technology, applied in the direction of applying stable tension/pressure to test material strength, instruments, measuring devices, etc., can solve the problem of restricting the use of reinforced concrete gripping force testing equipment, testing equipment can not meet the use requirements, Unable to carry out actual detection and other problems, to achieve the effect of reducing weight, avoiding damage to steel bars, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

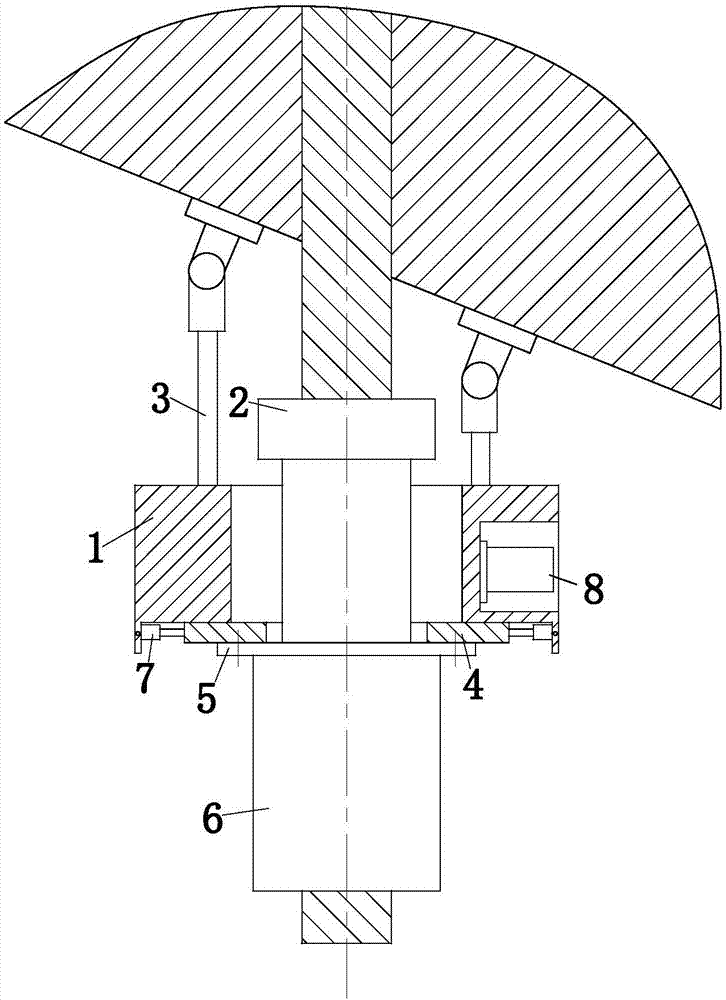

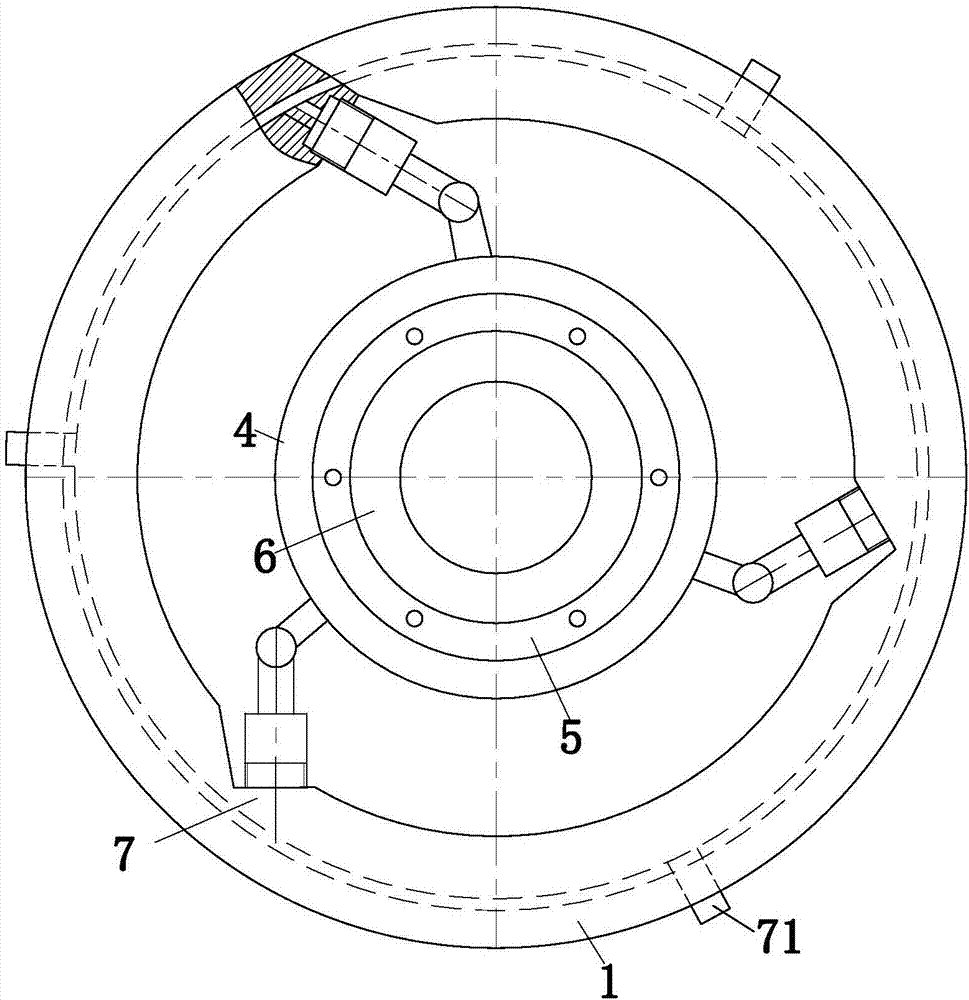

[0021] Such as figure 1 and figure 2 As shown, a portable quick tester for gripping force of steel bars includes a housing 1, a fixture 2, a hydraulic support 3, a movable plate 4, a flange 5, a hollow jack 6, a hydraulic cylinder 7, a micro hydraulic pump 8, a digital display Type pressure gauge, input panel, display and controller, characterized in that: the housing 1 is an annular structure, the housing 1 is provided with an annular oil tank; the clamp 2 is installed on the telescopic rod of the hollow jack 6 and Located above the housing 1, the clamp 2 is used to clamp the steel bar; the hydraulic support 3 is installed on the housing 1, and there are at least three hydraulic supports 3, and the hydraulic supports 3 are connected in series; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com