Long-wave infrared zoom lens unit

A zoom lens and long-wave infrared technology, applied in the field of long-wave infrared zoom lenses, can solve the problems that the details of objects cannot be clearly displayed, the range of temperature changes in the use environment is small, and there is no super wide field of view, and the thermal expansion coefficient can be achieved. Small, reduce the phenomenon of image plane drift, and compensate the effect of thermal difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

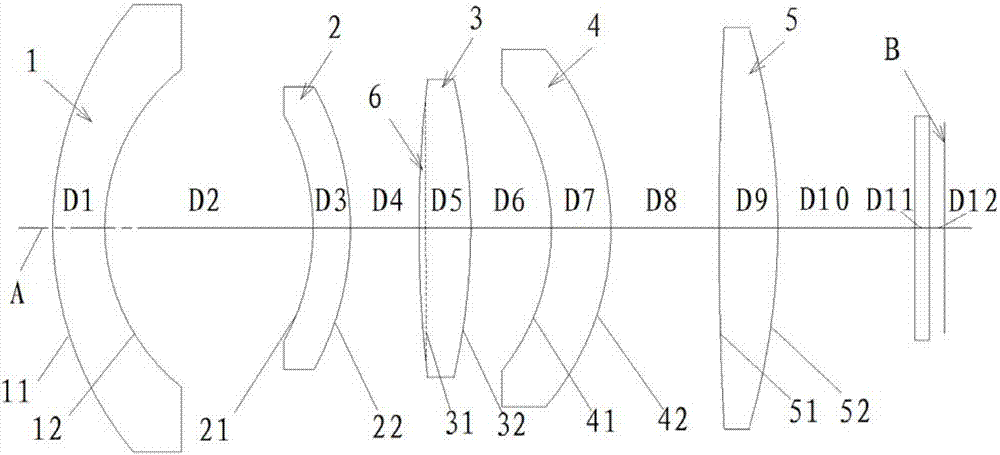

[0078] The focal length of the long-wave infrared zoom lens of the present invention is ft=8-12mm, and the F number of the optical system is FNO=1.1. The focal length of the first lens 1 is f1=-25.29mm; the focal length of the second lens 2 is f2=-50.78mm; the focal length of the third lens 3 is f3=16.74mm; the focal length of the fifth lens 5 is f5=20.85mm. BFL / ft=0.933, according to the relationship between the above-mentioned first lens 1, second lens 2, third lens 3, fifth lens 5 and the lens of the present invention, the data in Table 1 is calculated.

[0079] ft=8mm

ft=10mm

ft=12mm

f1 / ft=-3.16

f1 / ft=-2.53

f1 / ft=-2.11

f2 / ft=-6.35

f2 / ft=-5.08

f2 / ft=-4.23

f3 / ft=2.09

f3 / ft=1.67

f3 / ft=1.40

f5 / ft=2.61

f5 / ft=2.09

f5 / ft=1.74

[0080] Table I

[0081] In this embodiment, the specific parameters of the first lens 1, the second lens 2, the third lens 3, the fourth lens 4, and the fifth lens 5 are sho...

Embodiment 2

[0100] The focal length of the long-wave infrared zoom lens of the present invention is ft=8-12mm, and the F number of the optical system is FNO=1.1. The focal length of the first lens 1 is f1=-20.67mm; the focal length of the second lens 2 is f2=-24.61mm; the focal length of the third lens 3 is f3=12.03mm; the focal length of the fifth lens 5 is f5=16.78mm. BFL / ft=0.734, according to the relationship between the above-mentioned first lens 1, second lens 2, third lens 3, fifth lens 5 and the lens of the present invention, the data in Table 6 is calculated.

[0101] ft=8mm

ft=10mm

ft=12mm

f1 / ft=-2.58

f1 / ft=-2.07

f1 / ft=-1.72

f2 / ft=-3.08

f2 / ft=-2.46

f2 / ft=-2.05

f3 / ft=1.50

f3 / ft=1.20

f3 / ft=1.00

f5 / ft=2.10

f5 / ft=1.68

f5 / ft=1.40

[0102] Table six

[0103] In this embodiment, the specific parameters of the first lens 1, the second lens 2, the third lens 3, the fourth lens 4, and the fifth lens 5 are s...

Embodiment 3

[0124] The focal length of the long-wave infrared zoom lens of the present invention is ft=8-12mm, and the F number of the optical system is FNO=1.1. The focal length of the first lens 1 is f1=-25.34mm; the focal length of the second lens 2 is f2=-74.49mm; the focal length of the third lens 3 is f3=17.11mm; the focal length of the fifth lens 5 is f5=17.29mm. BFL / ft=1.24 According to the relationship between the first lens 1, the second lens 2, the third lens 3, and the fifth lens 5 and the lenses of the present invention, the data in Table 11 are calculated.

[0125] ft=8mm

ft=10mm

ft=12mm

f1 / ft=-3.17

f1 / ft=-2.53

f1 / ft=-2.11

f2 / ft=-9.31

f2 / ft=-7.45

f2 / ft=-6.21

f3 / ft=2.14

f3 / ft=1.71

f3 / ft=1.43

f5 / ft=2.16

f5 / ft=1.73

f5 / ft=1.44

[0126] Table Eleven

[0127] In this embodiment, the specific parameters of the first lens 1, the second lens 2, the third lens 3, the fourth lens 4, and the fifth lens 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com