A cmos device and its manufacturing method

A manufacturing method and device technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, transistors, etc., can solve problems such as the inability to achieve multi-threshold regulation, and achieve threshold regulation with little correlation, high control accuracy, and integration. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

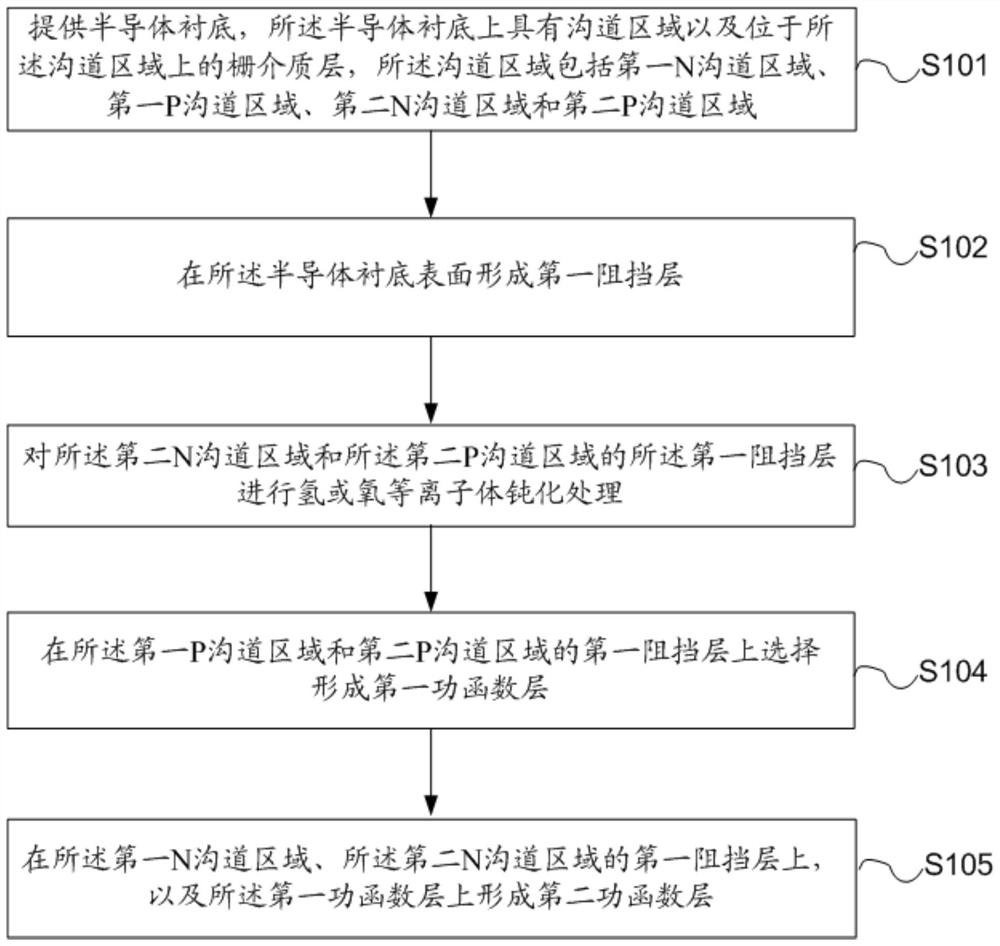

Method used

Image

Examples

Embodiment Construction

[0029] As mentioned in the background technology section, due to the space limitation and parasitic effects caused by size reduction in the prior art, higher requirements are put forward for the threshold adjustment of CMOS devices, and the traditional threshold adjustment method has not been well realized. Multi-threshold regulation.

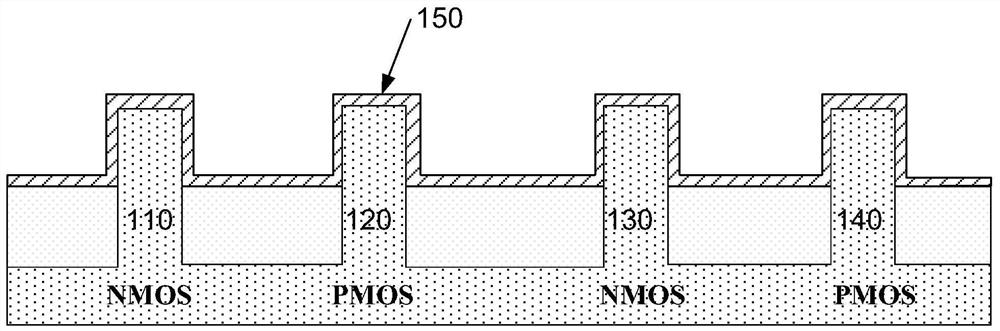

[0030] Specifically, the method for adjusting the threshold of a CMOS device in the prior art is: first deposit a barrier layer on the metal gates of the NMOS region and the PMOS region, then adjust the thickness of the barrier layer, then deposit a PMOS work function layer (PMOS WFL), and then change The thickness of the PMOSWFL is used to adjust the PMOS threshold; the NMOS work function layer (NMOS WFL) is then deposited, and the NMOS WFL is combined with the change in the thickness of the previous barrier layer to jointly adjust the NMOS threshold. Since the NMOS threshold adjustment process in the existing method needs to be divided into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com