Minisize air lift pump with low power consumption air guide structure

An air guide structure, low power consumption technology, applied in the direction of pumps, multi-stage pumps, pump components, etc., can solve the problems of twists and turns, large air resistance, increased power consumption, etc., to achieve a simple assembly process, smooth air flow channels , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

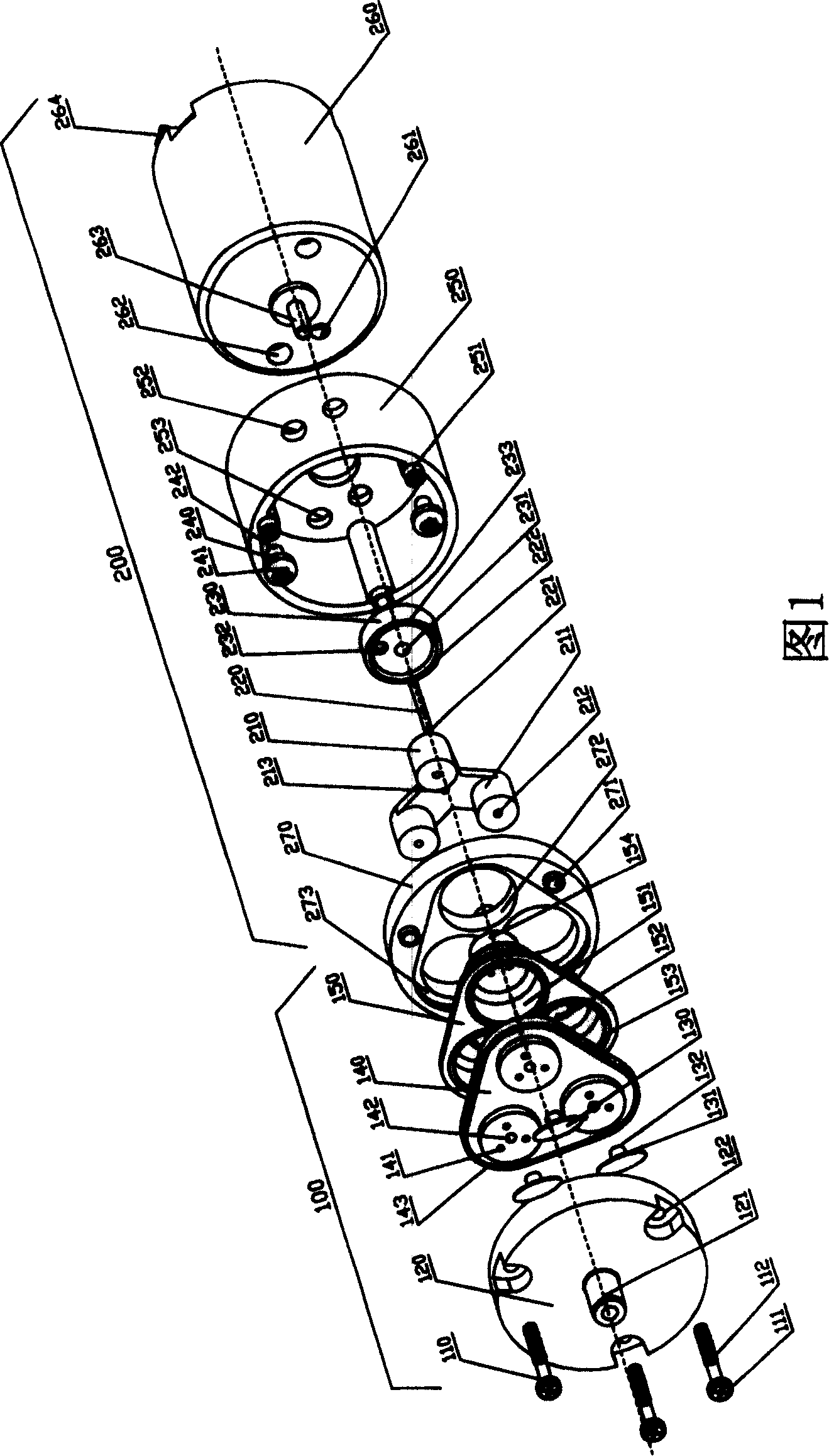

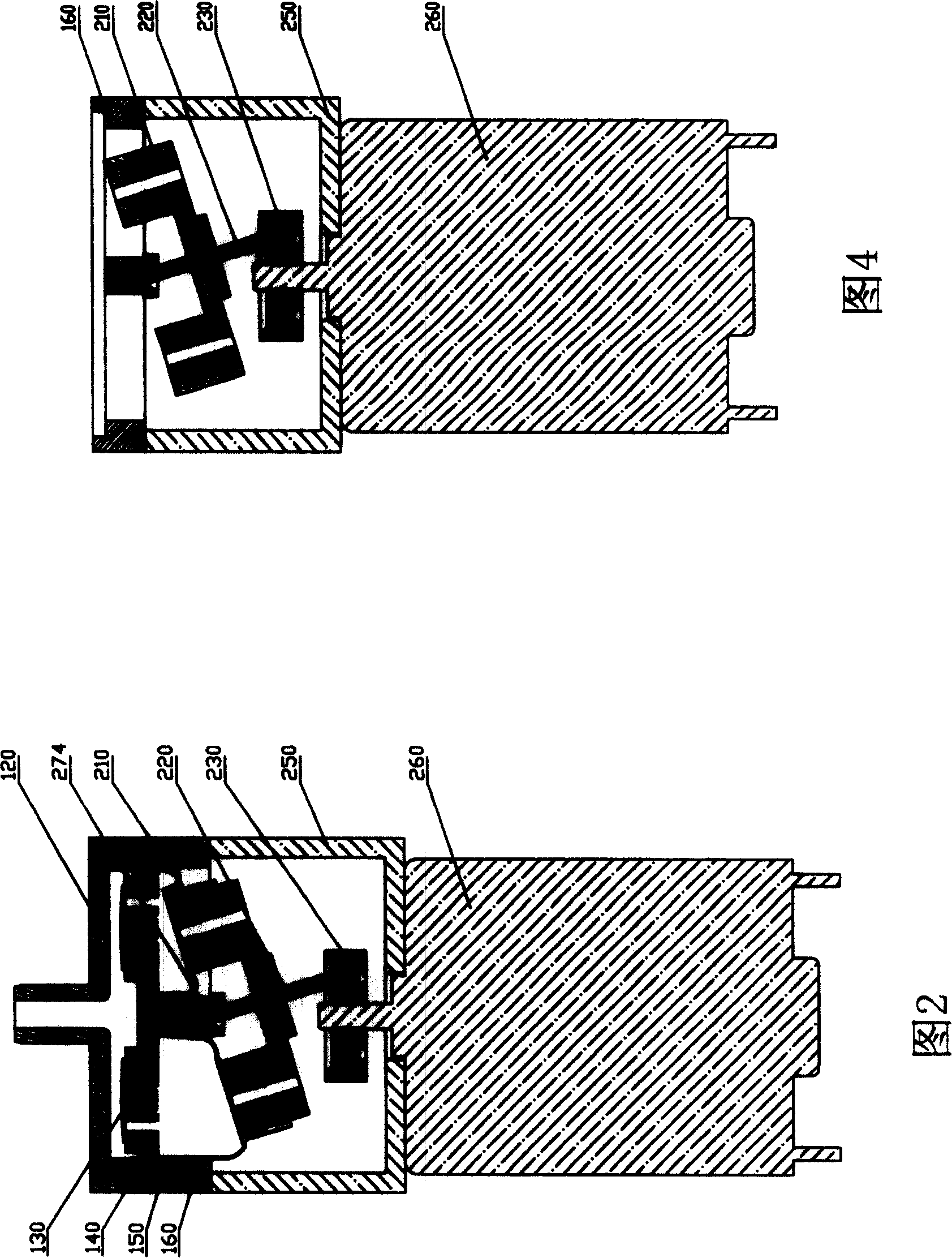

[0032] 1 and 2, the miniature pneumatic pump with a low power consumption air diversion structure of the present invention is composed of a gas diversion assembly 100 and a transmission assembly 200.

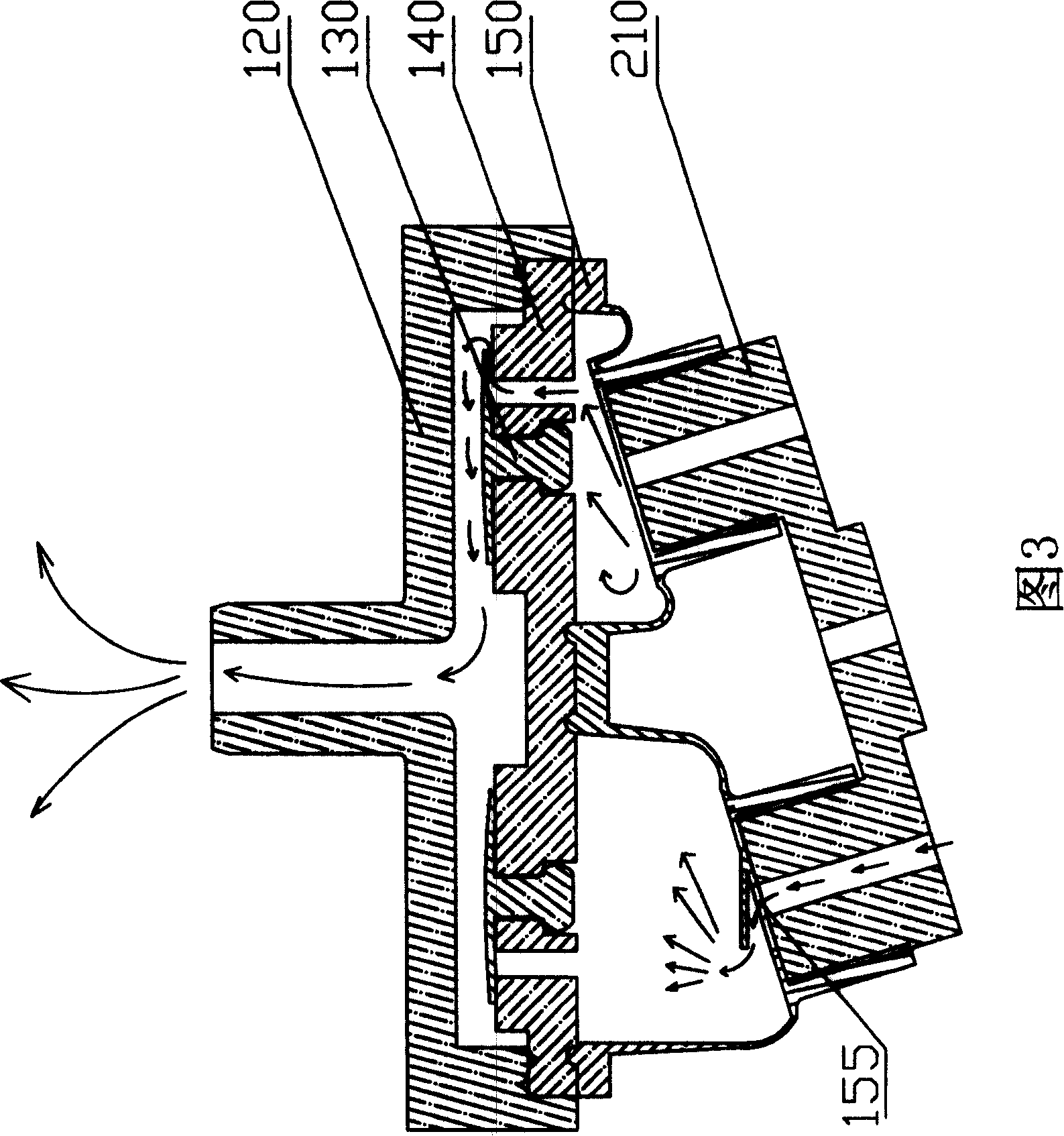

[0033]Please also refer to FIG. 3, the transmission assembly 200 includes a motor 260, a base 250, a motor fixing screw 240, an eccentric wheel, a transmission shaft 220, a compression piece 210, and a piston bracket 270. The motor 260 has an air inlet 261, and the bottom of the motor 260 has a motor terminal 264. The base 250 is provided with an assembly positioning hole 251 and an air inlet 252 for integral assembly. The air inlet 252 and the air inlet 261 are used to guide the piston The cavity 151 is supplied with external air, and the base 250 is fixed on the motor 260 through the cooperation of two motor fixing screws 240 with spring washers 241 and the screw fixing holes 253 on the motor 260. A spherical hole 274 is opened at the center of the rear of the piston bracket 270 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com