Macromolecule intralayer shear orientation measurement method based on interdigital electrode

An interdigital electrode and measurement method technology, applied in the field of polymer orientation measurement, can solve the problems of complex equipment and difficult sample preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

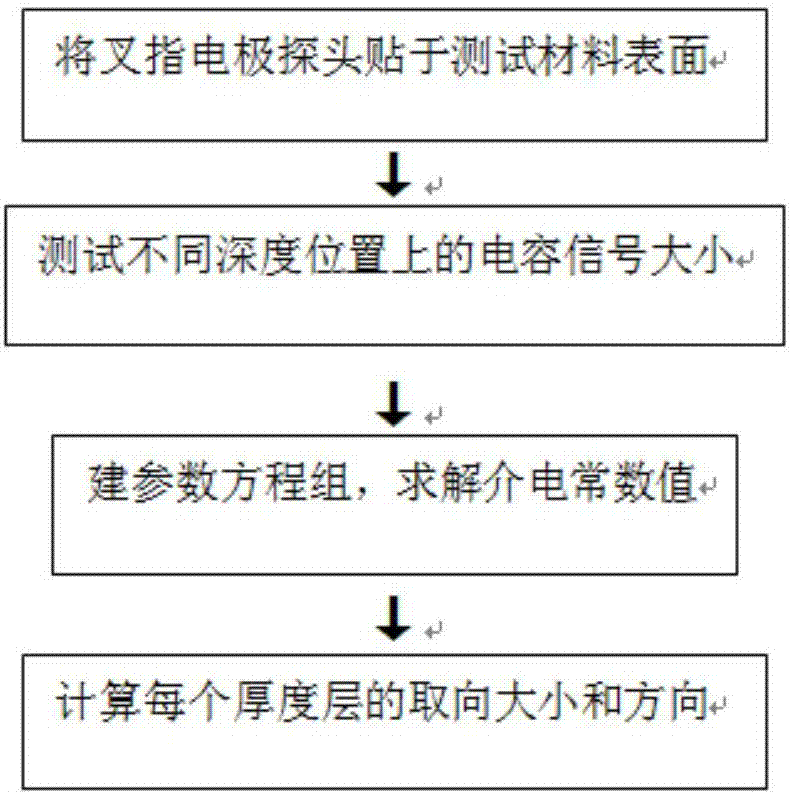

Method used

Image

Examples

Embodiment

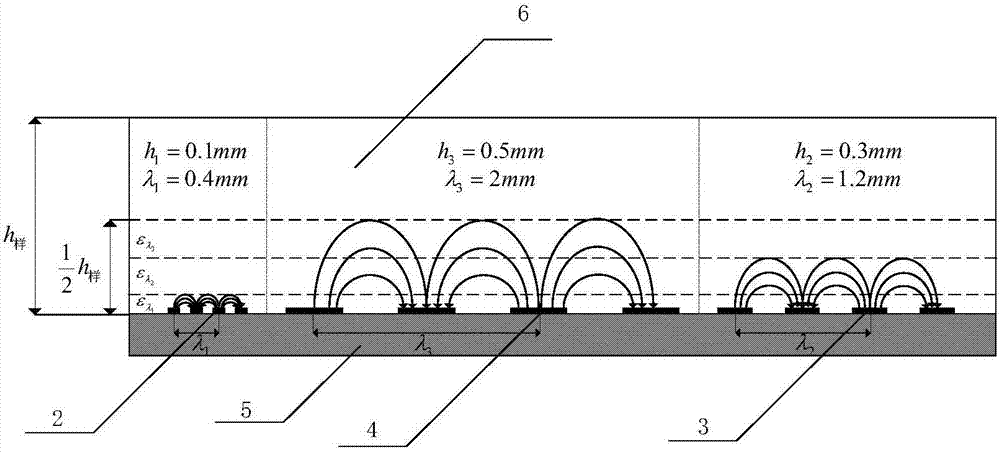

[0064] The injection molding used in this embodiment obtains the polymer material to be tested sample 7 with a thickness of 1 mm. According to the principle of symmetry, only the orientation within 0.5 mm thickness can be measured to reflect the orientation of the entire material to be tested. During injection molding, due to the shear distribution characteristics in the mold cavity, the material to be tested satisfies the condition that the dielectric constant gradually decreases from the center thickness to the edge, which satisfies the SPC model.

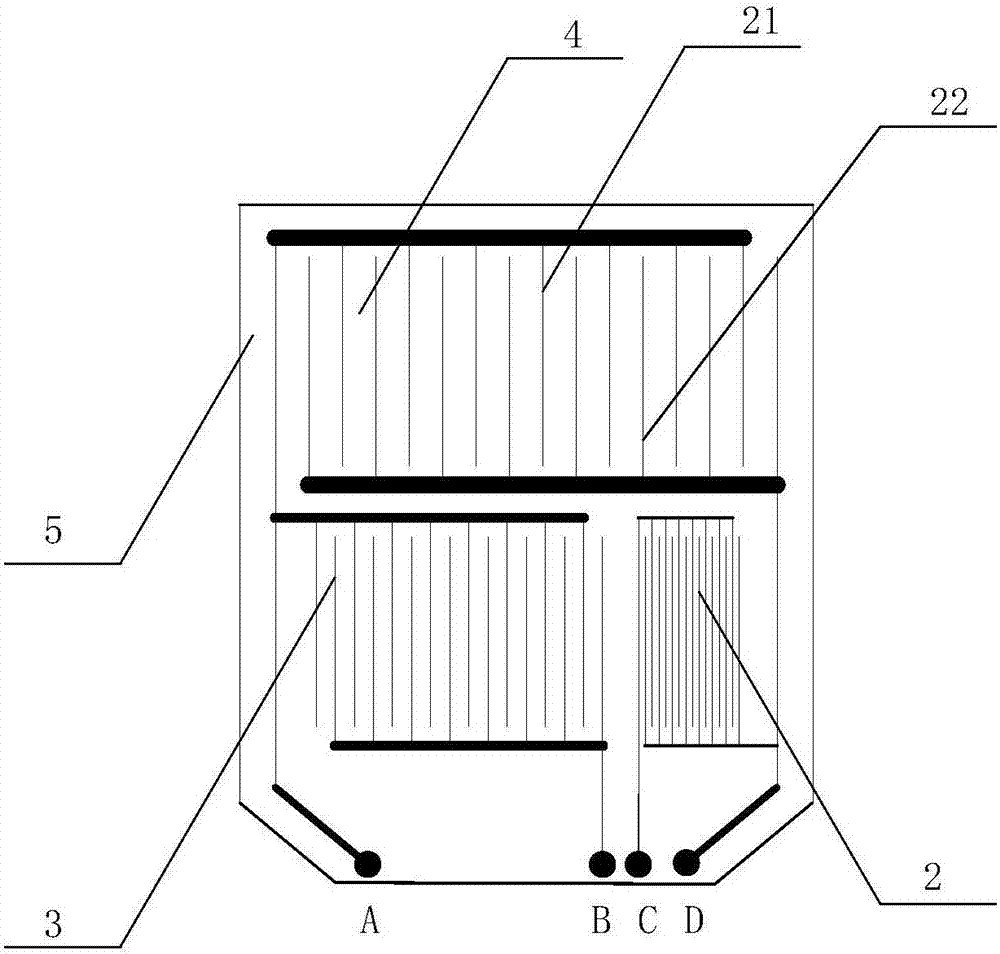

[0065] refer to figure 2 , the interdigital electrode probe in the present invention includes three groups of interdigital electrodes 2, 3, 4 with different detection depths, the electrode index N=16, and the finger length L=2cm. The interdigitated electrode group 2 has a pair of electrodes 21 and 22, which have the same strip electrode structure, are parallel to each other, and the ends are connected, and the ratio of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com