Patents

Literature

40results about How to "Simple integration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

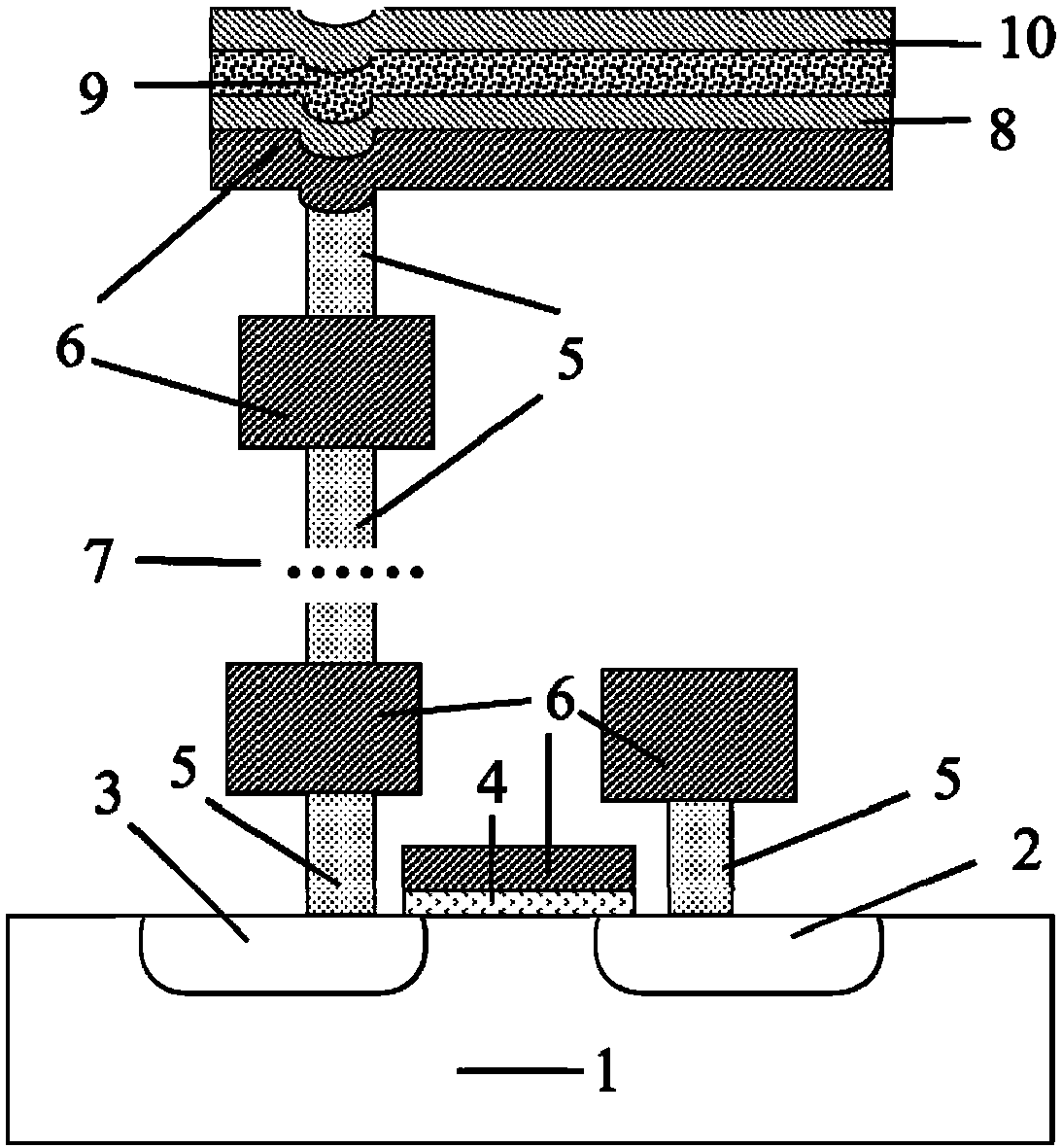

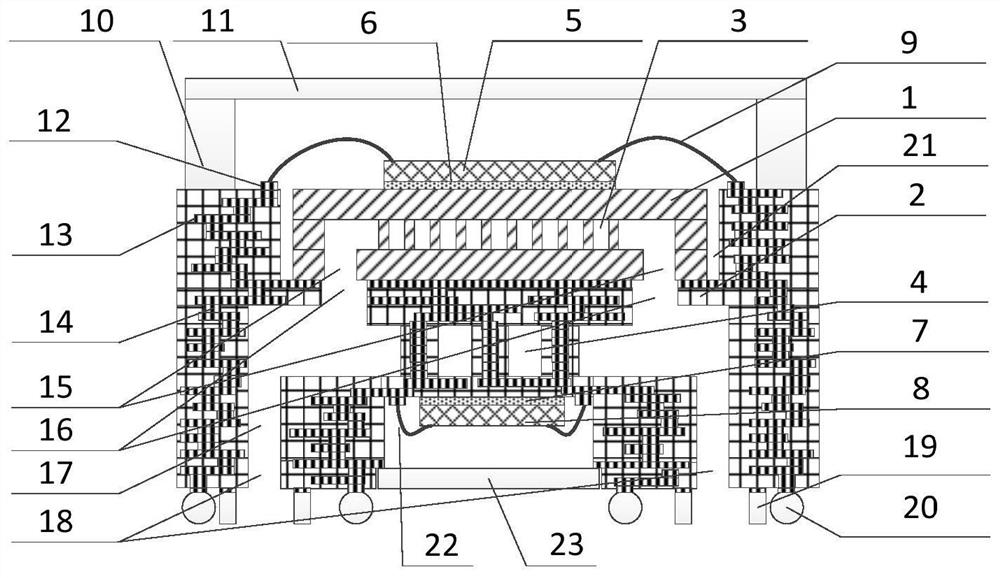

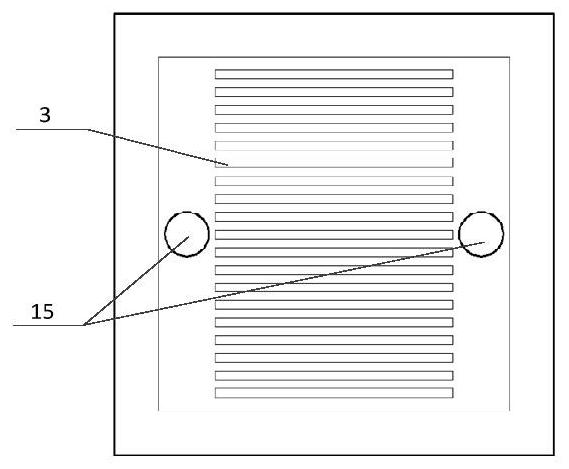

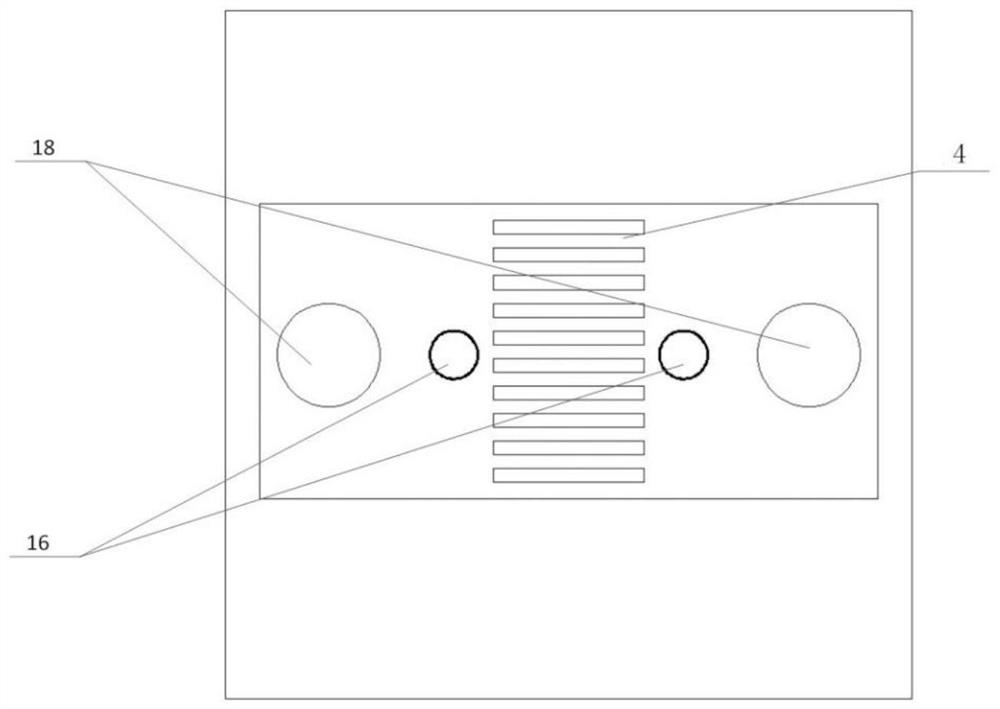

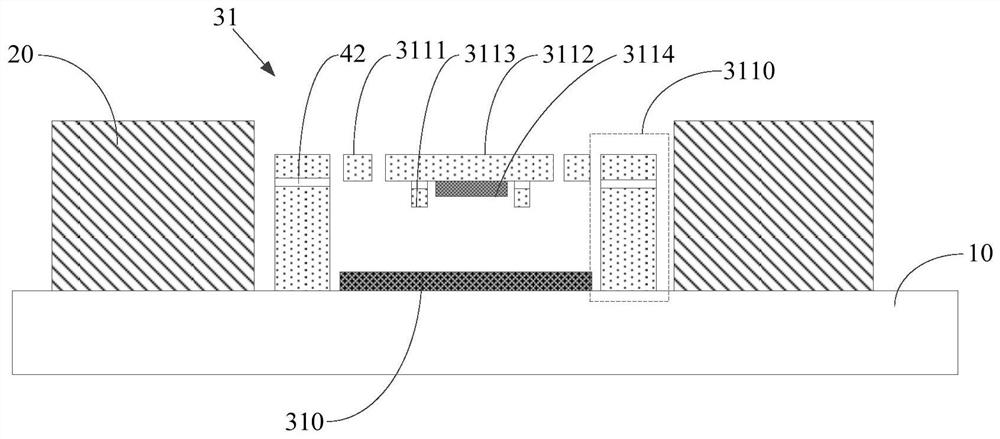

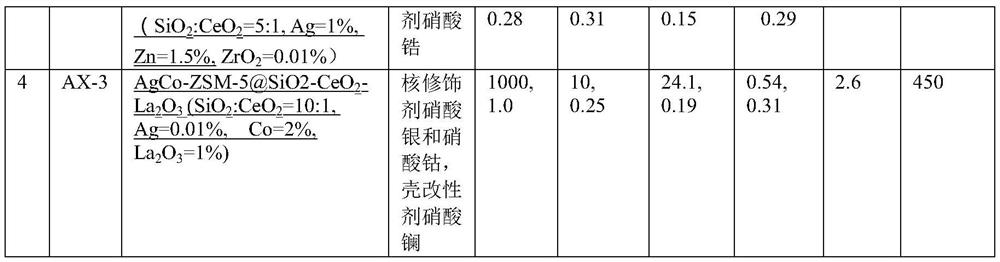

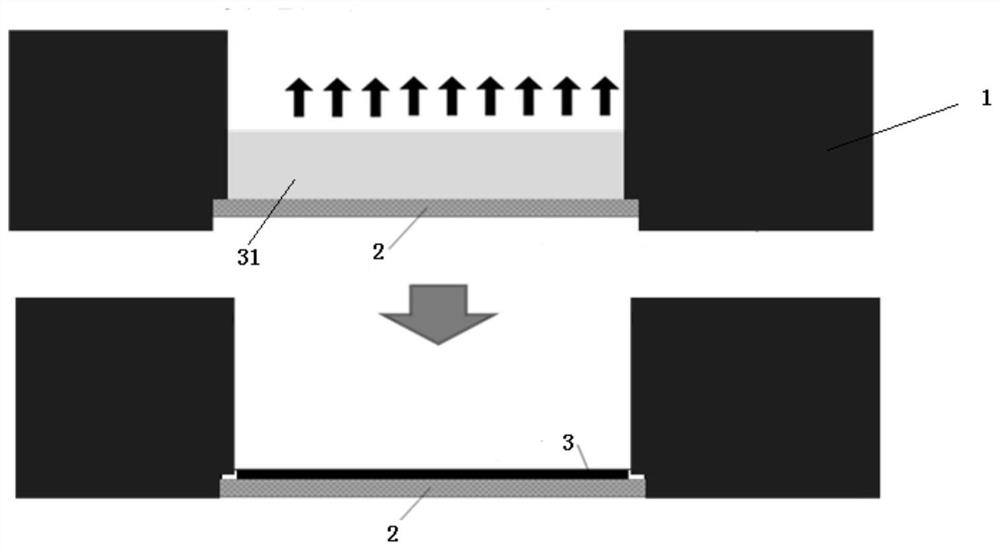

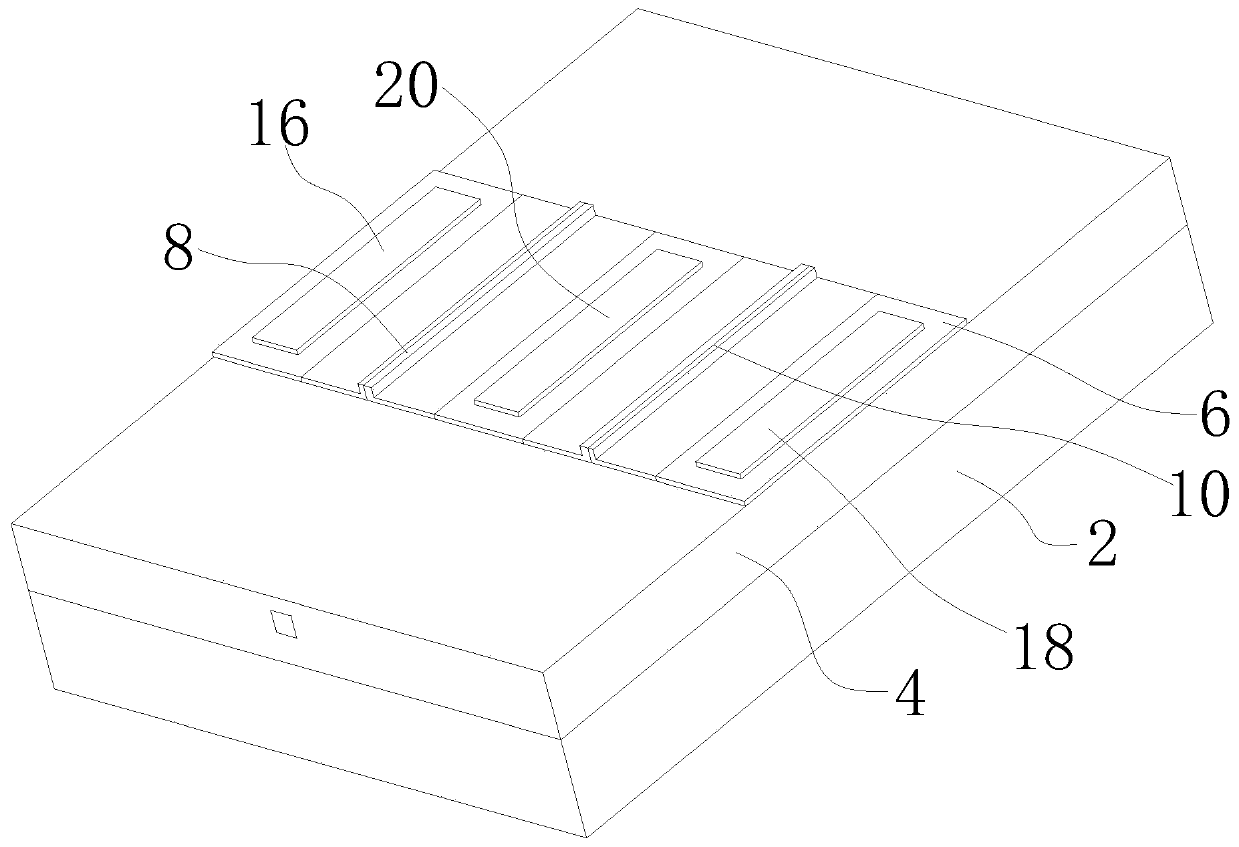

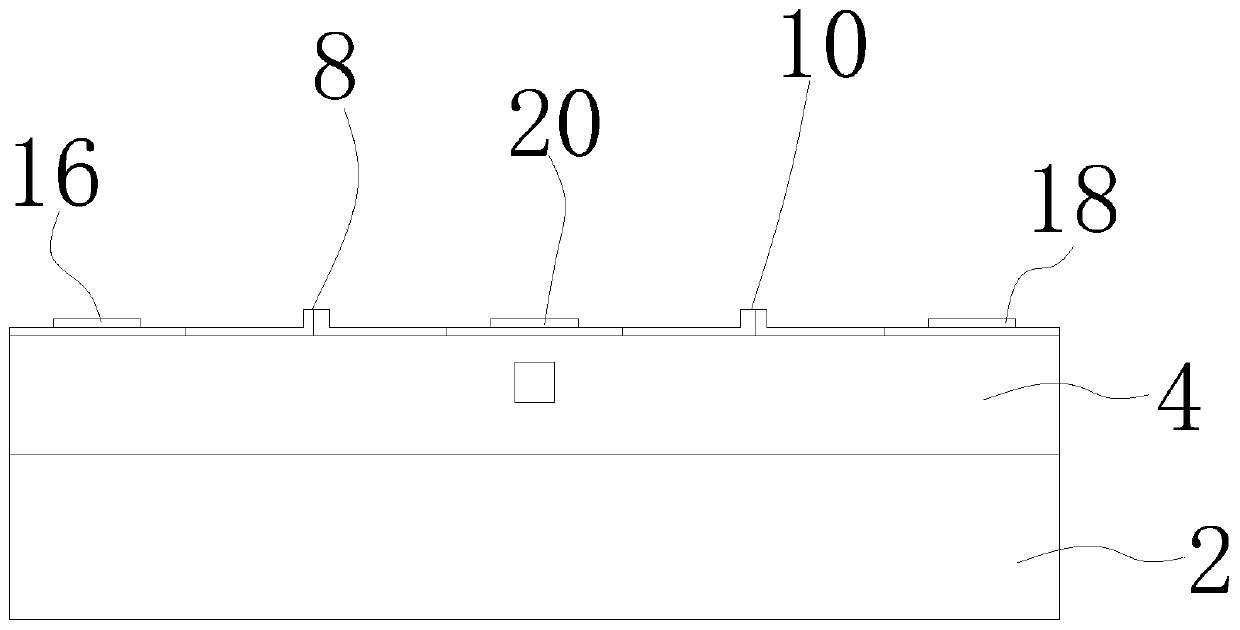

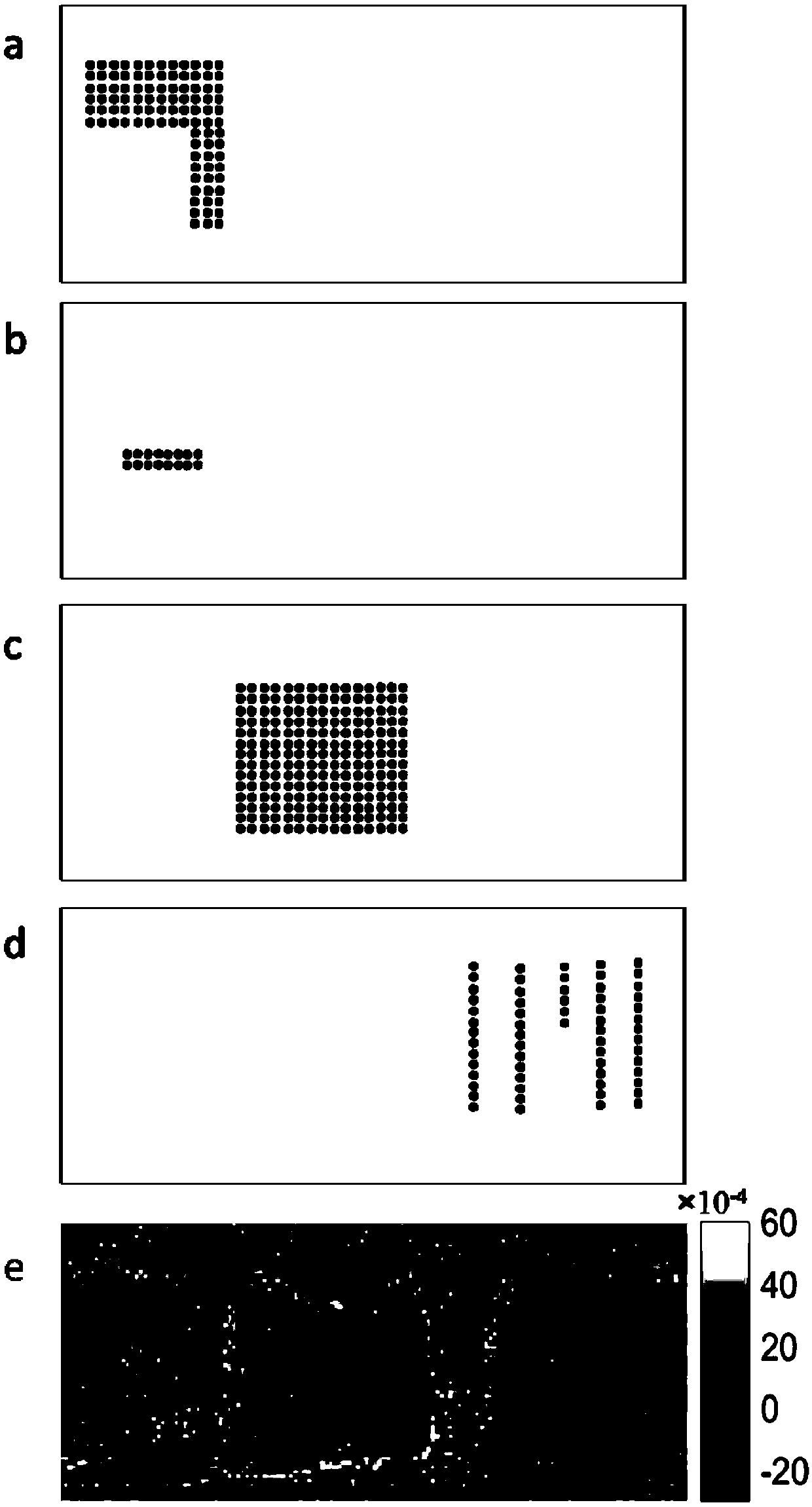

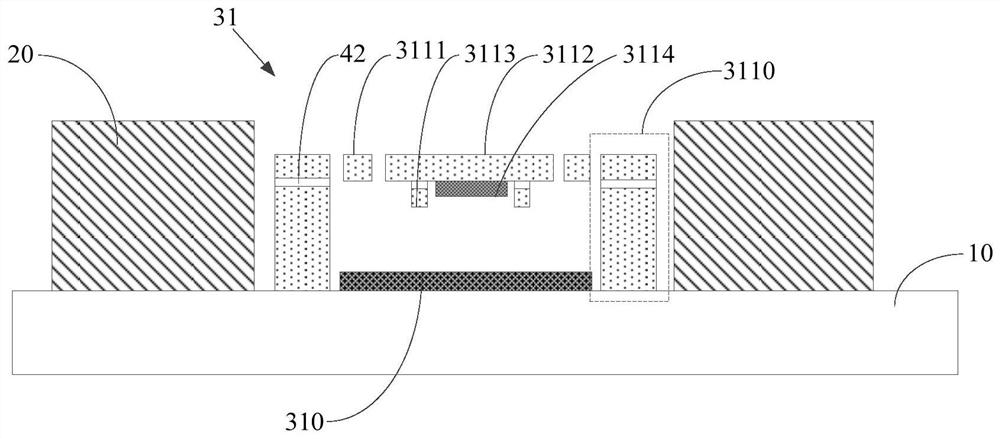

MEMS (Micro Electro Mechanical System) film capacitive type multi-parameter sensor structure and integrated manufacturing method thereof

ActiveCN102798403AReduce volumeSimple integration processDecorative surface effectsSolid-state devicesSurface micromachiningCapacitance

The invention discloses an MEMS (Micro Electro Mechanical System) film capacitive type multi-parameter sensor structure and an integrated manufacturing method thereof. An MEMS carrying substrate is provided with MEMS film capacitive type pressure, temperature and humidity sensors which are arranged side by side. Electrodes, sacrificial layers, sensitive layers, sensitive films and protective layers of the three sensors adopt mutually matching structures and materials and therefore can be manufactured through an integrated surface micro-processing technology. The multi-parameter sensor structure and the integrated manufacturing method provided by the invention have the advantages of reducing volume of components, simplifying technical steps and being capable of decreasing cost of sensor products to a certain extent. In addition, the wholly capacitive structure adds application potential of the MEMS film capacitive type multi-parameter sensor structure in an inductive coupling based passive wireless sensing system.

Owner:中科芯未来微电子科技成都有限公司

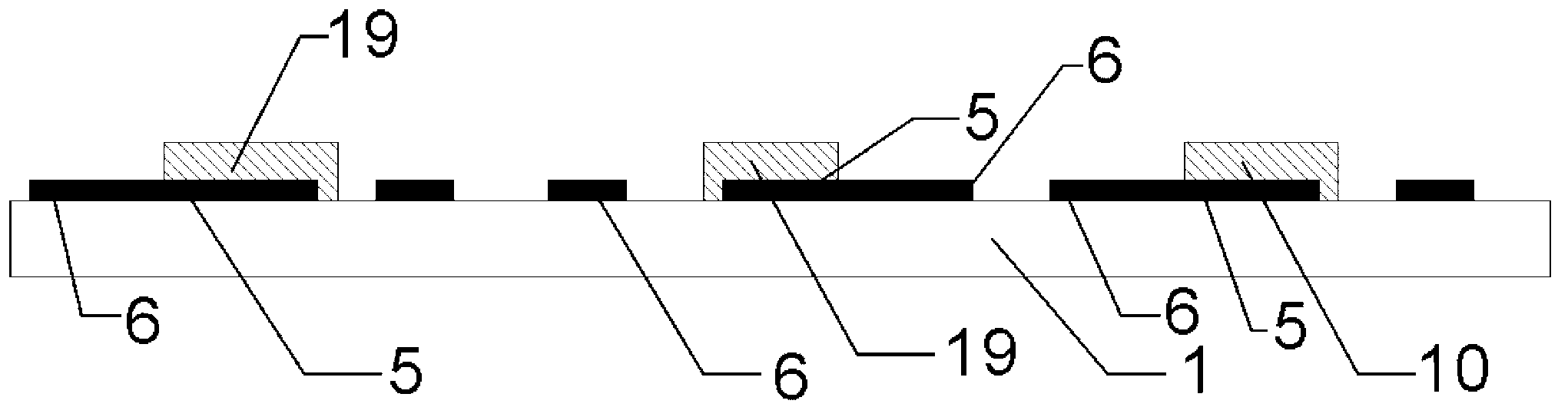

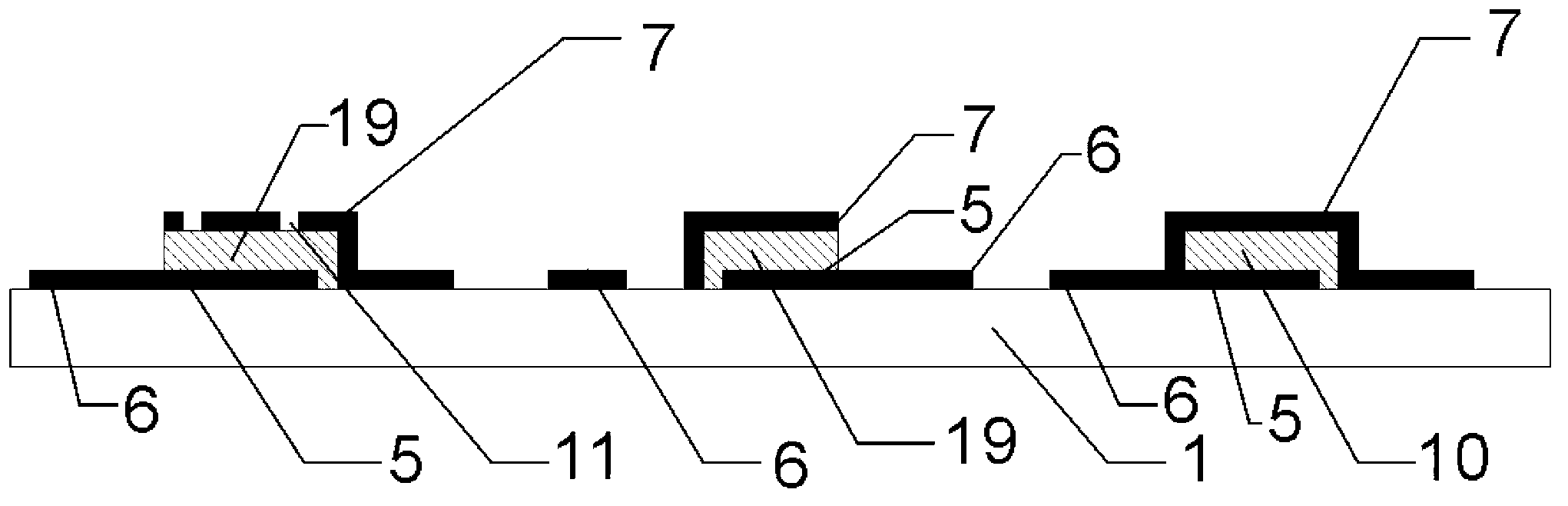

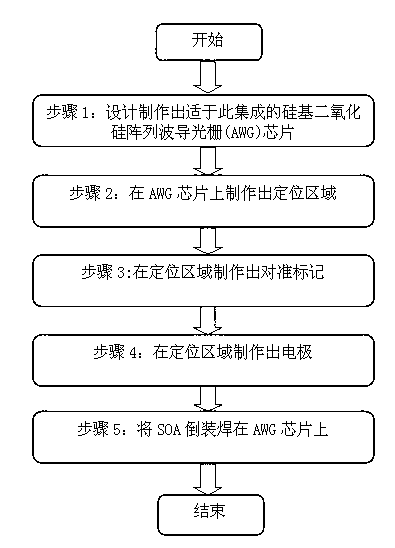

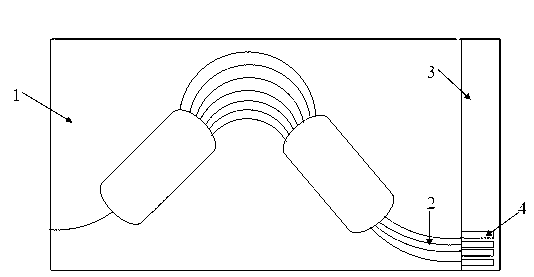

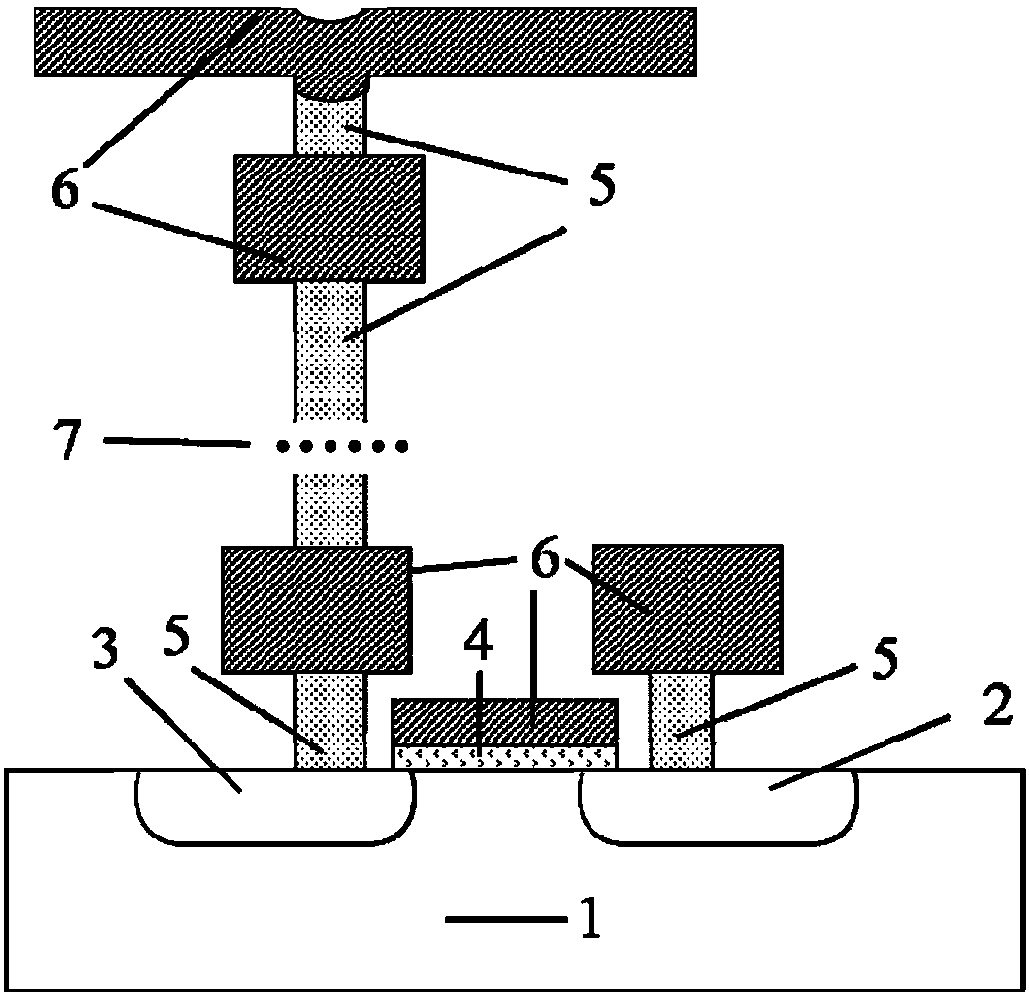

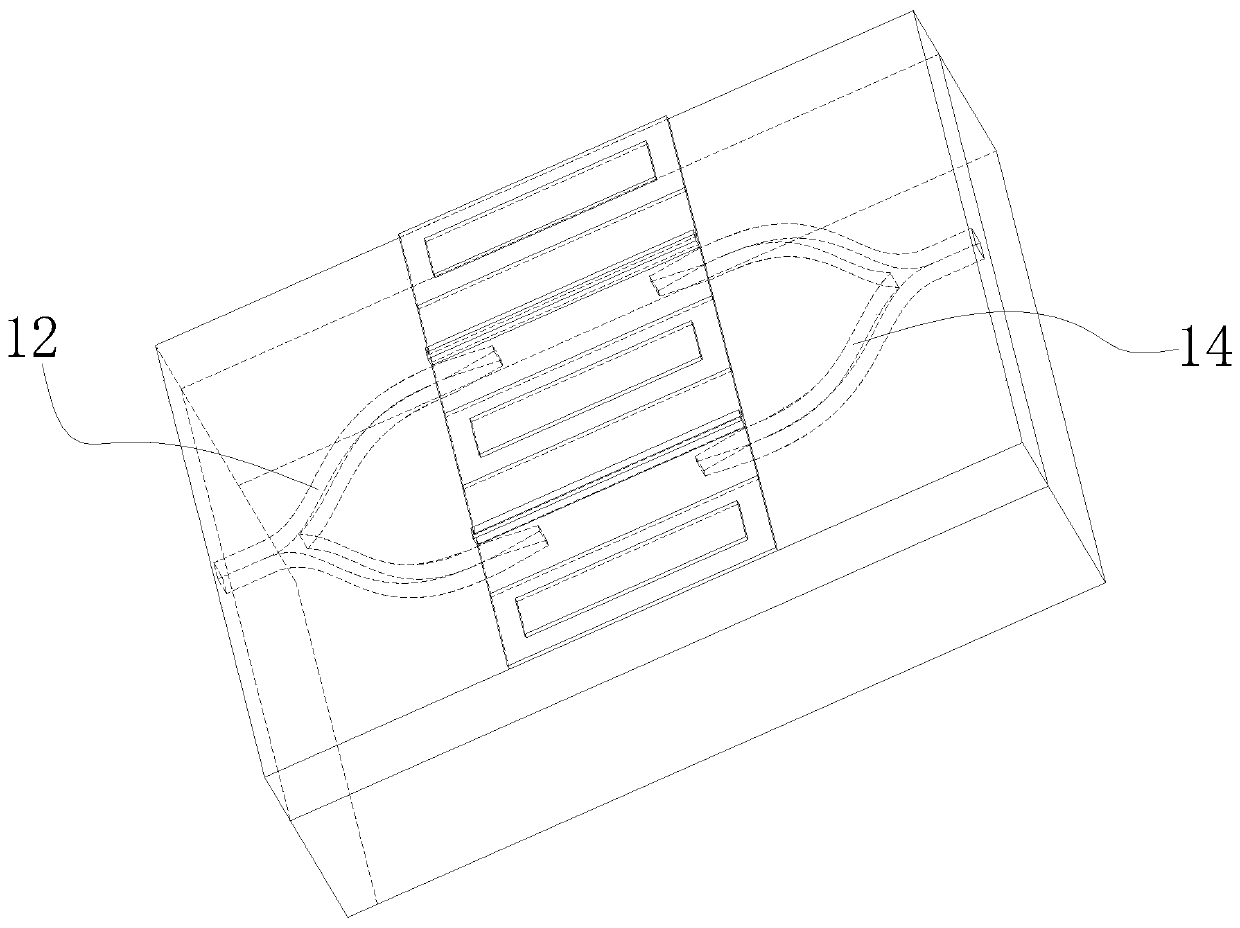

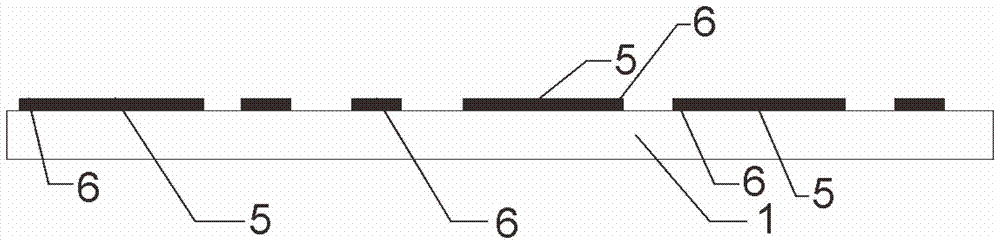

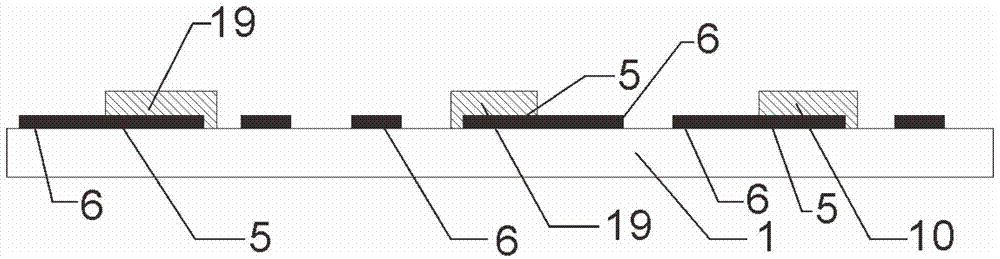

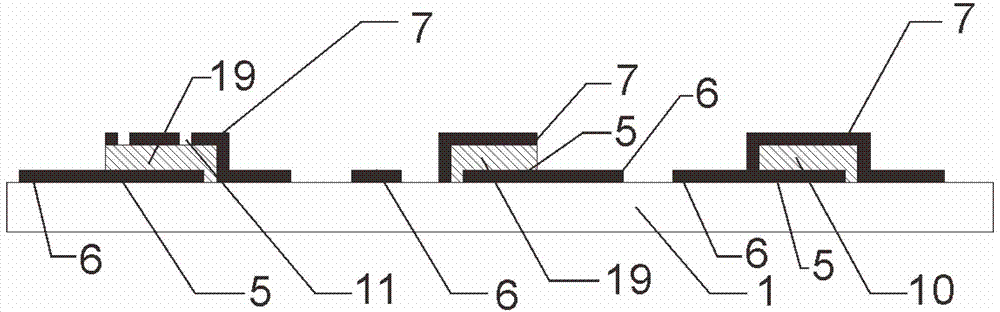

Method for flip integration of array beam guide grate chip and semiconductor optical amplifier chip

InactiveCN103001120AImprove reliabilityImprove integration efficiencyLaser detailsLaser optical resonator constructionGratingEngineering

The invention discloses a method for flip integration of an array beam guide grate chip and a semiconductor optical amplifier chip. The method comprises steps of designing and producing the array beam guide grate chip which is suitable to integration; producing a positioning region on the array beam guide grate chip; producing an aligning mark in the positioning region of the array beam guide grate chip; producing an electrode in the positioning region of the array beam guide grate chip; and welding the semiconductor optical amplifier chip to the positioning region of the array beam guide grate chip in a flip mode after aligning the aligning mark of the semiconductor optical amplifier chip to the aligning mark of the positioning region. By the aid of the method, a semiconductor optical amplifier (SOA) chip can be integrated to the substrate of an Arrayed Waveguide Grating (AWG), the reliability of the device is improved, the integration process is simplified and the integration effectively is improved.

Owner:GUANGXUN SCI & TECH WUHAN

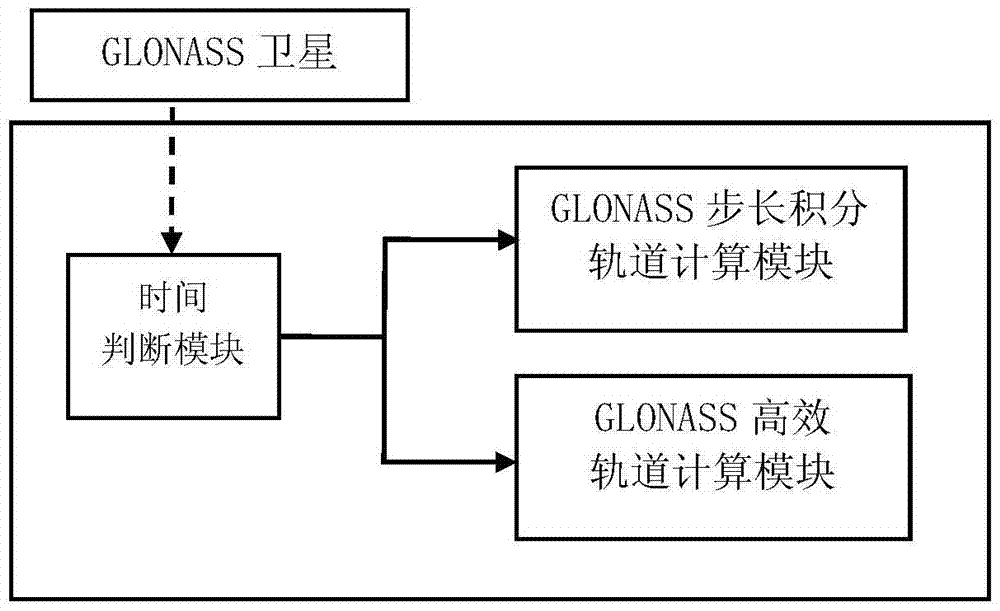

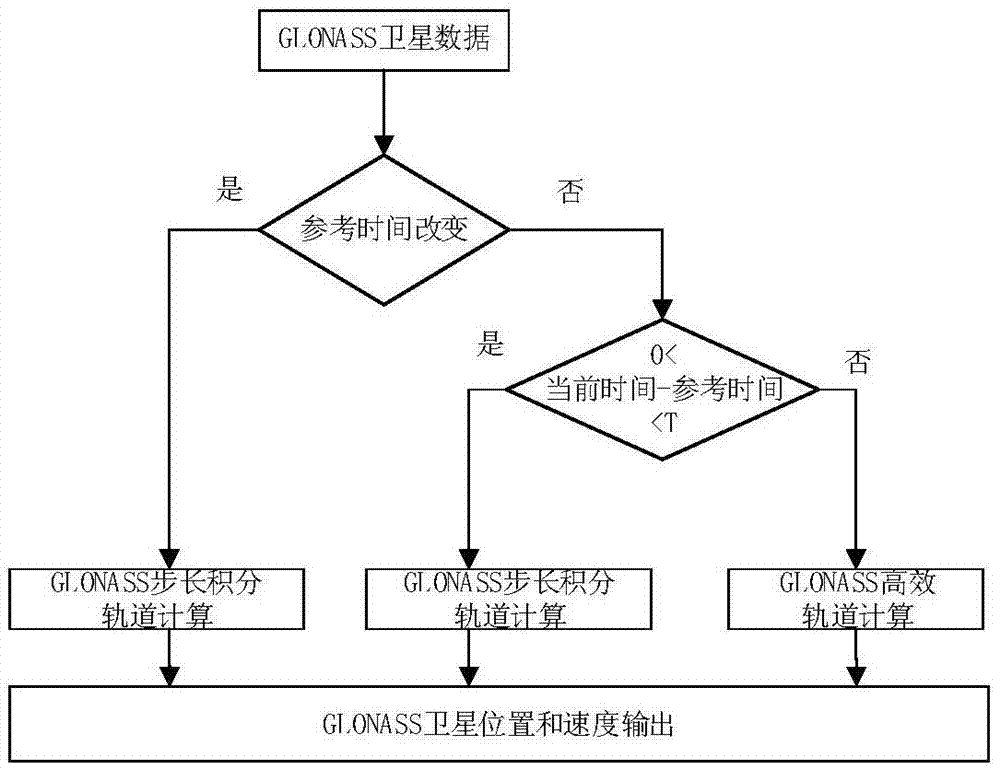

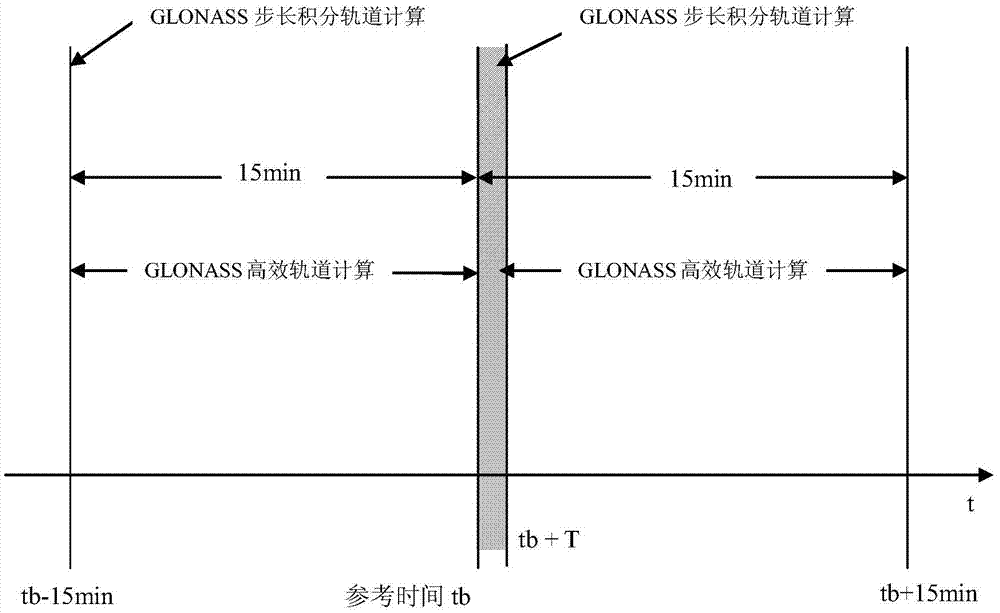

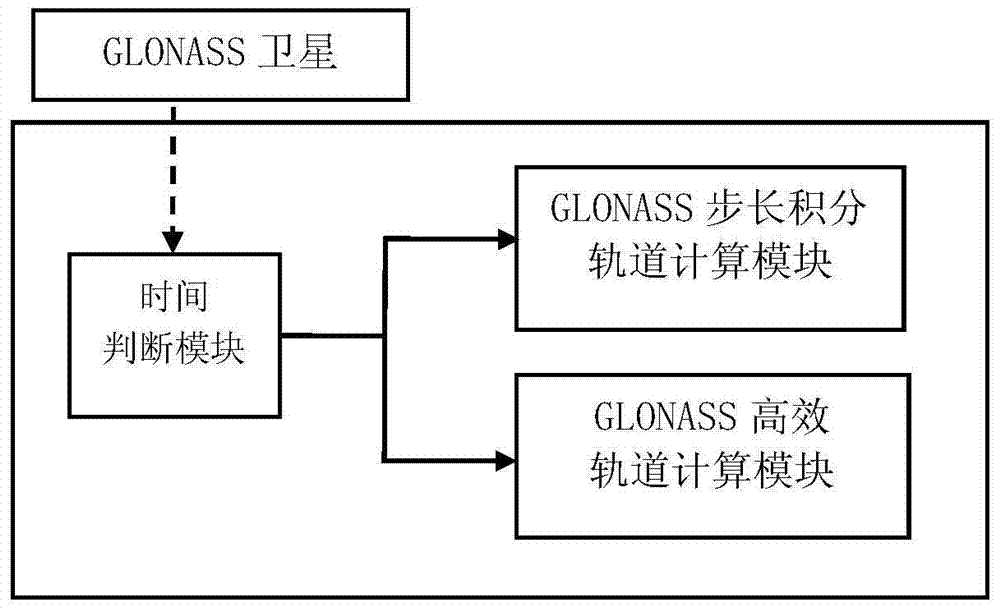

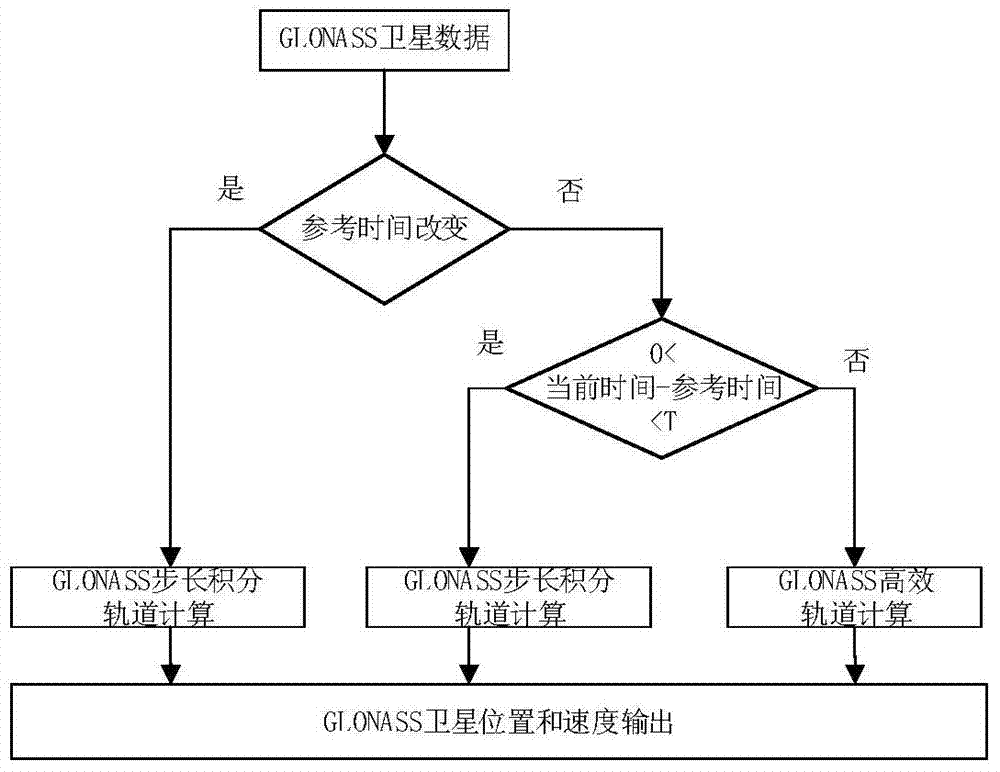

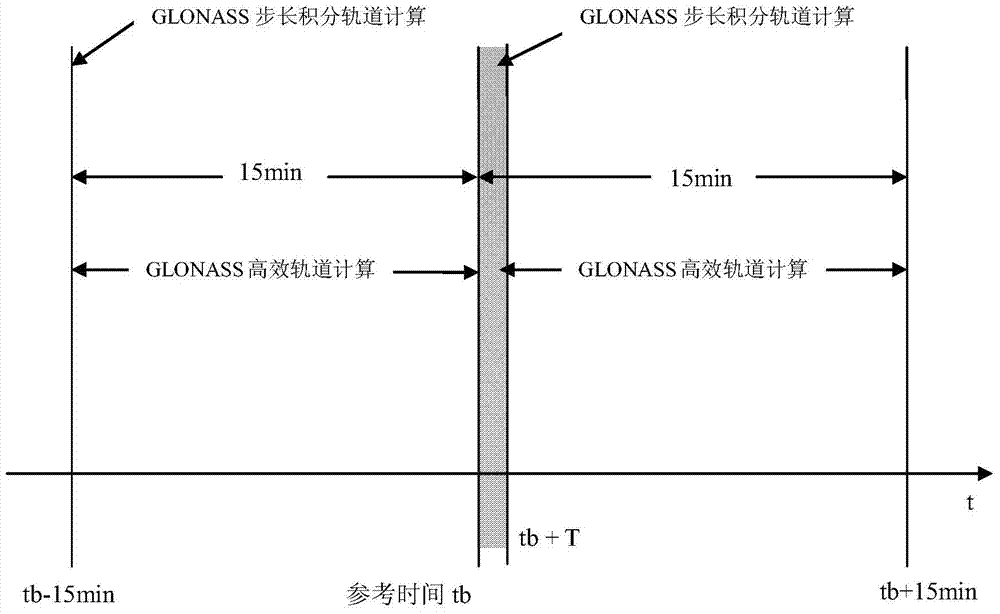

GLONASS satellite orbit calculating method and system thereof

ActiveCN105445766ASave resource callsSimple integration processSatellite radio beaconingSatellite orbitSatellite positioning

The invention discloses a GLONASS satellite orbit calculating method and a system thereof. The method comprises the following steps of capturing a GLONASS satellite broadcast signal, converting into GLONASS satellite data and transmitting to a time determination module; determining whether satellite reference time tb in the GLONASS satellite data is different from current reference time tb of a positioning system, if the satellite reference time tb in the GLONASS satellite data is different from the current reference time tb of the positioning system, updating the reference time tb and satellite positioning data; otherwise, keeping using the reference time tb and the satellite positioning data; transmitting the GLONASS satellite data to a GLONASS step integration orbit calculation module and finally calculating a GLONASS satellite position and a speed; comparing satellite reference time to current satellite time, if the current time is greater than the satellite reference time and a difference is in one sampling epoch interval, recalibrating the GLONASS satellite position and the speed, otherwise, selecting a GLONASS high-efficiency orbit calculation module and finally calculating the GLONASS satellite position and the speed.

Owner:惠州市峰华经纬科技有限公司

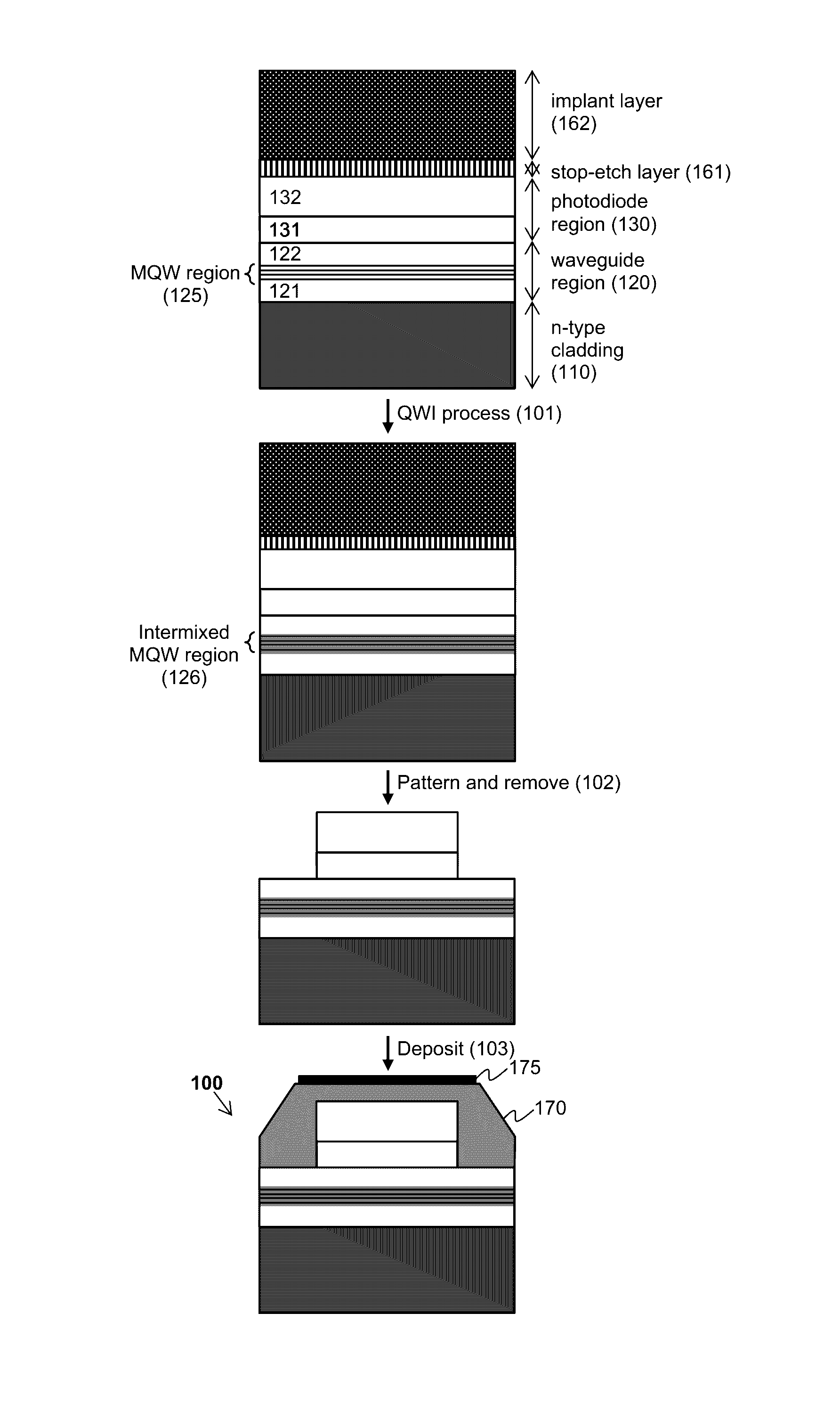

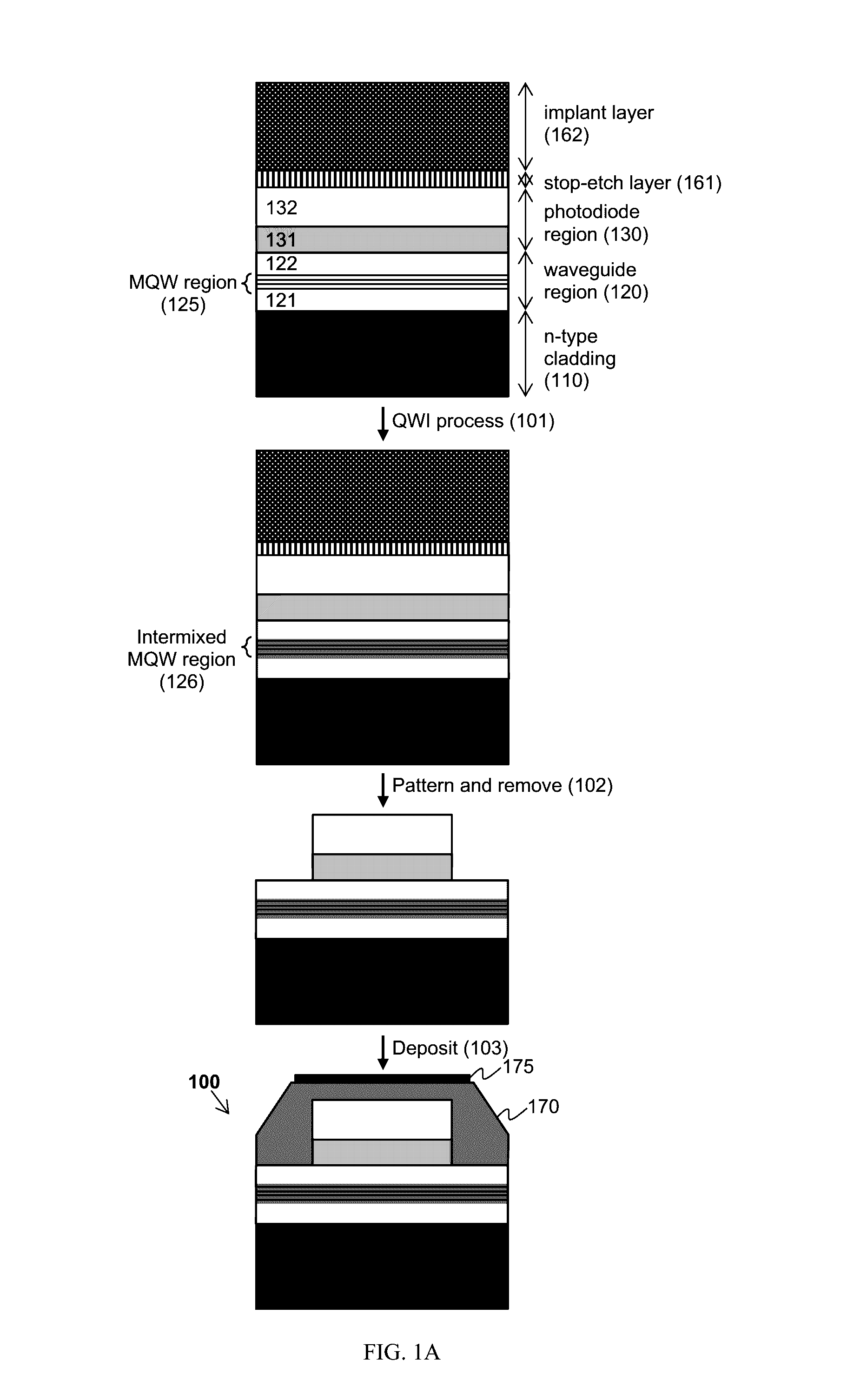

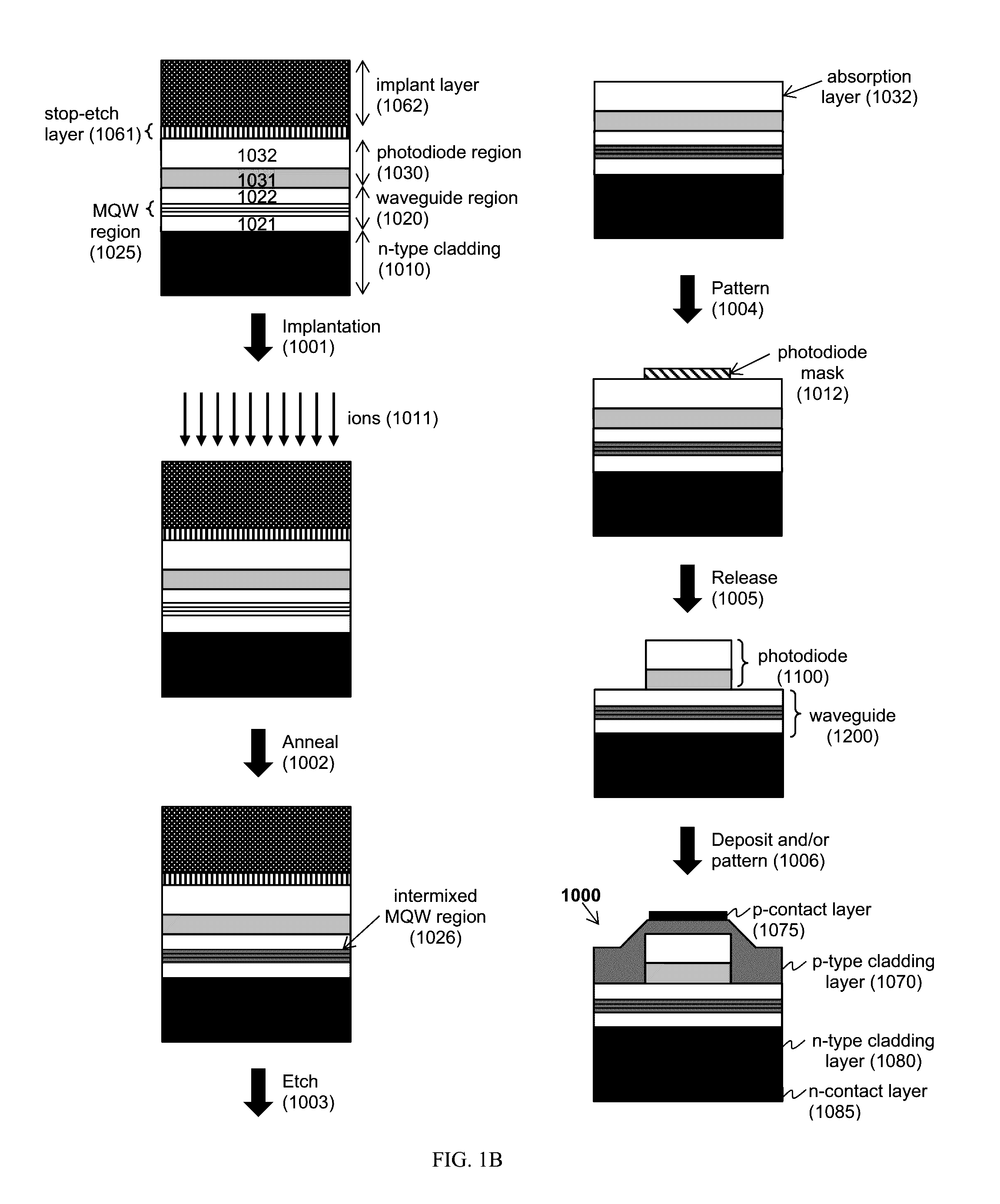

Guided-wave photodiode using through-absorber quantum-well-intermixing and methods thereof

ActiveUS9477040B1Reduce material lossSimple integration processOptical waveguide light guideSemiconductor devicesPhase modulationQuantum well

The present invention includes a high-speed, high-saturation power detector (e.g., a photodiode) compatible with a relatively simple monolithic integration process. In particular embodiments, the photodiode includes an intrinsic bulk absorption region, which is grown above a main waveguide core including a number of quantum wells (QWs) that are used as the active region of a phase modulator. The invention also includes methods of fabricating integrated photodiode and waveguide assemblies using a monolithic, simplified process.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

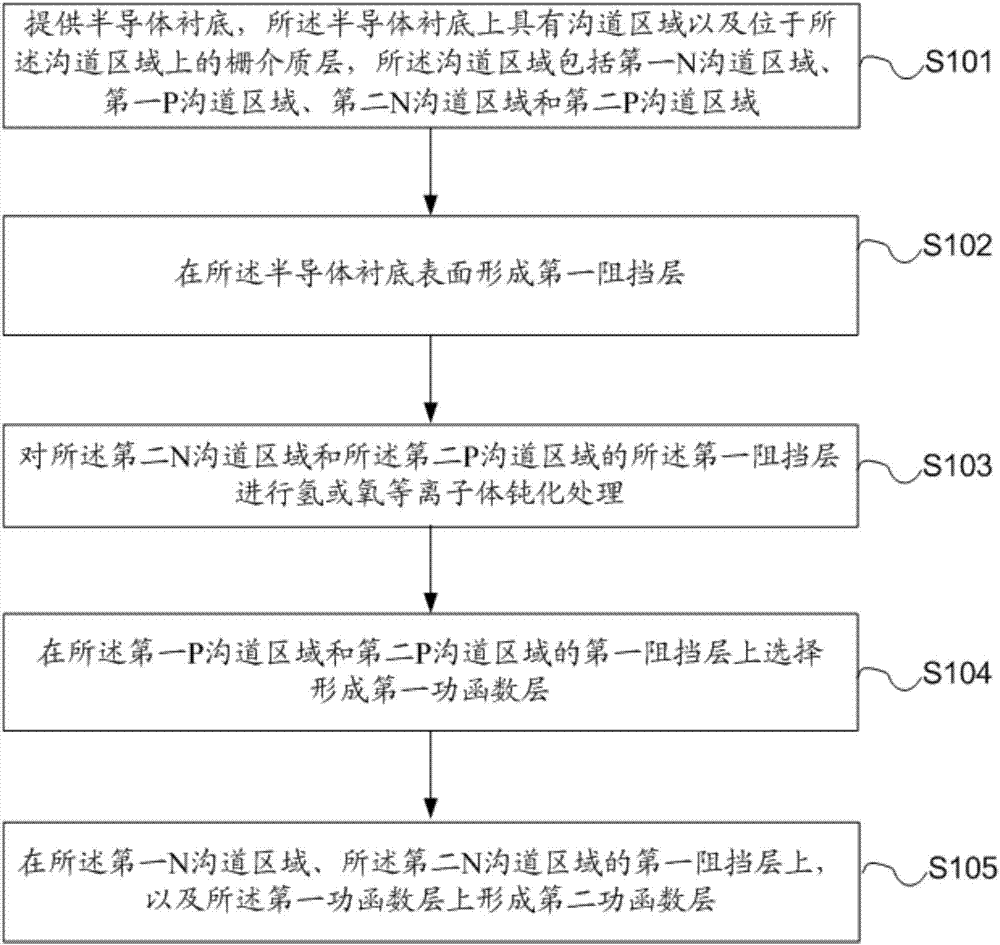

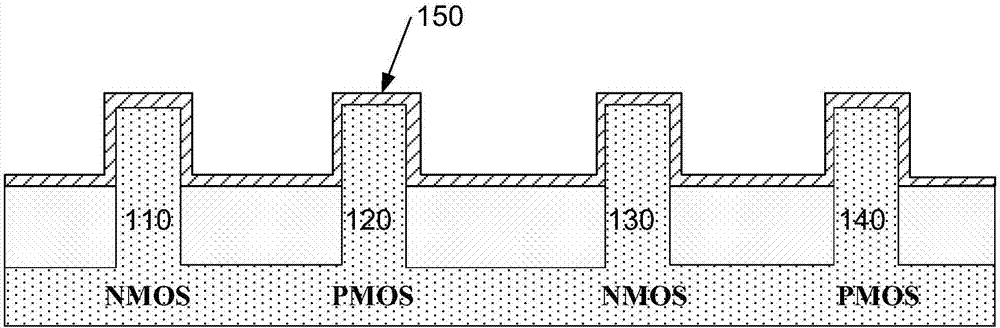

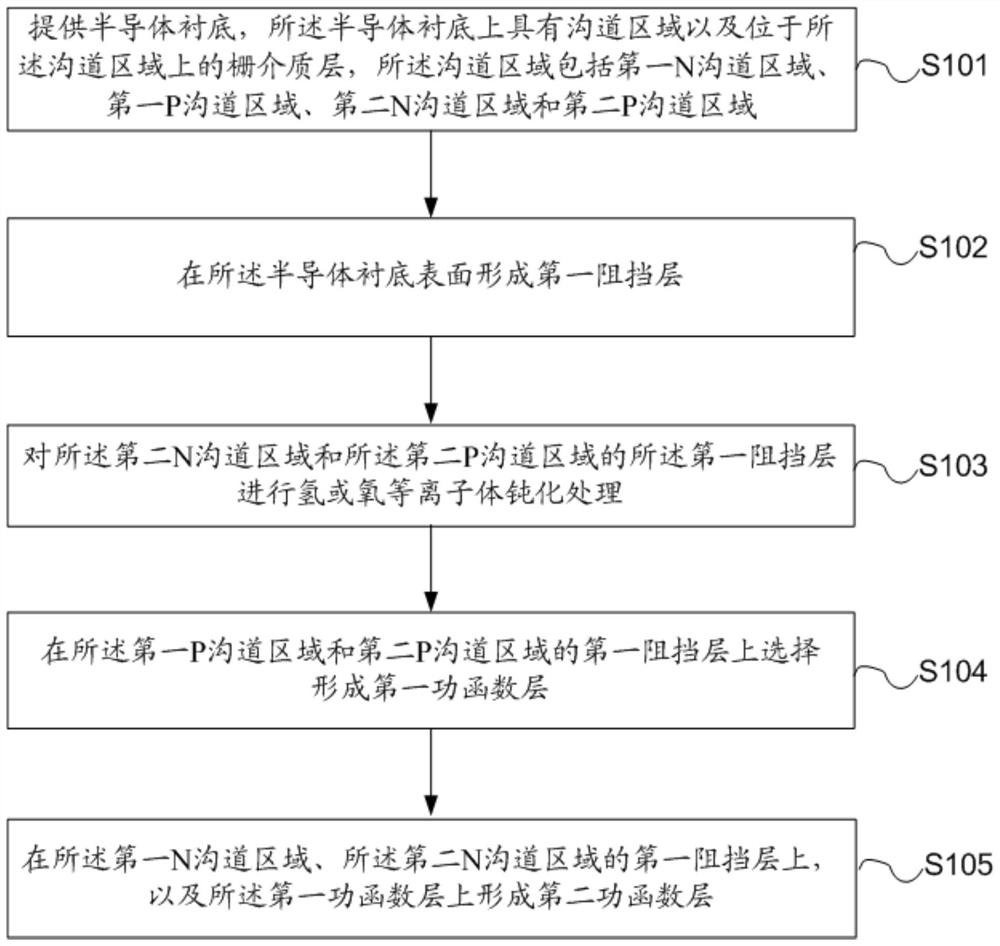

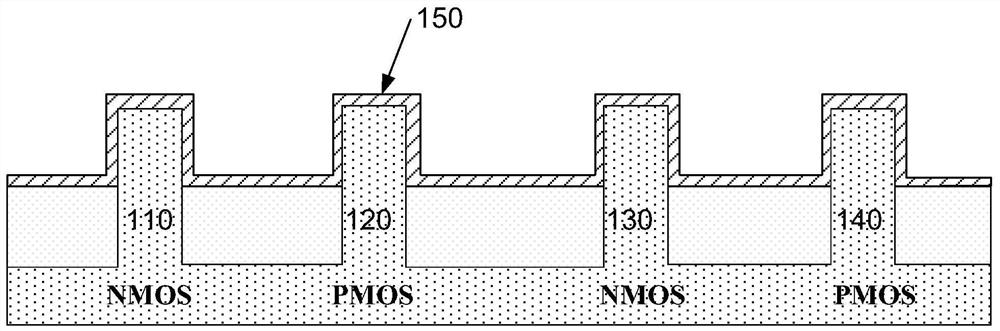

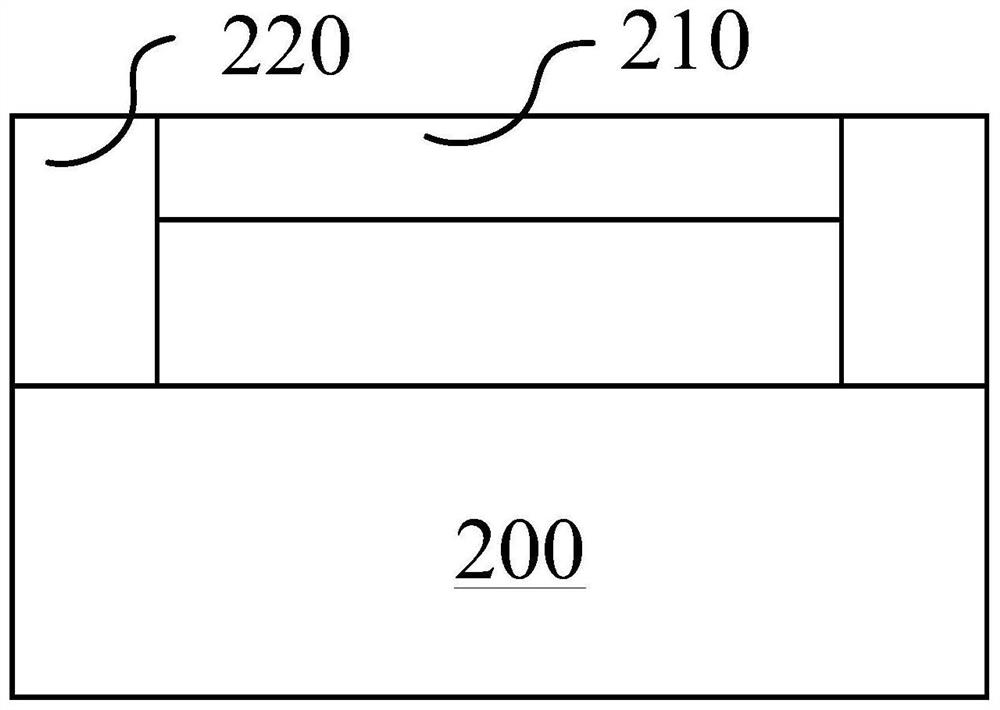

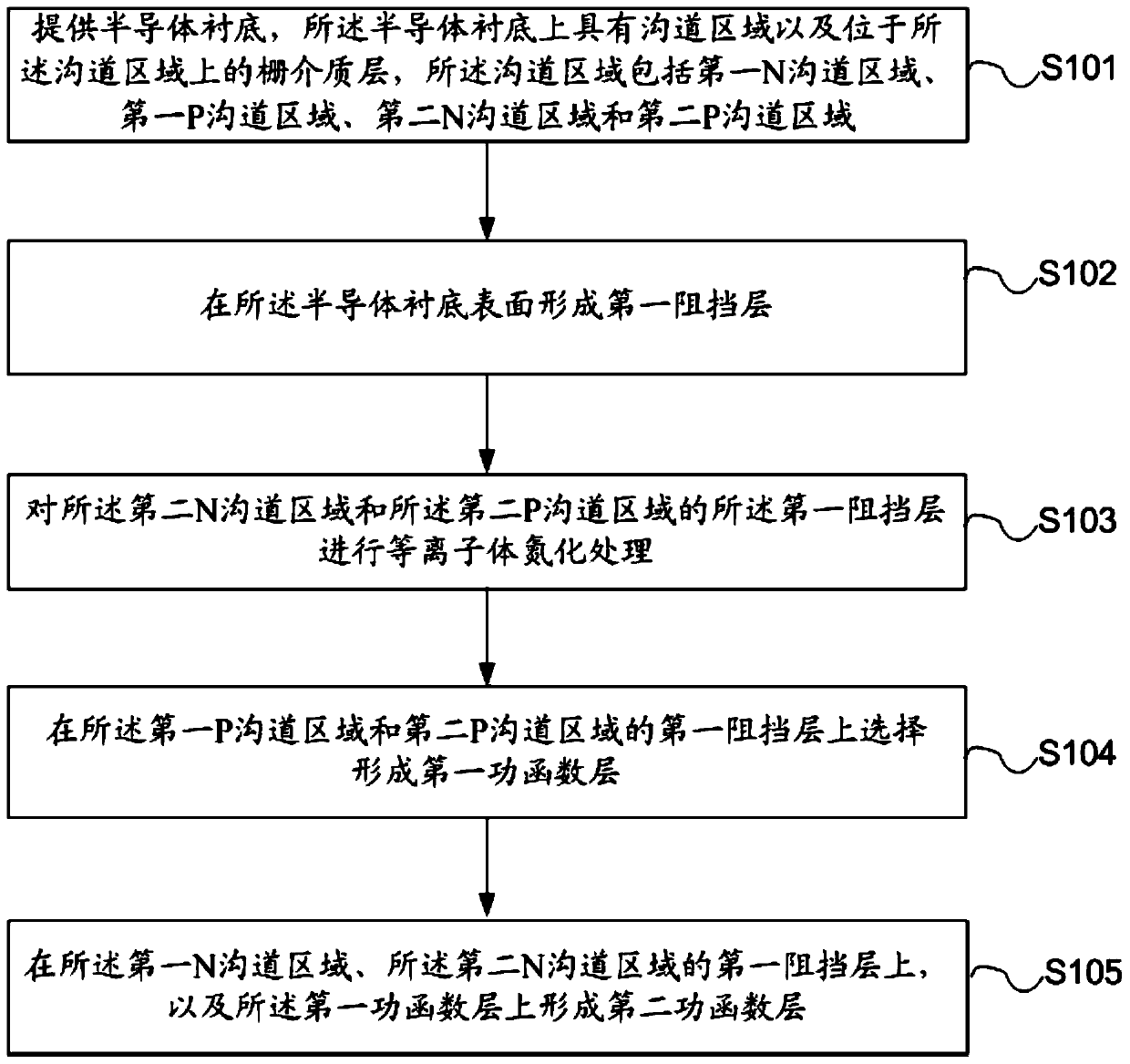

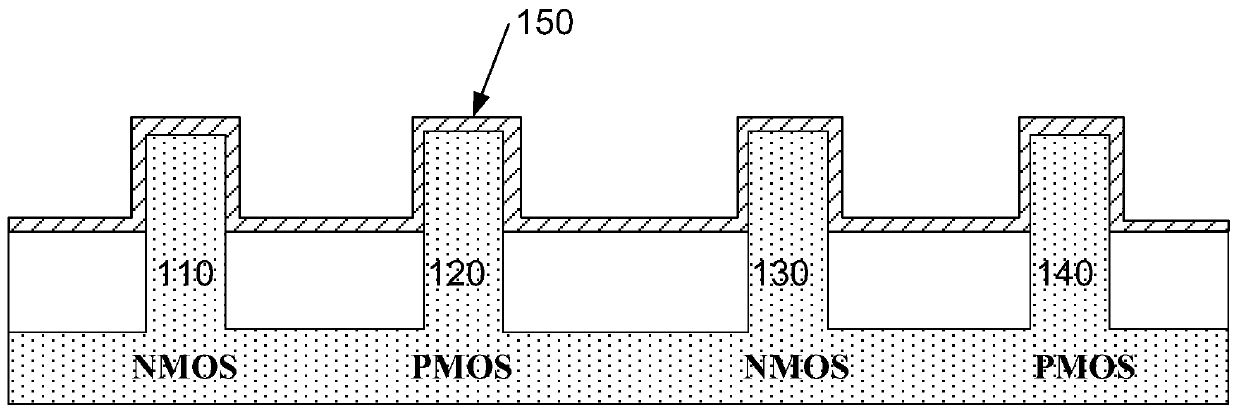

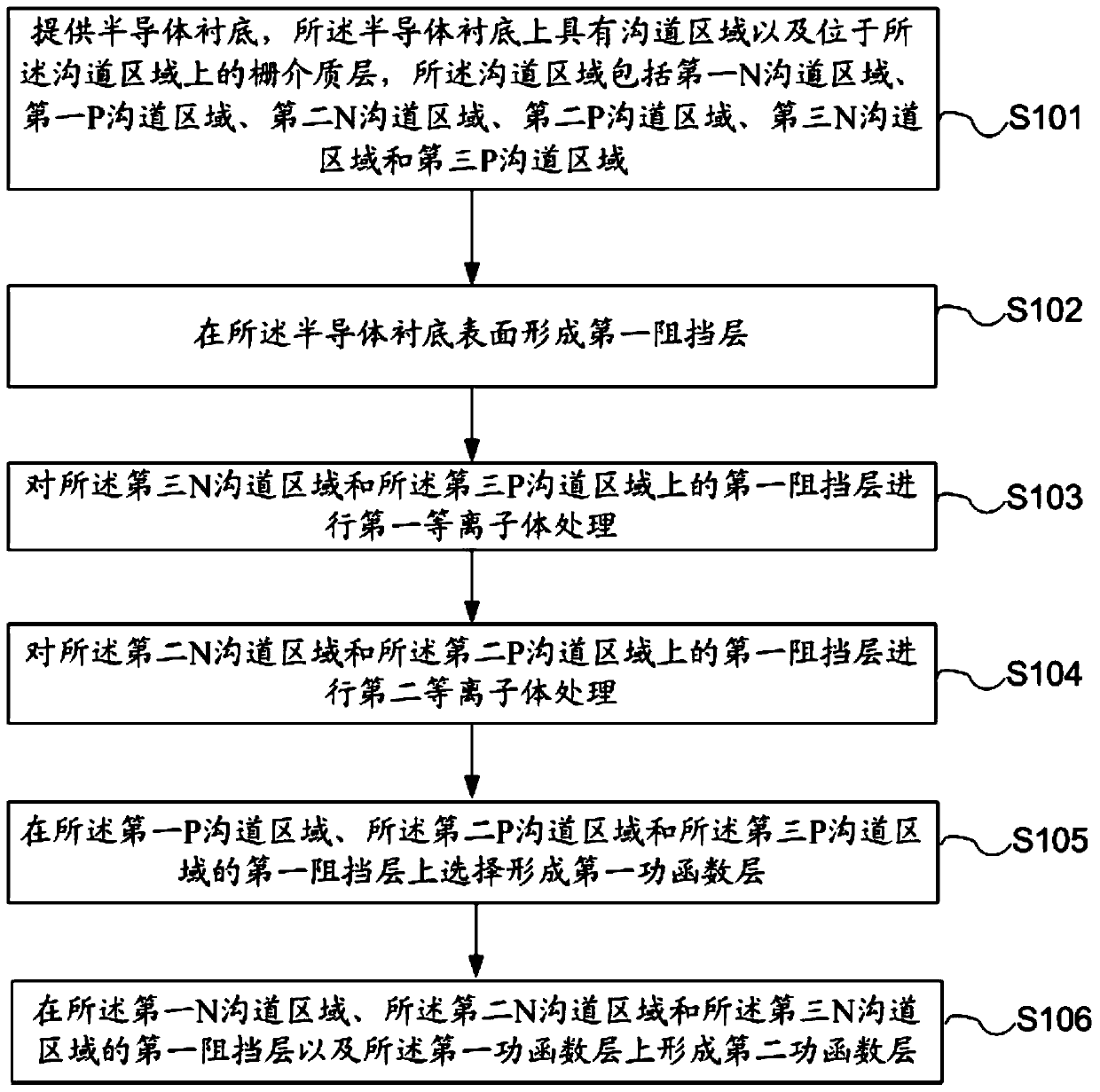

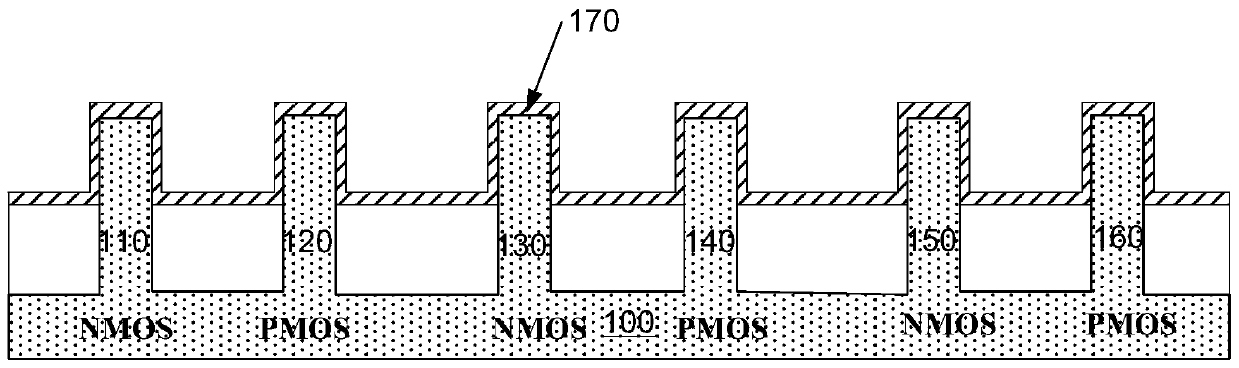

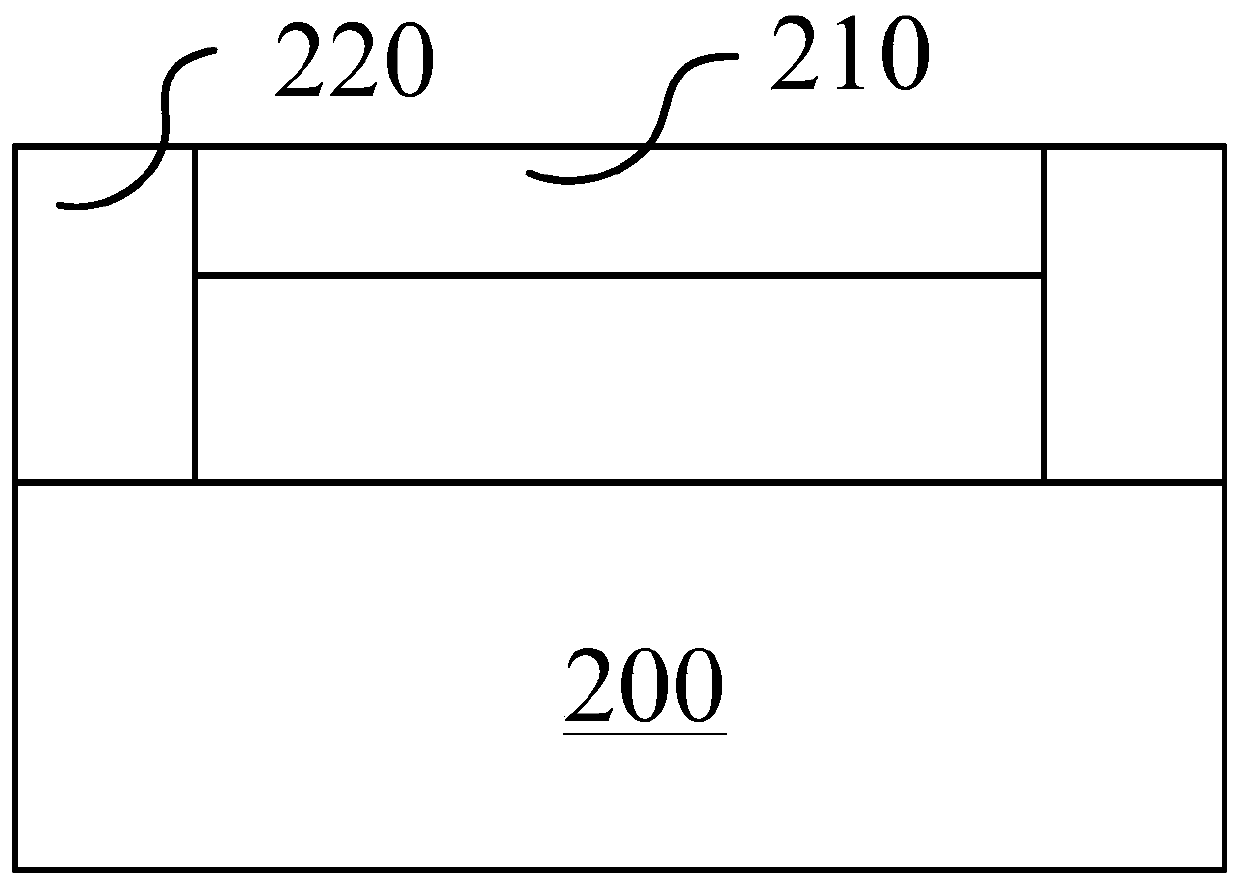

CMOS device and fabrication method thereof

ActiveCN107481971AThreshold adjustment association has little effectSimple integration processTransistorSemiconductor/solid-state device manufacturingCMOSHydrogen

The invention provides a CMOS device and a fabrication method thereof. The method comprises steps: a semiconductor substrate is provided; a first blocking layer is formed on the surface of the semiconductor substrate; hydrogen or oxygen plasma passivation processing is carried out on the first blocking layer on a second N channel area and a second P channel area; a first work function layer is formed on the first blocking layer on a first P channel area and the second P channel area; a second work function layer is formed on the first blocking layer on a first N channel area and the second N channel area and the first work function layer; and / or hydrogen or oxygen plasma passivation processing is carried out on the first blocking layer on the second N channel area and the first work function layer on the second P channel area. The method is high in threshold adjustment control precision, the process flexibility is high, and the method is simple and easy to operate and is more suitable for multi-threshold regulation on a small-size device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

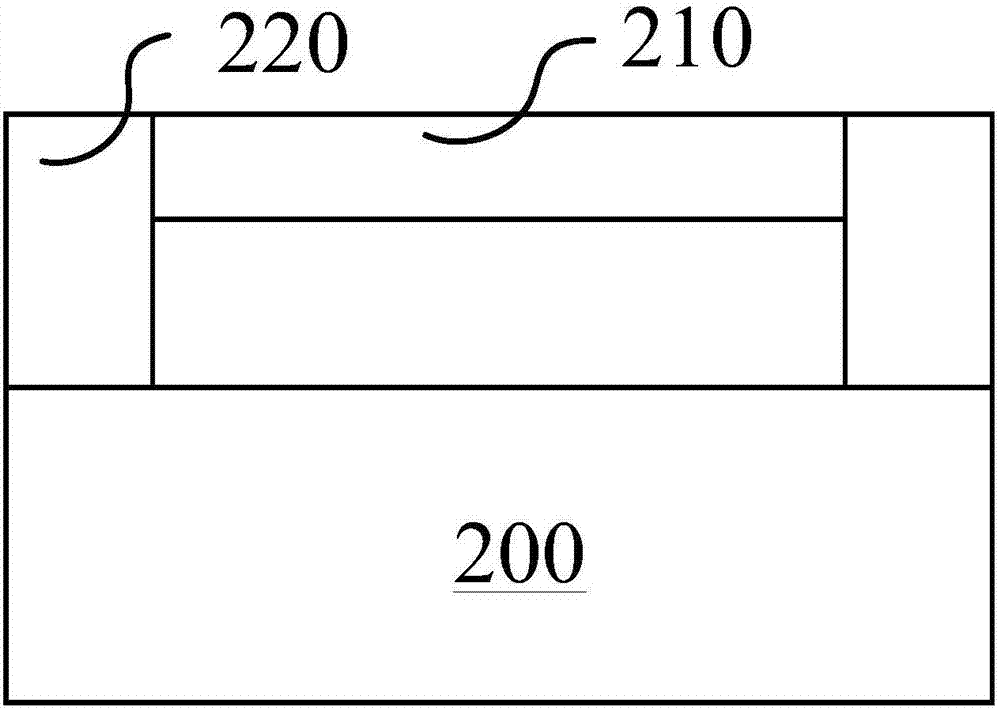

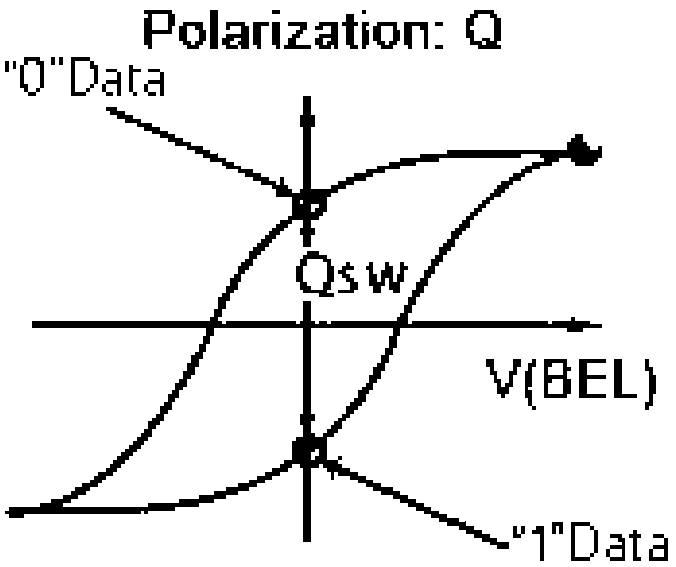

Non-volatile ferroelectric random access memory and preparation process thereof

ActiveCN108550576ASimple processSimple integration processSolid-state devicesSemiconductor devicesFerroelectric capacitorCapacitance

The invention relates to a non-volatile ferroelectric random access memory and a preparation process thereof. Since the surface formed by through hole filling is not flat, the structure of the layer and the spatial design of a substrate layer are combined and a ferroelectric capacitor is integrated on metal far away from the through hole. On the one hand, the performance damage of the ferroelectric capacitor because of the unevenness near the surface of the through hole is avoided; and on the other hand, the high-density memory unit design is realized. The ferroelectric random access memory prepared by the process has advantages of high storage density, high compatibility with a CMOS process line and simple process flow; and no planarization process is needed before ferroelectric capacitorintegration.

Owner:XIANGTAN UNIV

Double-sided efficient heat dissipation airtight packaging structure and preparation method thereof

ActiveCN113327904AMeet electromagnetic compatibility requirementsSatisfy the airtightness of the package structureFixed microstructural devicesVolume/mass flow by thermal effectsElectrical connectionEngineering

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

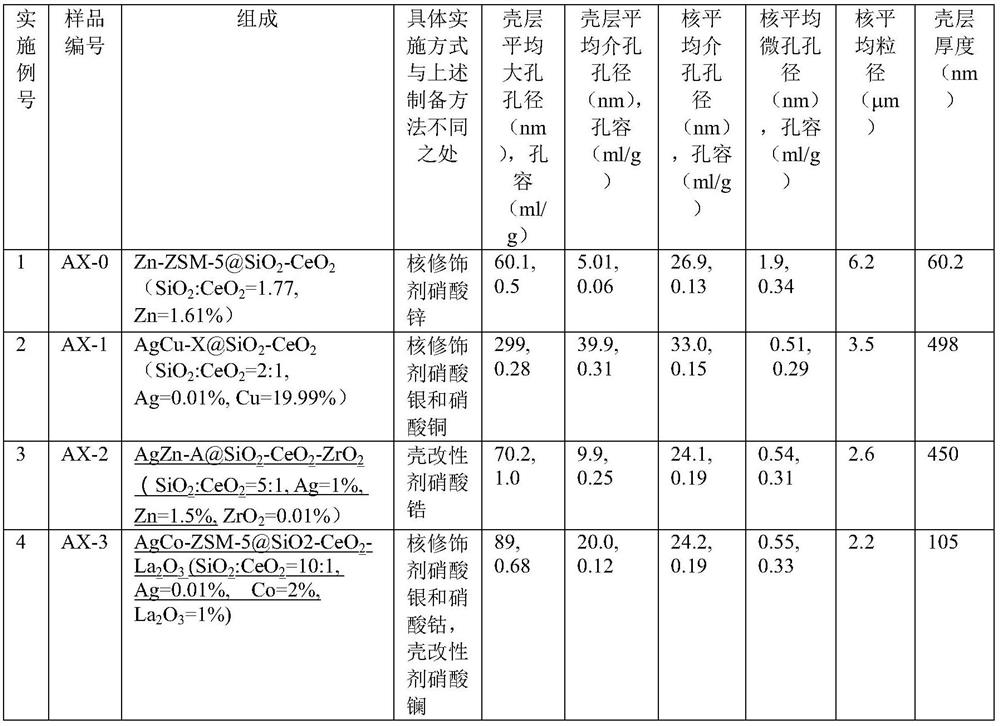

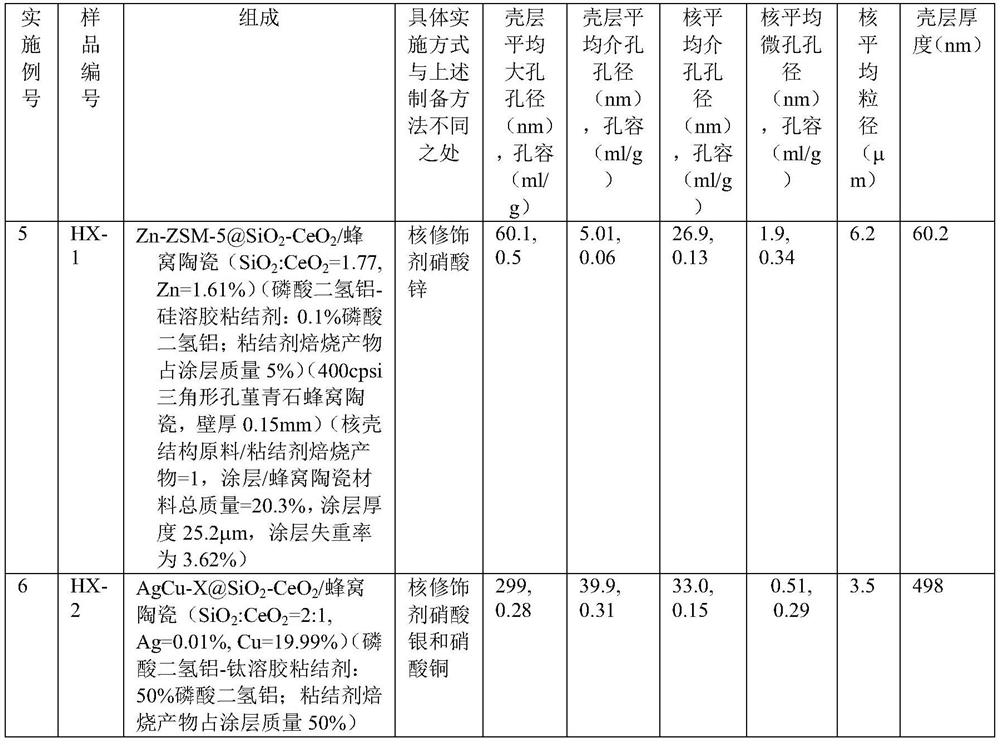

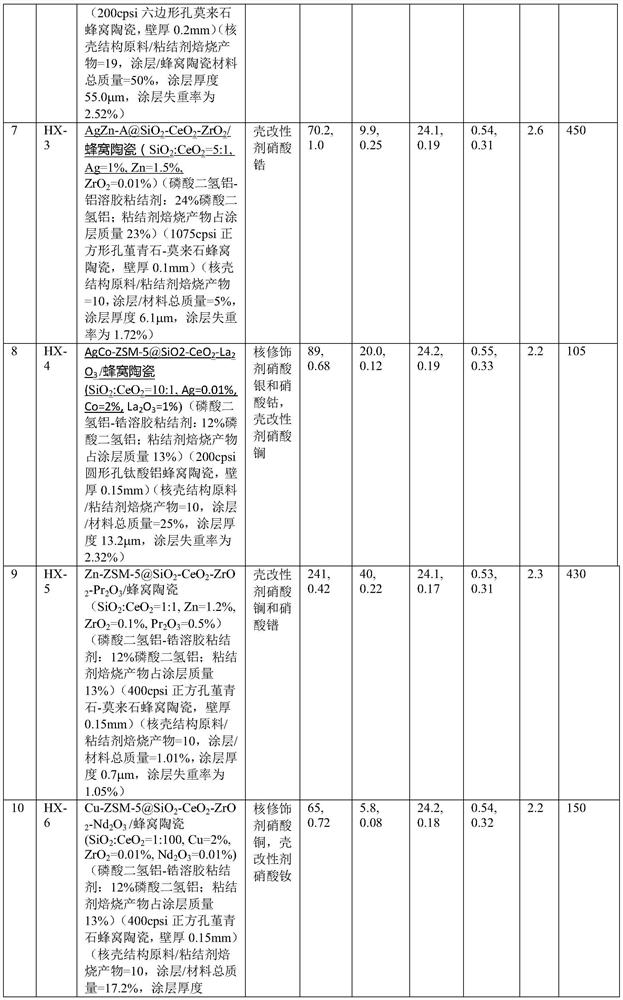

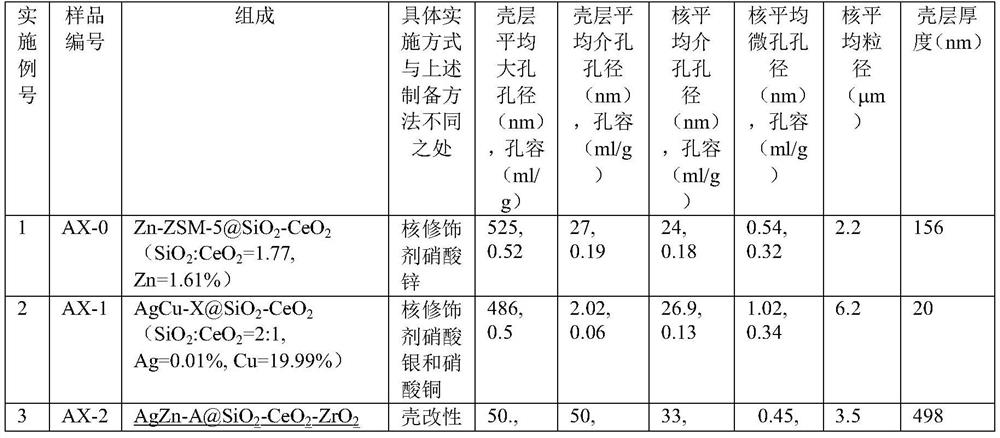

Honeycomb ceramic for adsorbing and inactivating viruses, and application thereof

ActiveCN113461440AAvoid churnSolve efficiency problemsGas treatmentDispersed particle separationMolecular sieveAir purifiers

The invention provides a honeycomb ceramic for adsorbing and inactivating viruses. The honeycomb ceramic is composed of a honeycomb ceramic matrix and a coating, the coating is composed of porous particles for adsorbing and inactivating viruses and a binder roasted product, each porous particle is composed of a shell and a core, and each shell is composed of oxygen storage materials SiO2-CeO2; and each core is a hierarchical pore molecular sieve. The honeycomb ceramic disclosed by the invention can be used for adsorbing and inactivating viruses, and further can be used as a filtering assembly to be used in the field of manufacturing of high-flow-speed air purification equipment such as air purifiers, air conditioners and fresh air systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

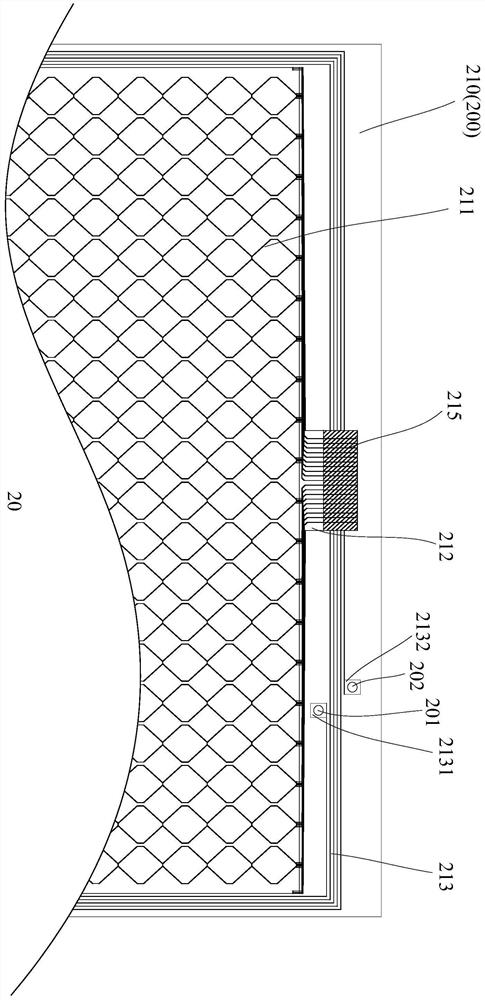

Display pronunciation integrated device and manufacturing method thereof

ActiveCN111710292ASimple integration processHigh-quality and more diverse sound effectsElectrical transducersStatic indicating devicesDisplay deviceHemt circuits

The invention provides a display pronunciation integrated device and a manufacturing method thereof, relates to the technical field of display and pronunciation integration, and aims at solving the problems that in the prior art, when a display device and a pronunciation device are integrated, the integration process is complex, and the pronunciation mode, quality and the like are limited. The manufacturing method comprises the steps: manufacturing the display pronunciation integrated device, manufacturing a driving back plate, forming a plurality of light-emitting elements on the driving backplate, distributing the plurality of light-emitting elements on the driving back plate in an array manner, forming gaps between the adjacent light-emitting elements, electrically connecting the plurality of light-emitting elements with the pixel driving circuits in a one-to-one correspondence manner, and enabling the light-emitting elements to emit light under the driving of the corresponding pixel driving circuits; and transferring a plurality of pronunciation devices into the gaps, so that the plurality of pronunciation devices are electrically connected with the pronunciation driving circuits in a one-to-one correspondence manner, and the pronunciation devices are used for pronunciating under the driving of the corresponding pronunciation driving circuits. The manufacturing method provided by the invention is used for manufacturing the display pronunciation integrated device.

Owner:BOE TECH GRP CO LTD

A kind of Glonass satellite orbit calculation method and system

ActiveCN105445766BSave resource callsSimple integration processSatellite radio beaconingSatellite orbitPositioning system

Owner:惠州市峰华经纬科技有限公司

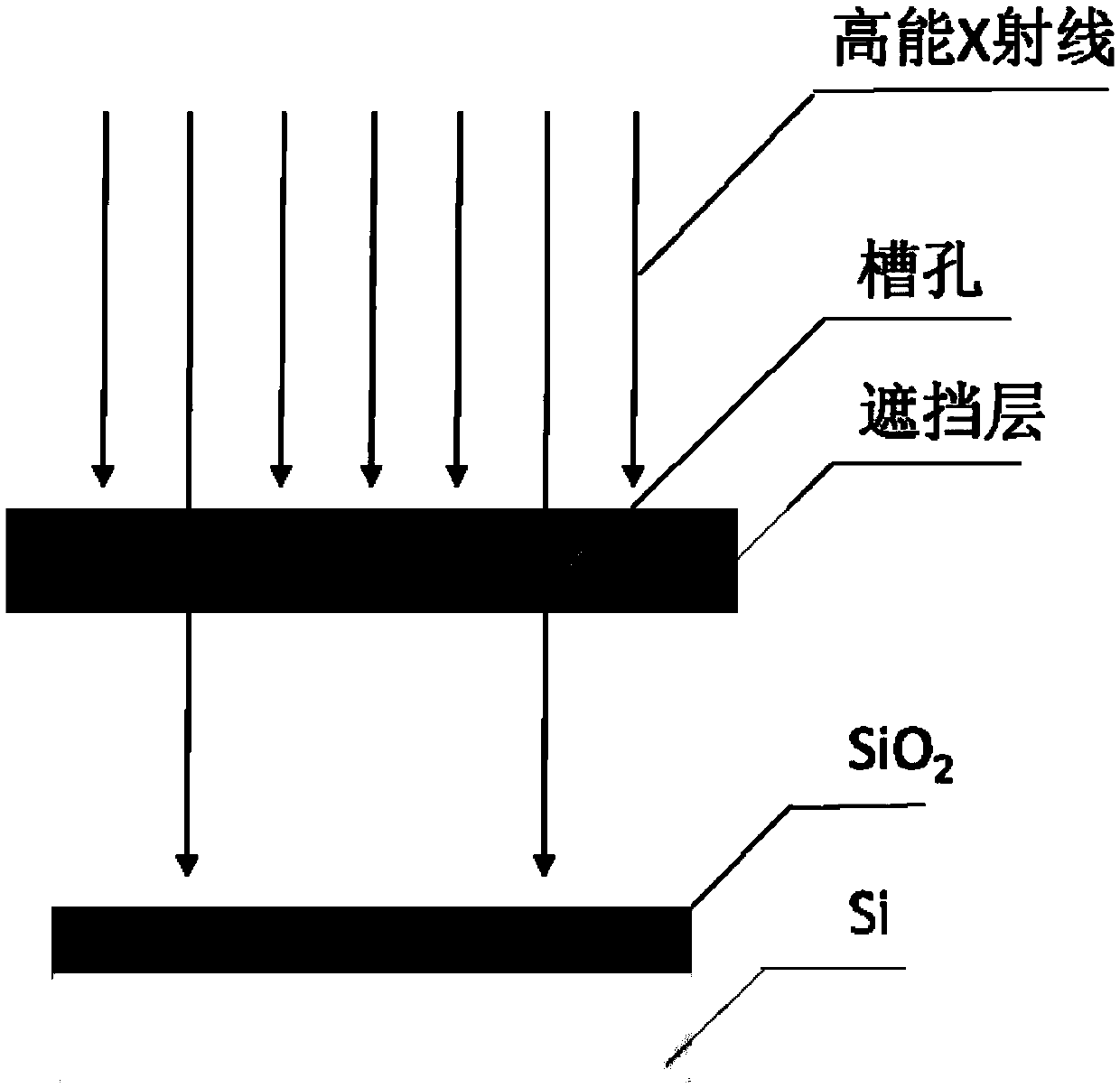

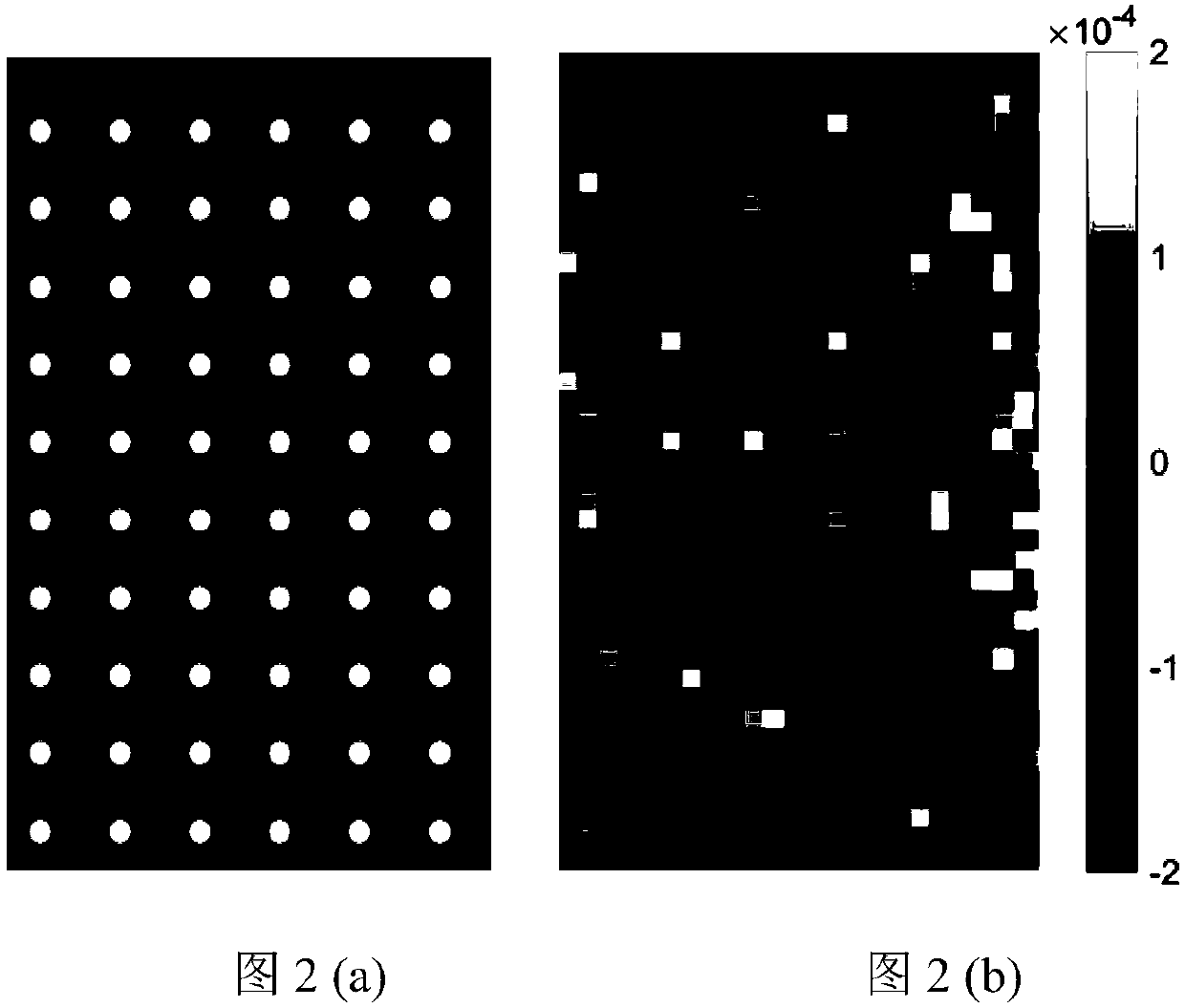

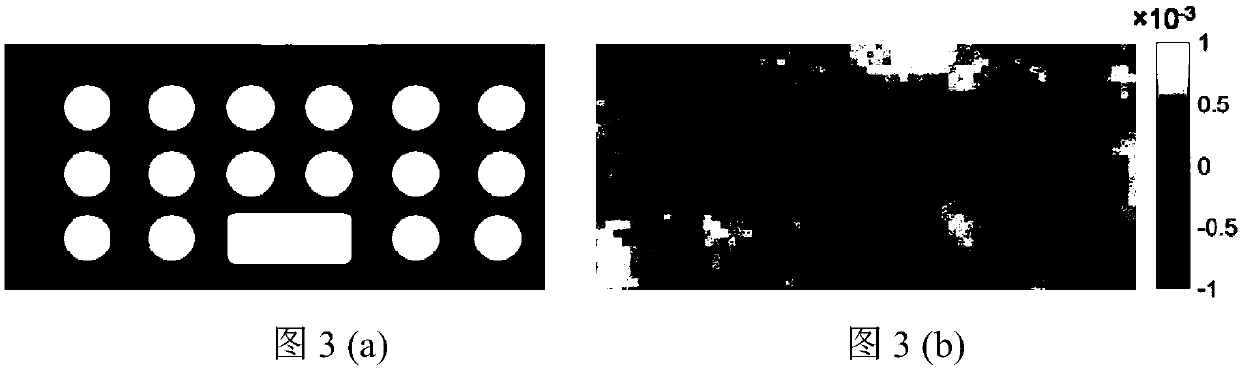

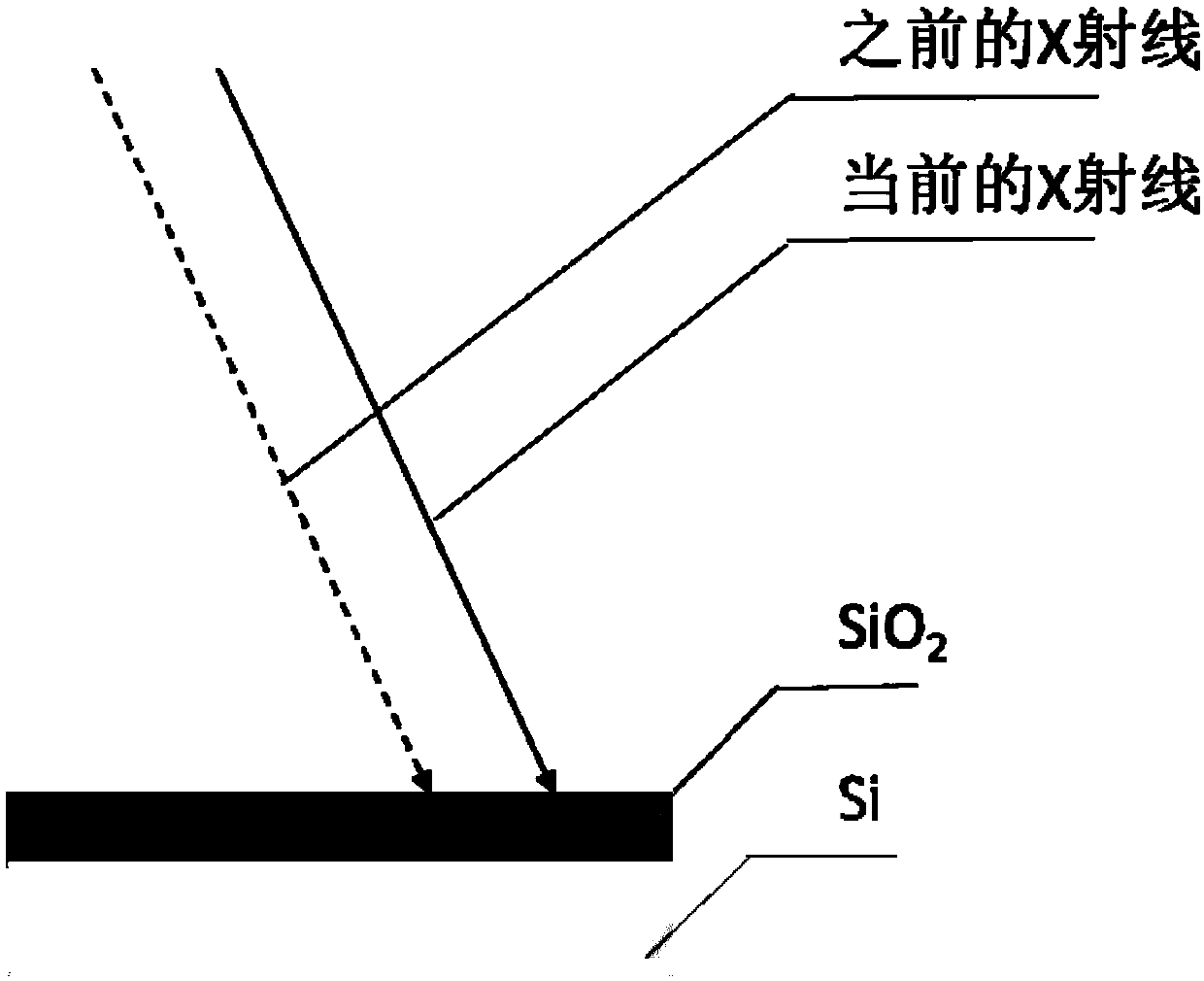

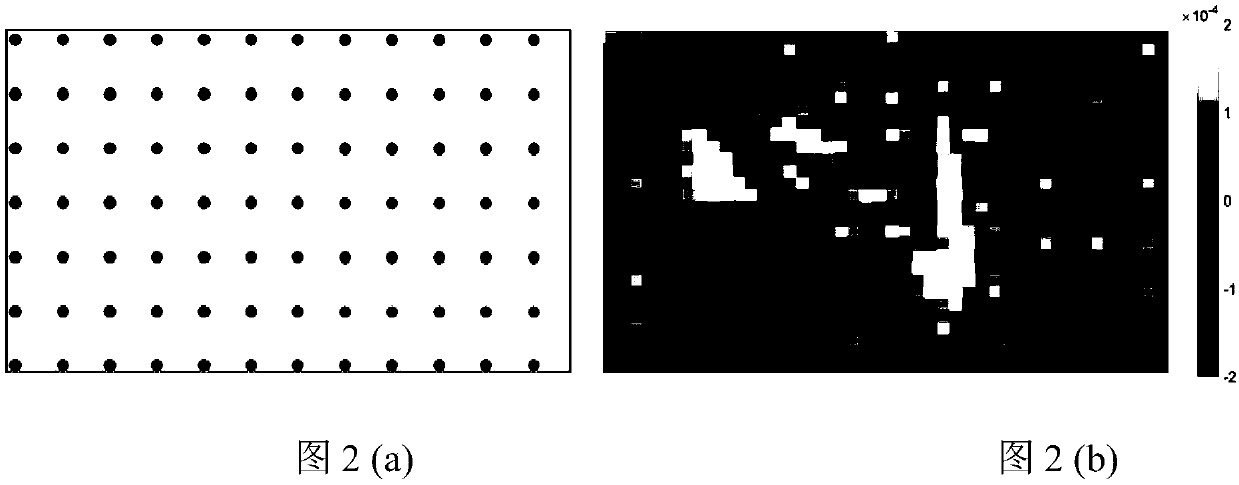

A method for preparing strained silicon by high-energy X-rays

ActiveCN108335973BImprove stabilityImprove reliabilitySemiconductor/solid-state device manufacturingMicro nanoHigh energy

The invention discloses a method for preparing strained silicon by high energy X ray, and relates to the manufacturing field of an integrated circuit. The method comprises the following steps of (1) synthesizing a Si / SiO<2> dual-layer composite structural system, wherein the upper surface of the structure is covered with a silicon thin film of a silicon dioxide layer; (2) if partial strain needs to occur, placing a shielding layer above the Si / SiO<2> dual-layer composite structural system, and forming a groove hole with the corresponding dimension and shape in the shielding layer above the required strain region of the silicon thin film; and if global strain needs to occur, not placing the shielding layer; and (3) performing illumination on the Si / SiO<2> dual-layer composite structural system by high energy X ray through the shielding layer to prepare strained silicon. By virtue of the initial application of the method of the high energy X ray, by combination of the method of region-selecting shielding, and by virtue of the characteristic that the X ray beam spot area is larger than the dimension of a silicon wafer, quick preparation of strained silicon is realized; and the methodhas the advantages of low working temperature, controllable strain region, no introduction of impurity, simple process, large scope of variables, high production efficiency, no silicon damage and thelike, and is expected to be widely applied to the fields of a semiconductor integrated circuit, a micro-nano electronic device and the like.

Owner:XI AN JIAOTONG UNIV

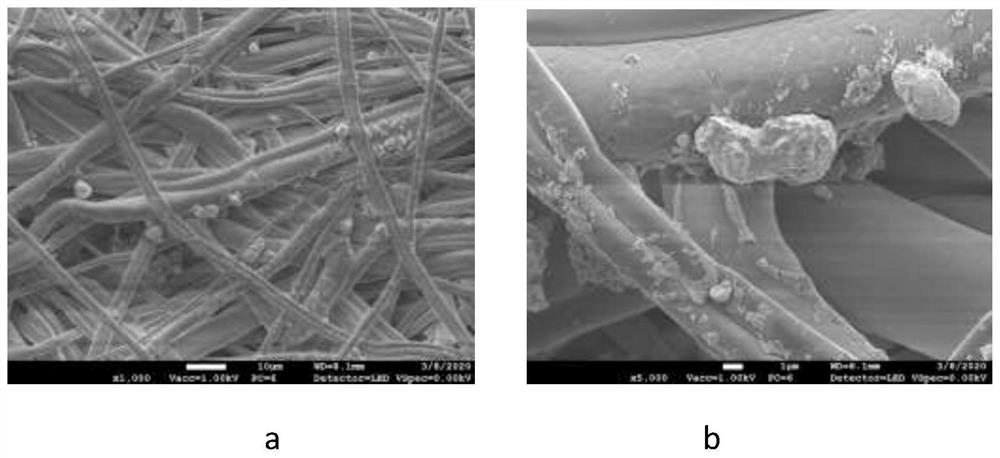

Melt-blown fabric for adsorbing and inactivating viruses and application

ActiveCN113463379AAvoid churnSolve the technical problem of short service lifeDispersed particle filtrationBiochemical fibre treatmentFiberMolecular sieve

The invention provides a melt-blown fabric for adsorbing and inactivating viruses. The melt-blown fabric is composed of a melt-blown fabric matrix and porous particles which are embedded on melt-blown fabric fibers and are used for adsorbing and inactivating the viruses, wherein each porous particle is composed of a shell and a core; each shell is composed of an oxygen storage material SiO2-CeO2; and each core is a hierarchical pore molecular sieve. The melt-blown fabric can be used for adsorbing and inactivating the viruses, can be used as a filtering assembly to be applied to wearing protection equipment such as masks and protective clothing and HEPA efficient filters, and can be further applied to equipment such as air purifiers, air conditioners and fresh air systems.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

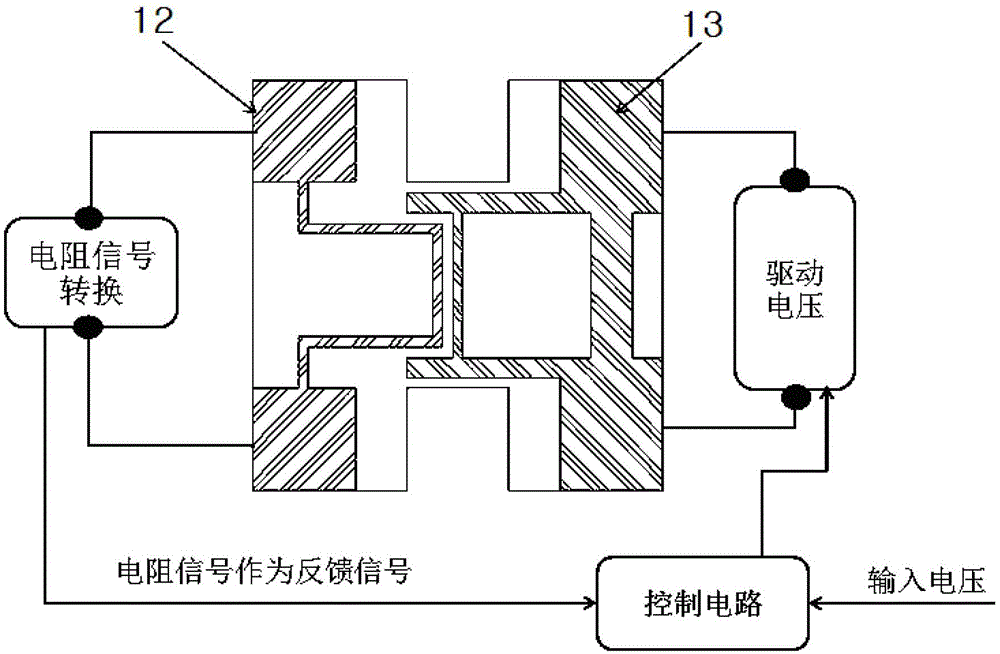

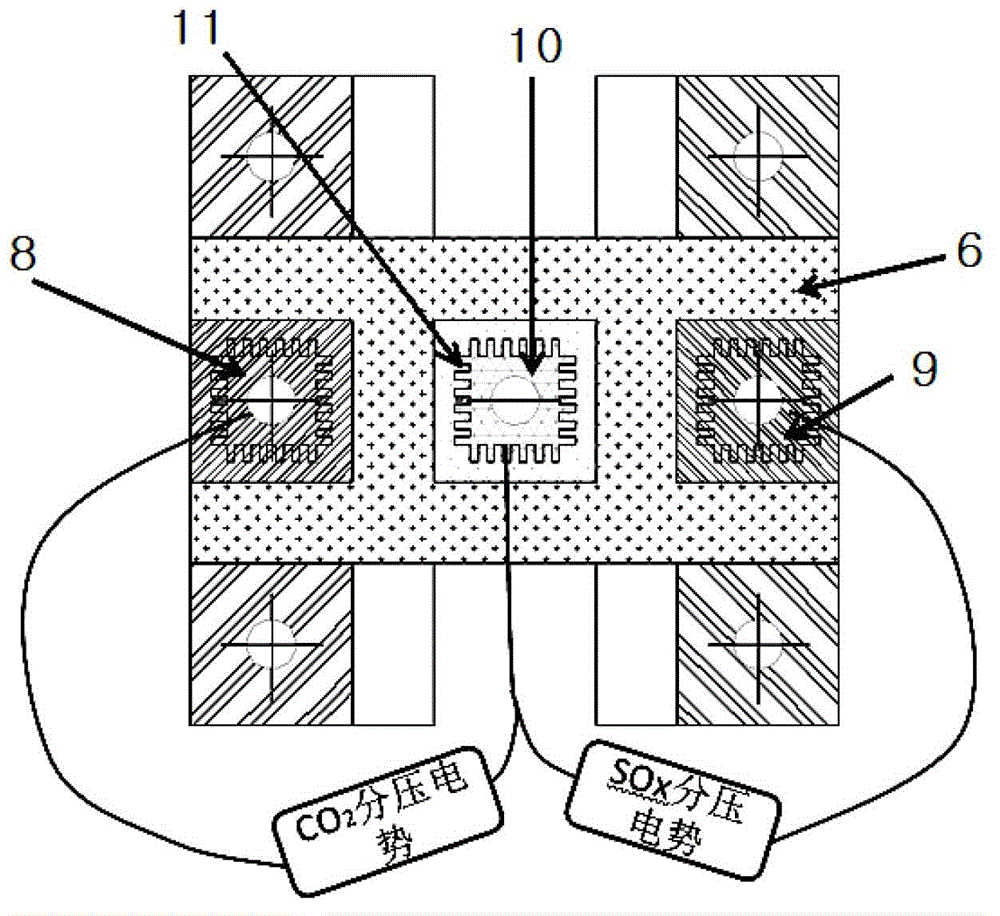

Common reference electrode temperature controlled CO2-SOx integrated gas sensor and preparation method thereof

ActiveCN102798651BReduce volumeReduce power consumptionMaterial electrochemical variablesElectrochemical responseTemperature control

The invention discloses a common reference electrode temperature controlled CO2-SOx integrated gas sensor and a preparation method thereof. The sensor comprises an alumina substrate, a heating element, a temperature measurement element, an insulating layer, a thin layer of solid electrolyte, an Au tooth-shaped film electrode, a CO2 reaction electrode, a SOx reaction electrode and a common reference electrode from the bottom up. The preparation method comprises the following steps: preparing a Pt or RuO2 heating and temperature measurement element on an Al2O3 substrate by a printing and sintering process; carrying out deposition process on a thick film micro-heating element to obtain the thin layer of solid electrolyte, an Au tooth-shaped electrode, the CO2 reaction electrode, the SOx reaction electrode and the common reference electrode, and forming a CO2-SOx gas-sensitive element combined with thin and thick-film technique by electrochemical reaction mode. According to the invention, a closed loop temperature-control system is formed by the feedback of the temperature measurement element, thus the temperature of the sensor reaches the temperature required by the work of each reaction electrode and keeps constant, and the optimum work performance of the CO2-SOx gas sensor is guaranteed.

Owner:SHENZHEN TIANDITONG ELECTRONICS CO LTD

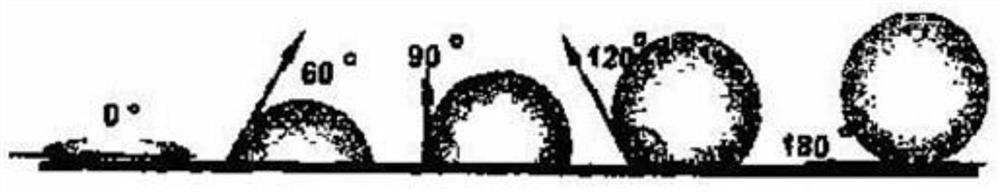

A method for forming an air gap

ActiveCN110190022BRaise the formation ratioAvoid depositionSemiconductor/solid-state device manufacturingSemiconductor devicesThermodynamicsThin membrane

The invention discloses a method for forming an air gap, which includes the following steps: S01: forming a groove between solid media; S02: preparing an insulating sheet-like two-dimensional material, wherein the insulating sheet-like two-dimensional material includes insulating Sheet-like layer, the size of the insulating sheet-like layer in the sheet-like two-dimensional direction is larger than the size of the above-mentioned groove; S03: deposit the insulating sheet-like two-dimensional material on the solid medium and the groove; S04: for the solid Annealing the dielectric and the insulating sheet-like two-dimensional material to form a stable thin film composed of the insulating sheet-like two-dimensional material on the groove. The method for forming an air gap provided by the present invention can effectively increase the formation ratio of the air gap, thereby greatly reducing the effective dielectric constant and interconnection delay, further reducing costs and improving product performance.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

A cmos device and its manufacturing method

ActiveCN107481971BThreshold adjustment association has little effectSimple integration processTransistorSemiconductor/solid-state device manufacturingCMOSOxygen plasma

The invention provides a CMOS device and a fabrication method thereof. The method comprises steps: a semiconductor substrate is provided; a first blocking layer is formed on the surface of the semiconductor substrate; hydrogen or oxygen plasma passivation processing is carried out on the first blocking layer on a second N channel area and a second P channel area; a first work function layer is formed on the first blocking layer on a first P channel area and the second P channel area; a second work function layer is formed on the first blocking layer on a first N channel area and the second N channel area and the first work function layer; and / or hydrogen or oxygen plasma passivation processing is carried out on the first blocking layer on the second N channel area and the first work function layer on the second P channel area. The method is high in threshold adjustment control precision, the process flexibility is high, and the method is simple and easy to operate and is more suitable for multi-threshold regulation on a small-size device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

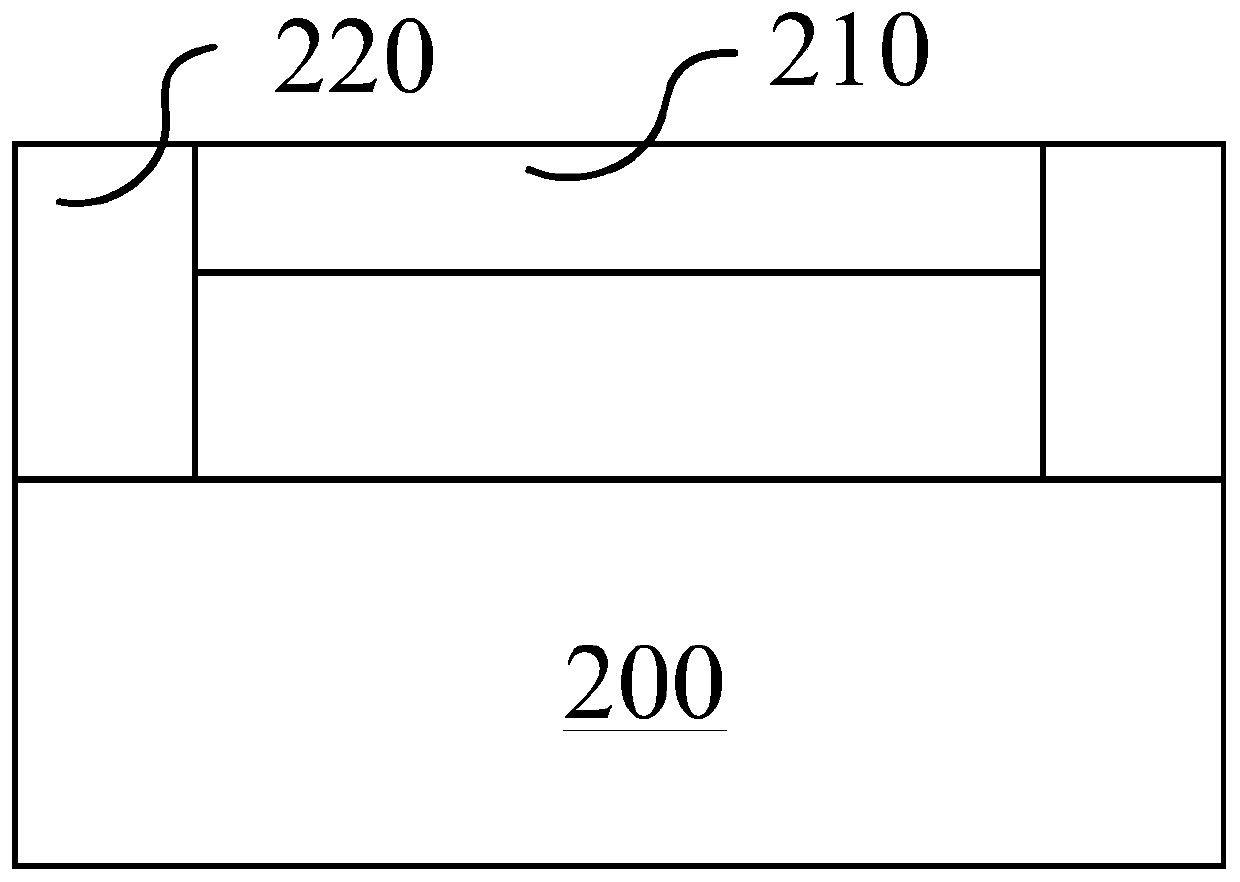

Integrated electro-optical modulator

PendingCN111240055ALow direct couplingLow Loss Direct CoupledOptical light guidesNon-linear opticsCoupling lossGrating

The invention discloses an integrated electro-optical modulator, comprising a SiO2 layer and a Si layer which are arranged in a stacked mode. A first silicon waveguide phase shift arm and a second silicon waveguide phase shift arm are arranged on the Si layer, and a PLC waveguide shunt and a combiner are arranged in the SiO2 layer. Two branches of the PLC waveguide splitter are respectively communicated with the first silicon waveguide phase shift arm light path and the second silicon waveguide phase shift arm light path based on evanescent wave coupling, and two branches of the PLC waveguidecombiner are respectively communicated with the first silicon waveguide phase shift arm light path and the second silicon waveguide phase shift arm light path based on evanescent wave coupling. The invention discloses an integrated electro-optical modulator. The PLC waveguide splitter / combiner is matched with the silicon waveguide phase shift arm to realize electro-optical modulation, so that high-speed electro-optical modulation is realized by utilizing the silicon waveguide phase shift arm, and low-loss direct coupling of the modulator and the optical fiber is realized by utilizing the characteristic that the PLC waveguide device is matched with a single-mode optical fiber mode field. The problems that according to traditional silicon-based electro-optical modulation, due to the fact that mismatch between a silicon waveguide and a single-mode optical fiber mode field is large, a mode spot converter or a vertical coupling grating of a complex structure needs to be arranged to achieveoptical fiber coupling, and coupling loss is large are solved.

Owner:HENGTONG ROCKLEY TECHNOLOGY CO LTD

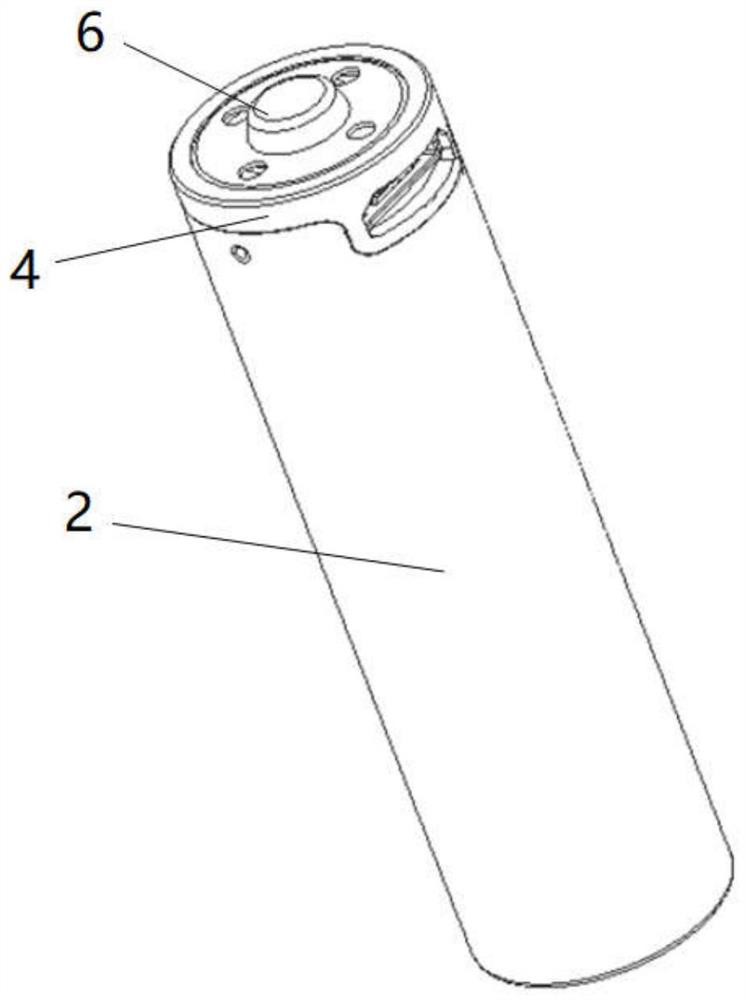

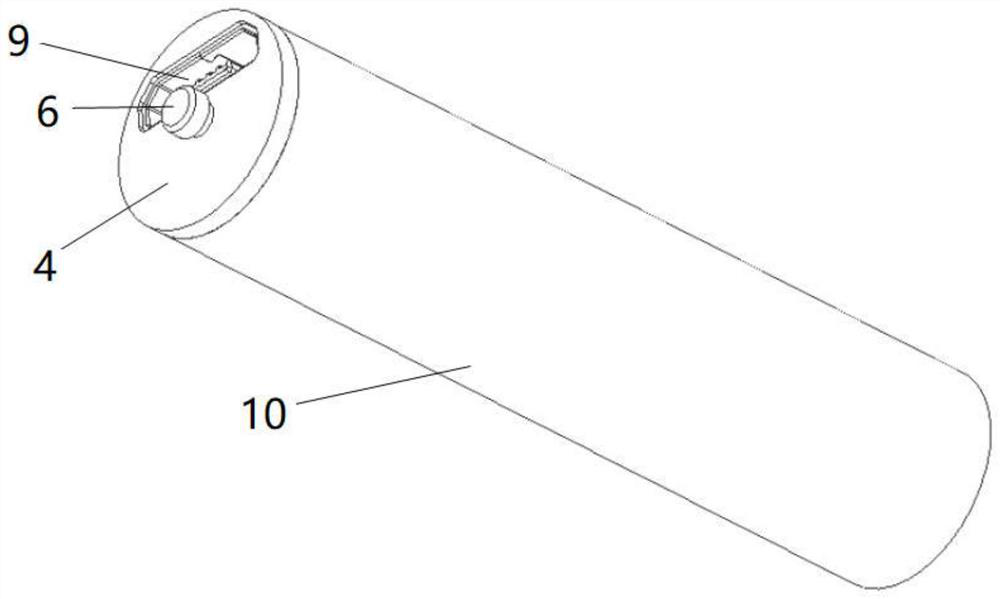

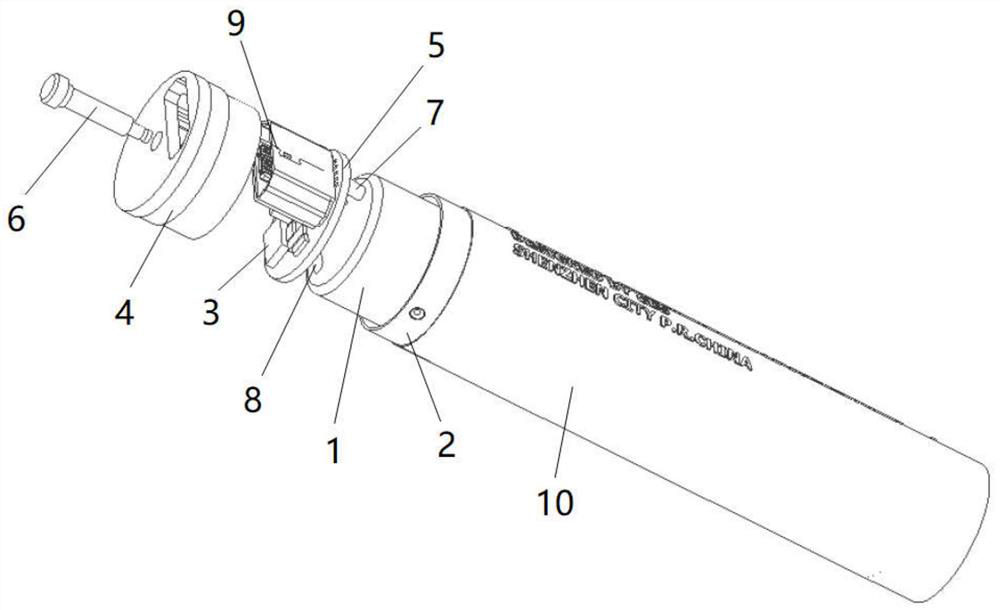

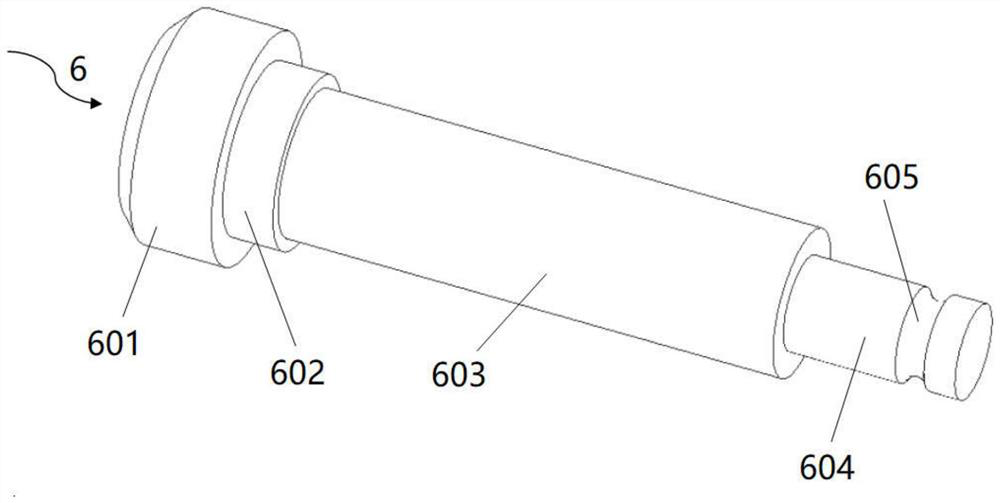

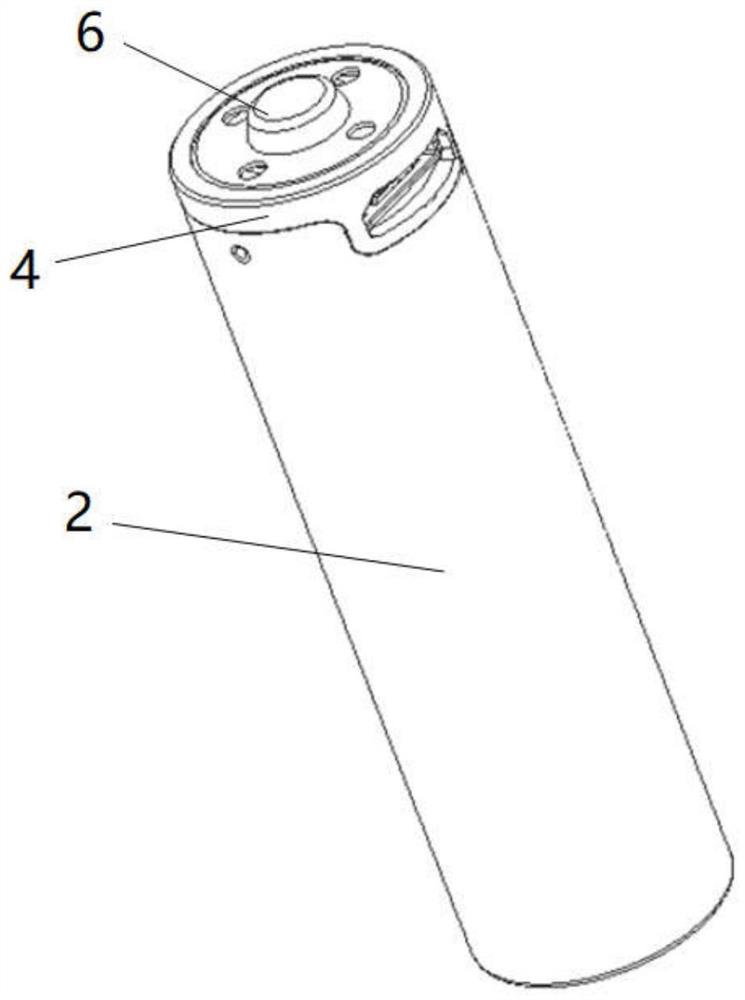

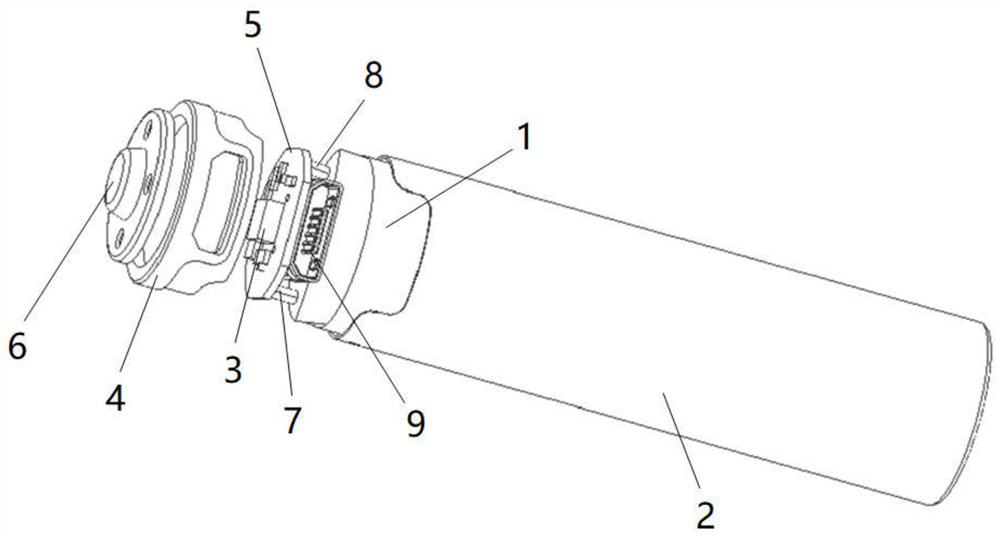

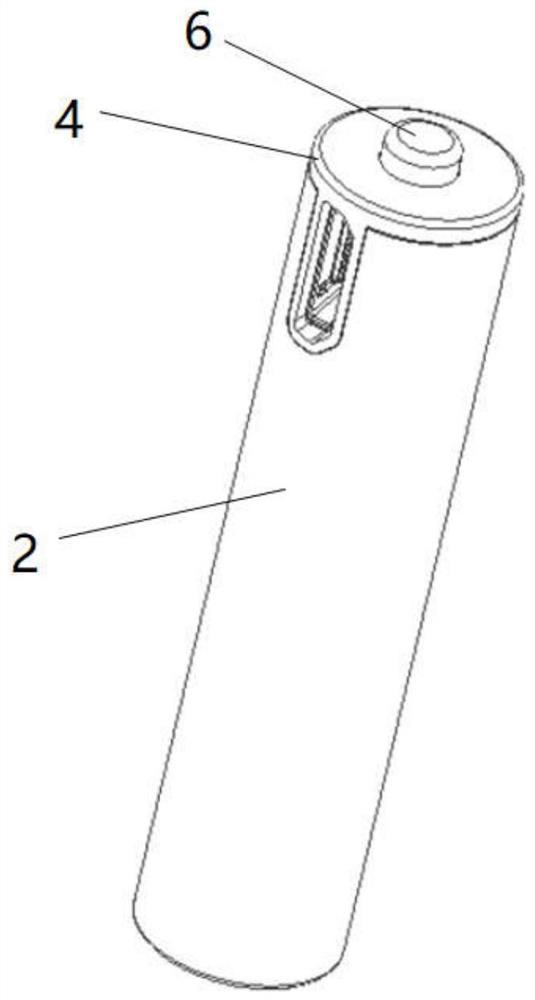

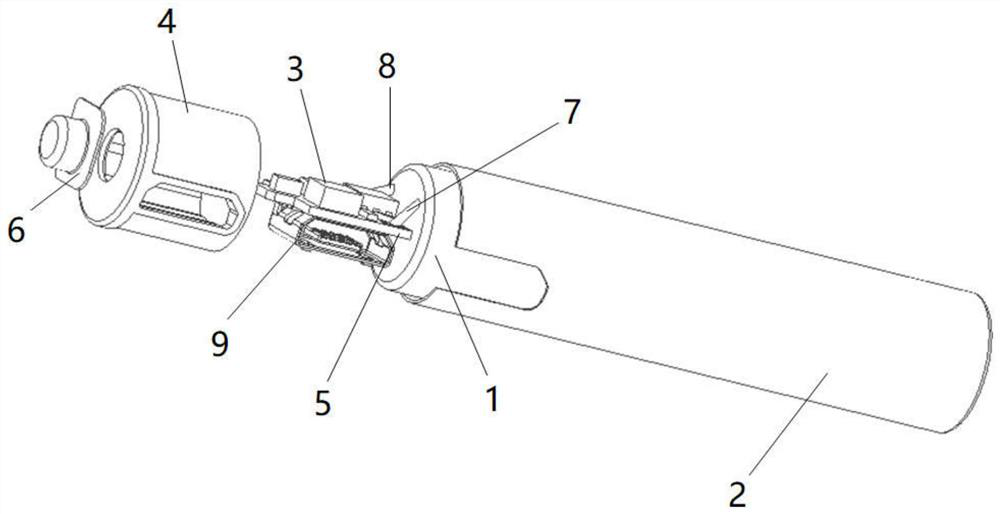

Lithium ion secondary battery

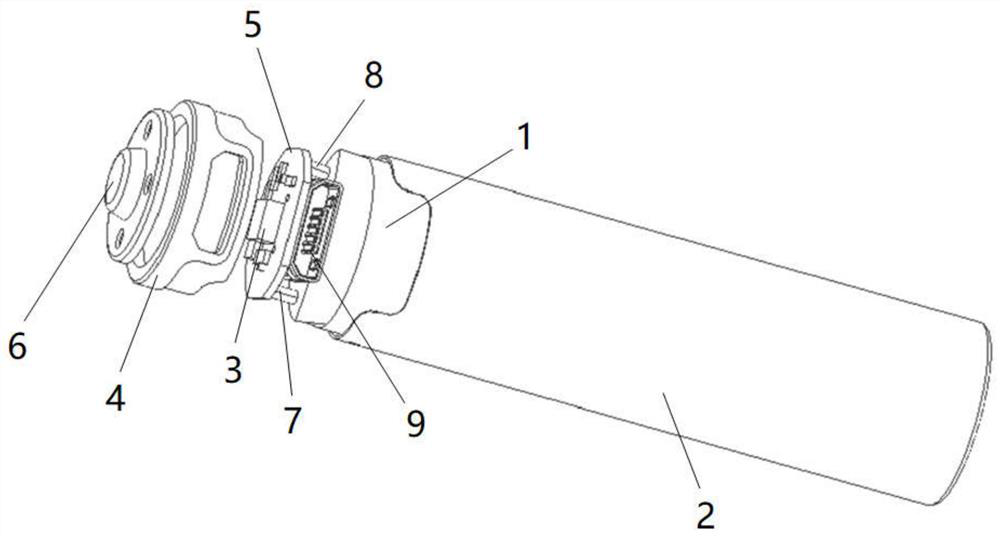

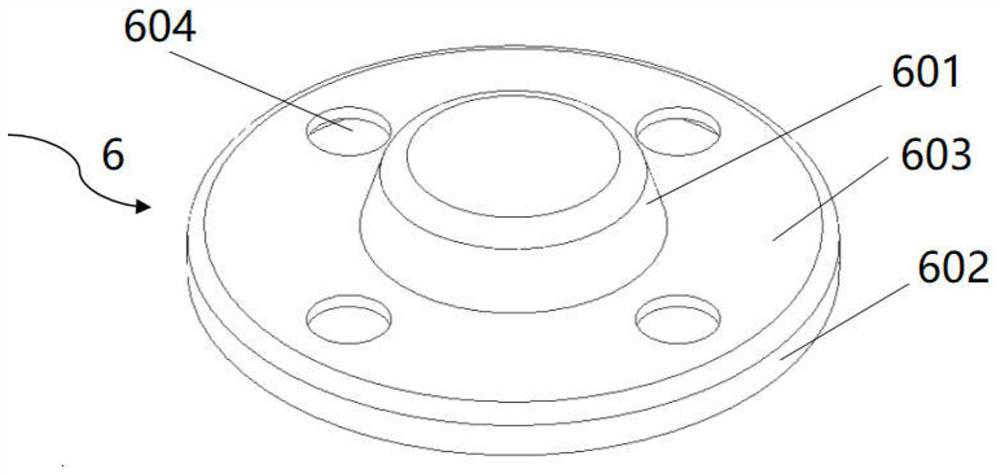

ActiveCN111740048ASimple integration processSimplified operational requirementsCells structural combinationCell component detailsElectric capacityLithium-ion battery

The invention provides a lithium ion secondary battery. The lithium ion secondary battery comprises a flexible package lithium ion battery cell, a steel shell, a MicroUSB interface, a protection IC, an integrated IC, a first resistor, a second resistor, a third resistor, a first capacitor, a second capacitor, a third capacitor, an inductor, an LED lamp, a plastic part, a hard FR-4 substrate and ametal cap, and the multiple integrated functions of charging, constant voltage output, charging management and protection and over-charging, over-discharging and over-current protection of the MicroUSB interface are realized. Compared with the prior art, the lithium ion secondary battery has the characteristics of high capacity and easiness in assembly.

Owner:NAT ENG RES CENT OF ADVANCED ENERGY STORAGE MATERIALS SHEN ZHEN LTD CO

A scanning high-energy micro-beam x-ray method for preparing strained silicon

ActiveCN108281353BNo damageShort exposure timeSemiconductor/solid-state device manufacturingMicro nanoHigh energy

The invention discloses a method for preparing strained silicon by a scanning-type high-energy microbeam X-ray, and relates to the field of the integrated circuit manufacture. The method comprises thefollowing steps: synthesizing a Si / SiO2 double-layer composite structure system, wherein the structure thereof is a silicon film of which the upper surface is covered by a silicon dioxide layer, successively illuminating areas expected to produce strain in the Si / SiO2 double-layer composite structure system by using the high-energy microbeam X-ray according to a certain sequence, to prepare the strained silicon of the local strain. The method is capable of firstly using a high-energy microbeam X-ray method, using a feature that the area of a beam spot of the microbeam X-ray is tiny, thereby achieving the purposes of accurately selecting and controlling the strain areas of the strained silicon, and producing the size-controllable strain capacity in the different strain areas. The method has the advantages of controllable strain areas and size precision, low working temperature, no introduced impurities, simple process, large strain capacity range, no damage to silicon and the like, andis expected to be extensively applied in the fields, such as semiconductor integrated circuits and micro-nano electronic devices.

Owner:XI AN JIAOTONG UNIV

Integrated manufacturing method for mems thin-film capacitive multi-parameter sensors

ActiveCN102798403BReduce volumeLow costDecorative surface effectsSolid-state devicesCapacitanceEngineering

The invention discloses an MEMS (Micro Electro Mechanical System) film capacitive type multi-parameter sensor structure and an integrated manufacturing method thereof. An MEMS carrying substrate is provided with MEMS film capacitive type pressure, temperature and humidity sensors which are arranged side by side. Electrodes, sacrificial layers, sensitive layers, sensitive films and protective layers of the three sensors adopt mutually matching structures and materials and therefore can be manufactured through an integrated surface micro-processing technology. The multi-parameter sensor structure and the integrated manufacturing method provided by the invention have the advantages of reducing volume of components, simplifying technical steps and being capable of decreasing cost of sensor products to a certain extent. In addition, the wholly capacitive structure adds application potential of the MEMS film capacitive type multi-parameter sensor structure in an inductive coupling based passive wireless sensing system.

Owner:中科芯未来微电子科技成都有限公司

Lithium-ion secondary battery

ActiveCN111463374BSimplified operating process requirementsEasy to operateSmall-sized cells cases/jacketsCells structural combinationElectric capacityPhysical chemistry

The invention provides a lithium ion secondary battery, which includes a lithium ion cell, a first resistor, a second resistor, a third resistor, a first capacitor, a second capacitor, a third capacitor, a label, a steel case, and a MicroUSB interface. , protection IC, integrated IC, inductor, LED light, plastic parts, rigid FR‑4 substrate and metal cap. The MicroUSB interface is set on the positive end of the battery to realize MicroUSB interface rechargeability, constant voltage output, charging management and protection, over-voltage protection, etc. Multiple functions of charge, over-discharge and over-current protection. Compared with the existing technology, the lithium ion secondary battery of the present invention has a simple process and is easy to install, has high integration efficiency, high reliability, higher capacity and lower cost.

Owner:NAT ENG RES CENT OF ADVANCED ENERGY STORAGE MATERIALS SHEN ZHEN LTD CO

A kind of cmos device and manufacturing method thereof

ActiveCN107464783BThreshold adjustment association has little effectSimple integration processTransistorSolid-state devicesCMOSEngineering

The invention provides a CMOS device and a manufacturing method thereof. The manufacturing method comprises the following steps: providing a semiconductor substrate; forming first blocking layers on the surface of the semiconductor substrate; performing plasma nitriding treatment on the first blocking layers of a second N channel area and a second P channel area; forming a first work function layer on the first blocking layers of a first P channel are and the second P channel area; forming second work function layers on the first blocking layers of a first N channel area and the second N channel area as well as the first work function layer; and / or performing plasma nitriding treatment on the first blocking layer on the second N channel area and the first work function layer on the second P channel area. The method is high in control precision of adjusting threshold value; furthermore, the process is high in flexibility, simple and practical, and the method is suitable for regulation and control of multiple threshold values of small-size devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Lithium-ion secondary battery

ActiveCN111740048BSimple integration processSimplified operational requirementsCurrent conducting connectionsCells structural combinationCapacitanceEngineering

The invention provides a lithium-ion secondary battery, including a soft-packed lithium-ion cell, a steel case, a MicroUSB interface, a protection IC, an integrated IC, a first resistor, a second resistor, a third resistor, a first capacitor, and a second capacitor , the third capacitor, inductor, LED light, plastic parts, rigid FR‑4 substrate and metal cap, realize the multi-in-one function of MicroUSB interface rechargeable, constant voltage output, charging management and protection, overcharge, overdischarge and overcurrent protection. Compared with the prior art, the lithium ion secondary battery of the present invention has the characteristics of high capacity and easy assembly.

Owner:NAT ENG RES CENT OF ADVANCED ENERGY STORAGE MATERIALS SHEN ZHEN LTD CO

A kind of cmos device and manufacturing method thereof

ActiveCN107564864BThreshold adjustment association has little effectSimple integration processTransistorSemiconductor/solid-state device manufacturingCMOSComputational physics

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

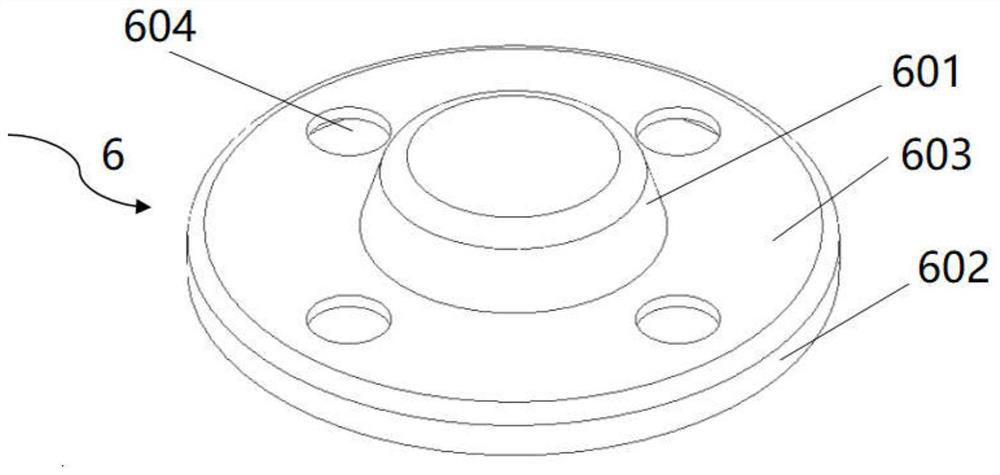

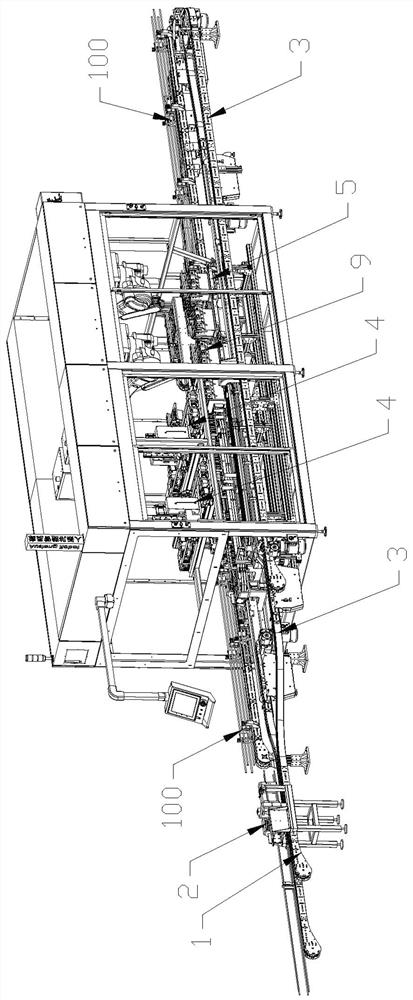

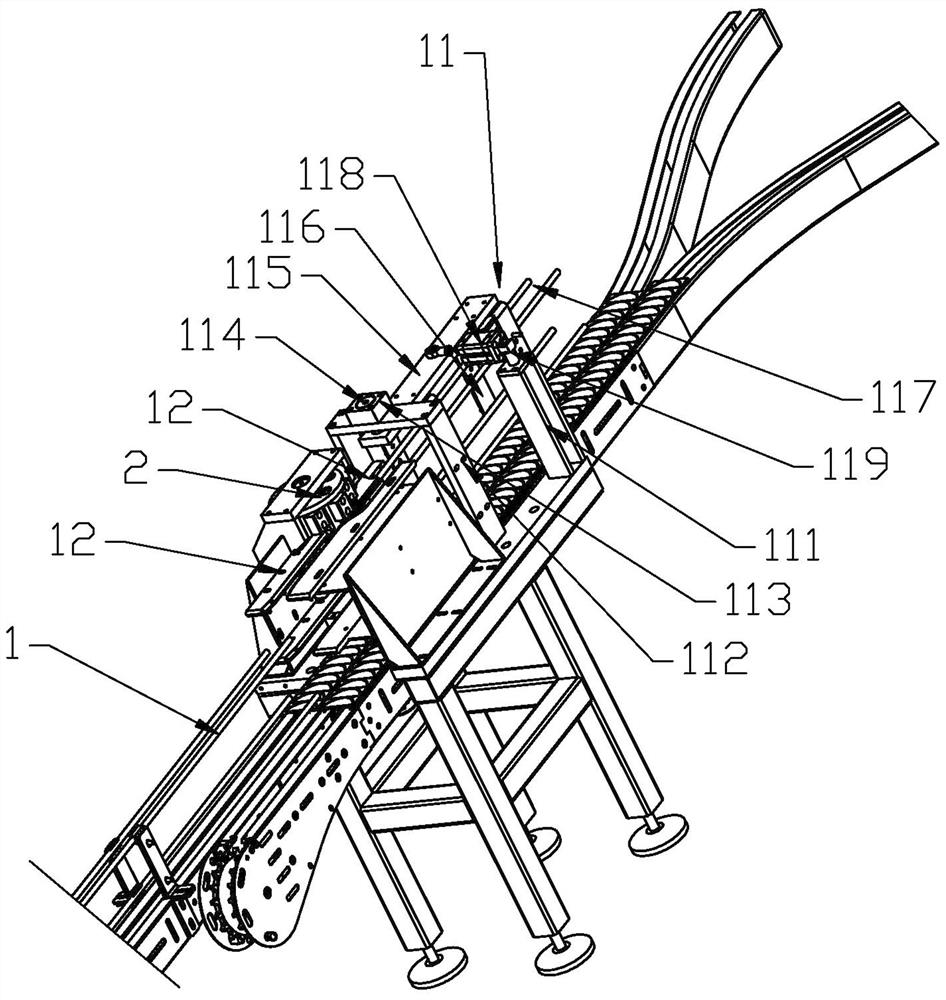

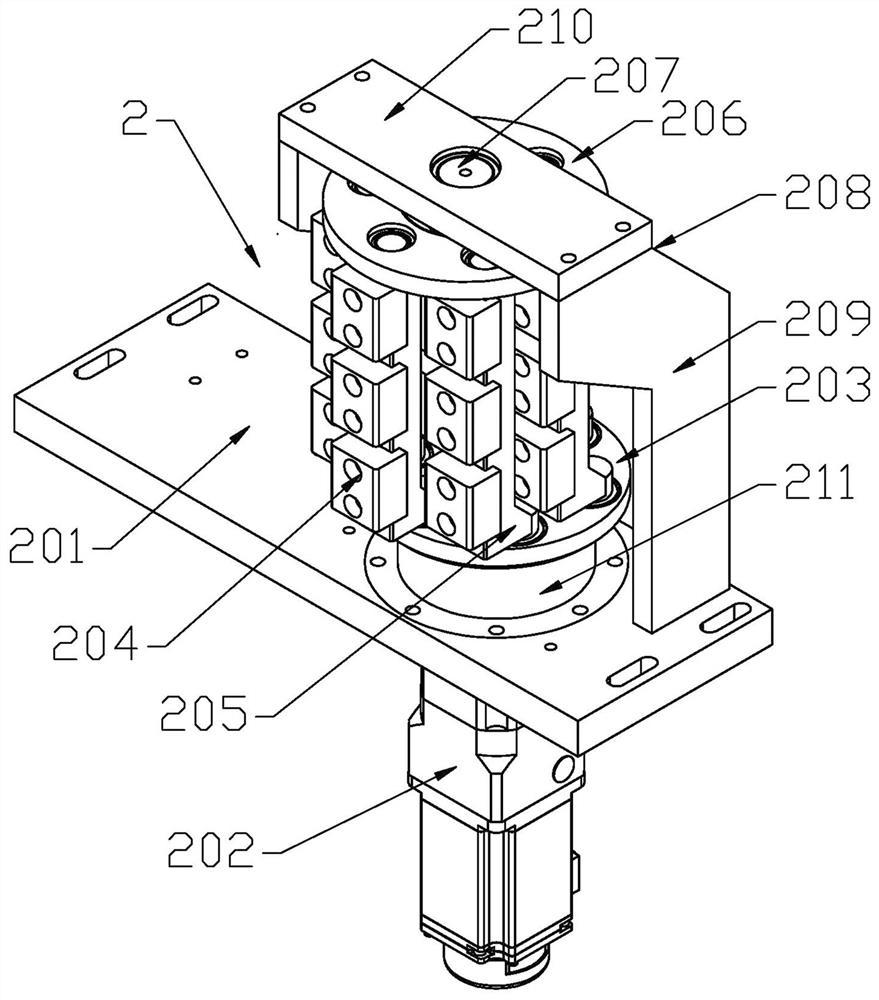

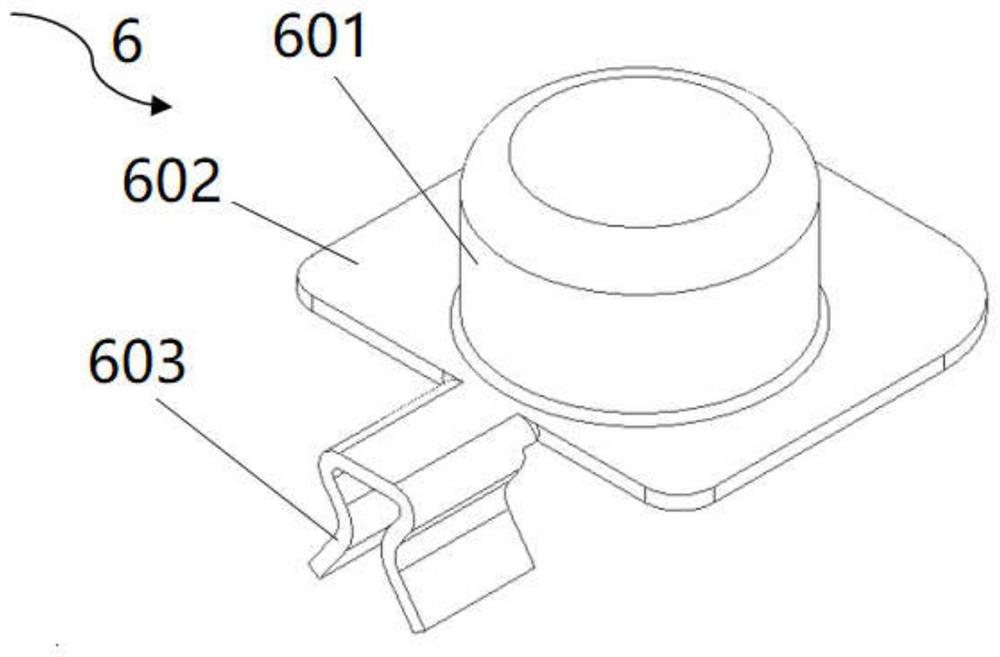

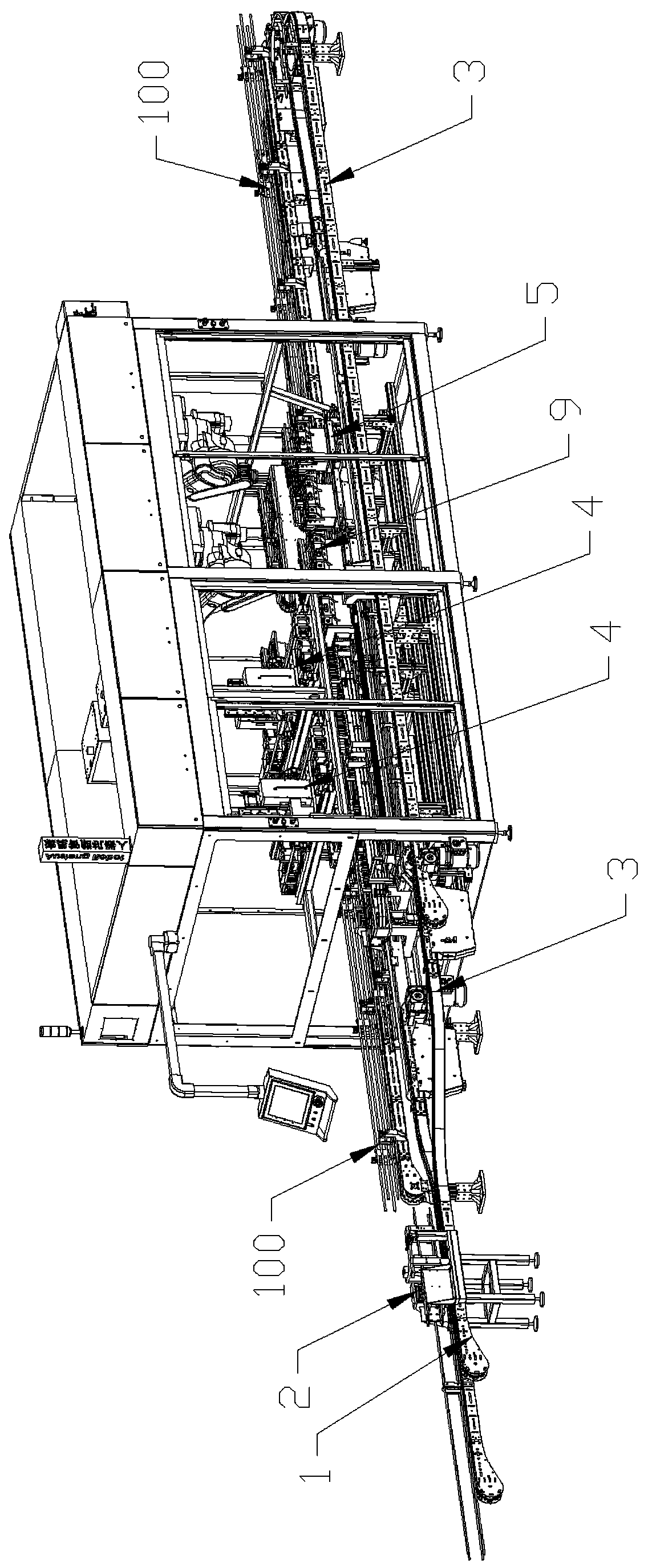

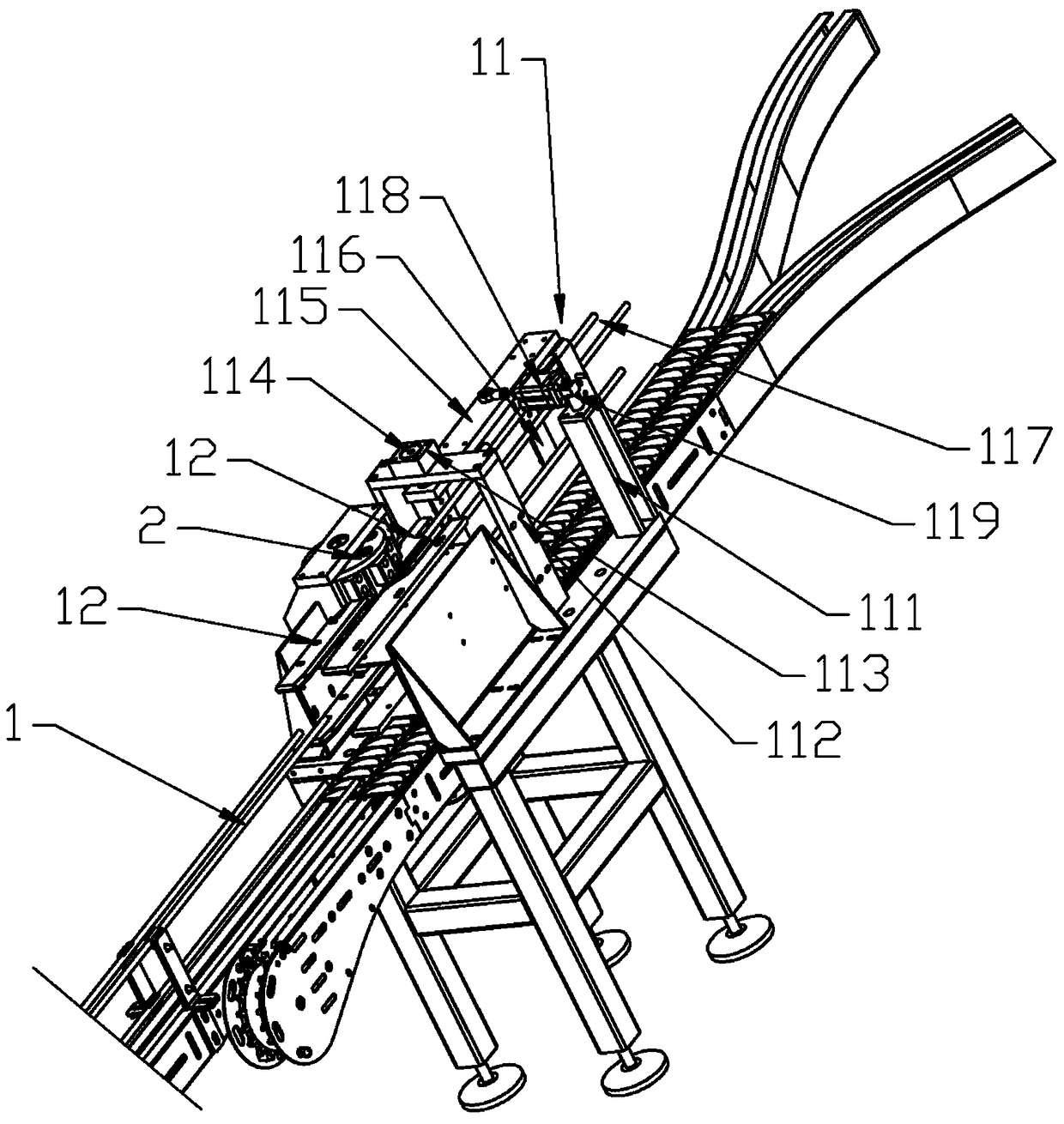

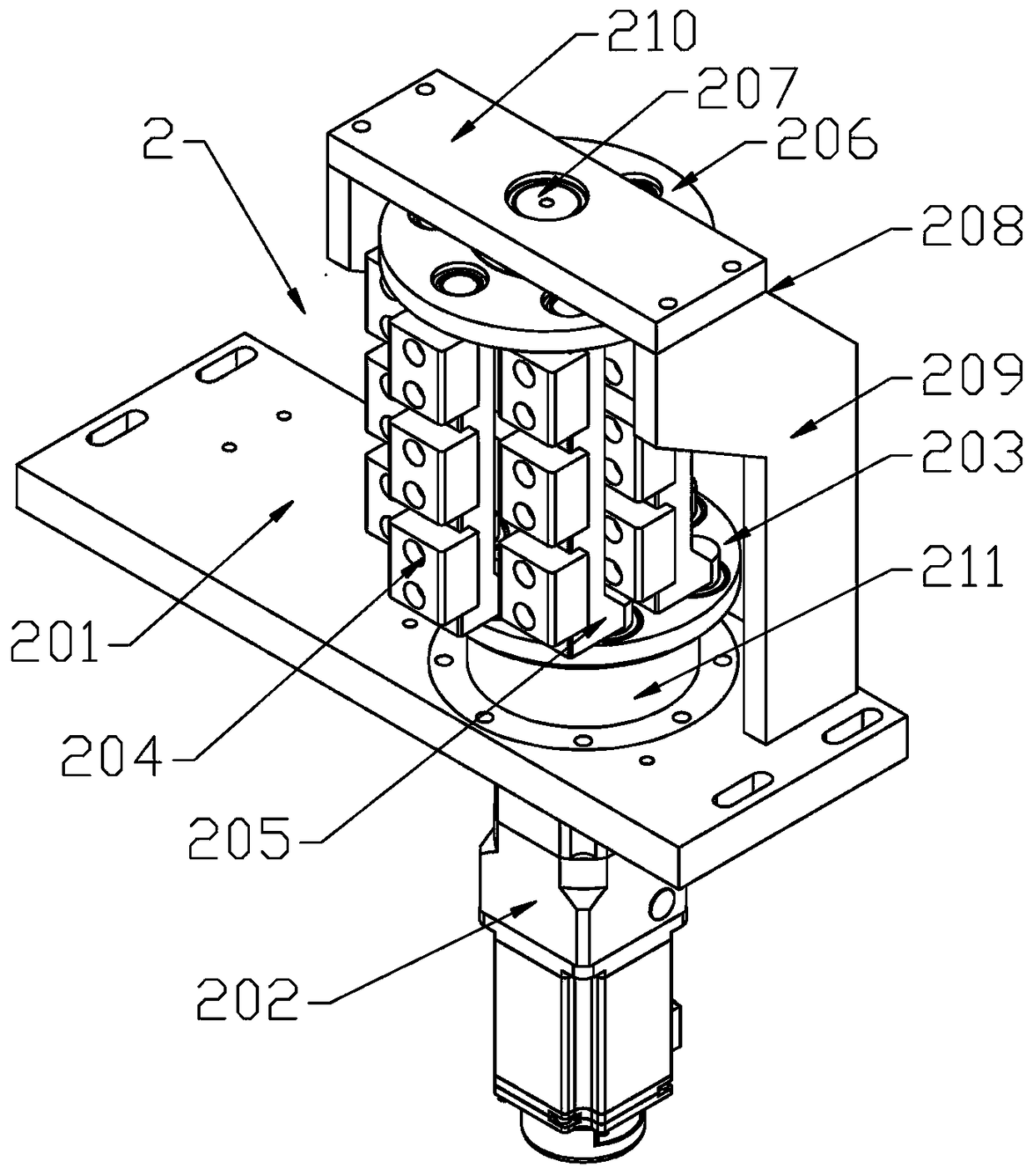

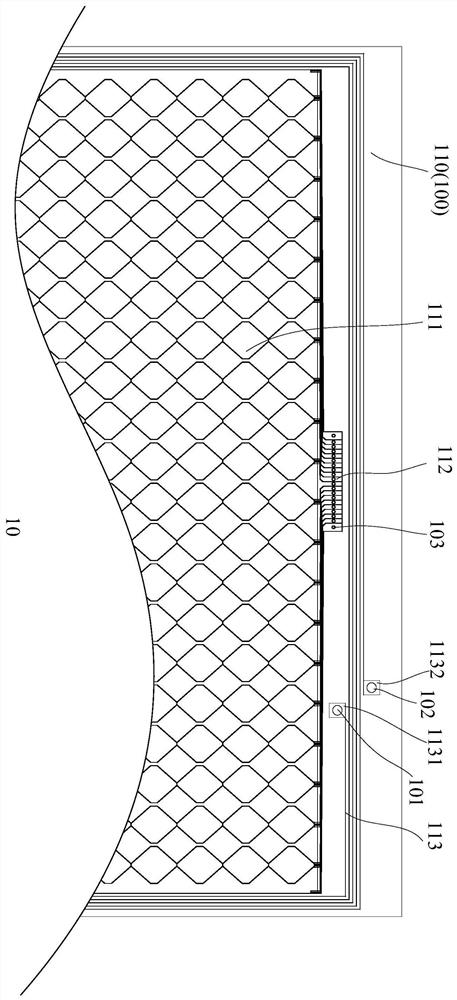

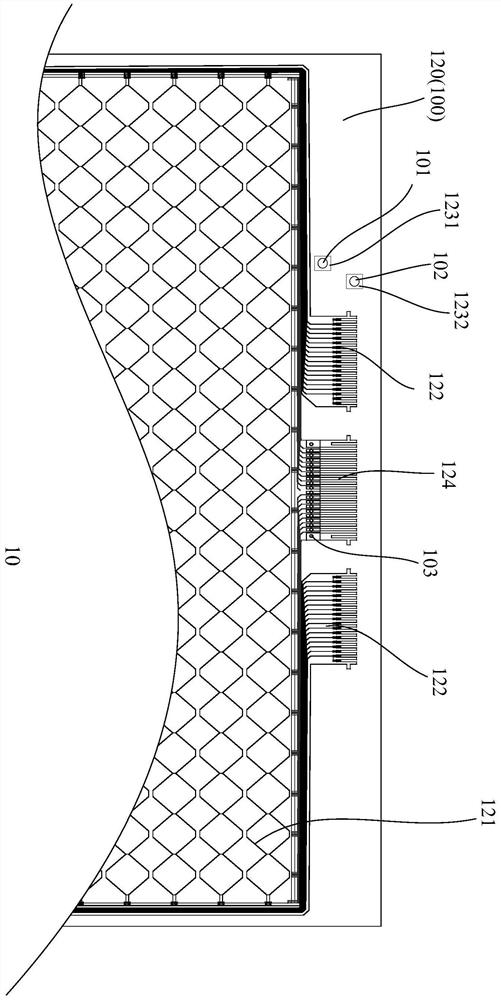

Packing machine

ActiveCN109335086BPrecise positioningSimple integration processPackaging automatic controlEngineeringMachine

The invention discloses a case packing machine, which comprises a milk bag conveying line (1), on which a bag divider (2) is arranged and on the rear side of the bag divider (2) a divider channel mechanism (11), the rear end of the milk bag conveying line (1) is respectively connected to the front end of the corresponding pre-integrated conveying line (3) with the bag divider (2), and the rear end of the bag divider (2) On the top of the pre-integrated conveying line (3) there is a single-side bag-grabbing conveying device (4), and on the side of the pre-integrated conveying line (3) there is an integrated conveying line (5) and a packing case conveying line (100 ), a packing platform (7) is embedded between the packing box conveying lines (100), and a packing box positioning and conveying device (6) is provided in front of the packing platform (7) and on the packing platform ( 7) is provided with a flexible fixture (9) fixed at the front end of the mechanical arm of the robot. The integration process of the invention is simple and can realize the precise positioning of the packing box.

Owner:苏州澳昆智能机器人技术有限公司

Display and pronunciation integrated device and its manufacturing method

ActiveCN111710292BSimple integration processHigh-quality and more diverse sound effectsElectrical transducersStatic indicating devicesDisplay deviceHemt circuits

The present invention provides a display and pronunciation integration device and a manufacturing method thereof, and relates to the technical field of display and pronunciation integration. In order to solve the problem of complex integration process and limitations in the way and quality of pronunciation when the display device and the pronunciation device are integrated in the prior art The problem. The manufacturing method of the display and pronunciation integrated device includes: making a driving backplane, forming a plurality of light-emitting elements on the driving backplane, the plurality of light-emitting elements are distributed on the driving backplane in an array, and there are gaps between adjacent light-emitting elements. Each light-emitting element is electrically connected to the pixel driving circuit in one-to-one correspondence, and the light-emitting element is used to emit light under the drive of the corresponding pixel driving circuit; a plurality of sound-emitting devices are transferred in the gap, so that the plurality of sound-emitting devices are in one-to-one correspondence with the sound-emitting driving circuit Electrically connected, the sounding device is used for sounding under the drive of the corresponding sounding driving circuit. The manufacturing method provided by the invention is used for manufacturing a display and pronunciation integrated device.

Owner:BOE TECH GRP CO LTD

Lithium-ion secondary battery

ActiveCN111463373BSimple integration processQuick assemblyBattery isolationCells structural combinationCapacitancePhysical chemistry

The invention provides a lithium-ion secondary battery, comprising a lithium-ion cell, a first resistor, a second resistor, a third resistor, a first capacitor, a second capacitor, a third capacitor, a fourth capacitor, a fifth capacitor, Steel shell, MicroUSB interface, protection IC, integrated IC, inductor, LED lamp, plastic parts, rigid FR‑4 substrate and metal cap, realize MicroUSB interface rechargeable, constant voltage output, charging management and protection, overcharge, overdischarge and overcurrent Protection of all-in-one functions. Compared with the prior art, the lithium ion secondary battery of the present invention has simple structure, easy installation, high integration efficiency, high reliability, multiple functions, high capacity and low cost.

Owner:NAT ENG RES CENT OF ADVANCED ENERGY STORAGE MATERIALS SHEN ZHEN LTD CO

Boxing machine

ActiveCN109335086APrecise positioningSimple integration processPackaging automatic controlCartoning machineMechanical engineering

The invention discloses a boxing machine. The boxing machine comprises a dairy bun conveying line (1), wherein the dairy bun conveying line (1) is provided with a dairy bun distribution device (2), the rear side of the dairy bun distribution device (2) is provided with a channel distribution mechanism (11), the rear end of the dairy bun conveying line (1) is connected with the front end of a corresponding pre-integrated conveying line (3) with the dairy bun distribution device (2), a single-side bun grabbing and conveying device (4) is arranged above the pre-integrated conveying line (3) on the rear side of the dairy bun distribution device (2), an integrated conveying line (5) and packaging box conveying lines (100) are arranged beside the pre-integrated conveying line (3) in a parallel mode, a boxing platform (7) is embedded between the packaging box conveying lines (100), a packaging box positioning and conveying device (6) is arranged in the side front part of the packing platform(7), and a flexible clamping apparatus (9) fixed to the front end of a mechanical arm of a robot is arranged in the side upper part of the boxing platform (7). According to the boxing machine, the integration process is simple, and accurate positioning of packaging boxes can be realized.

Owner:苏州澳昆智能机器人技术有限公司

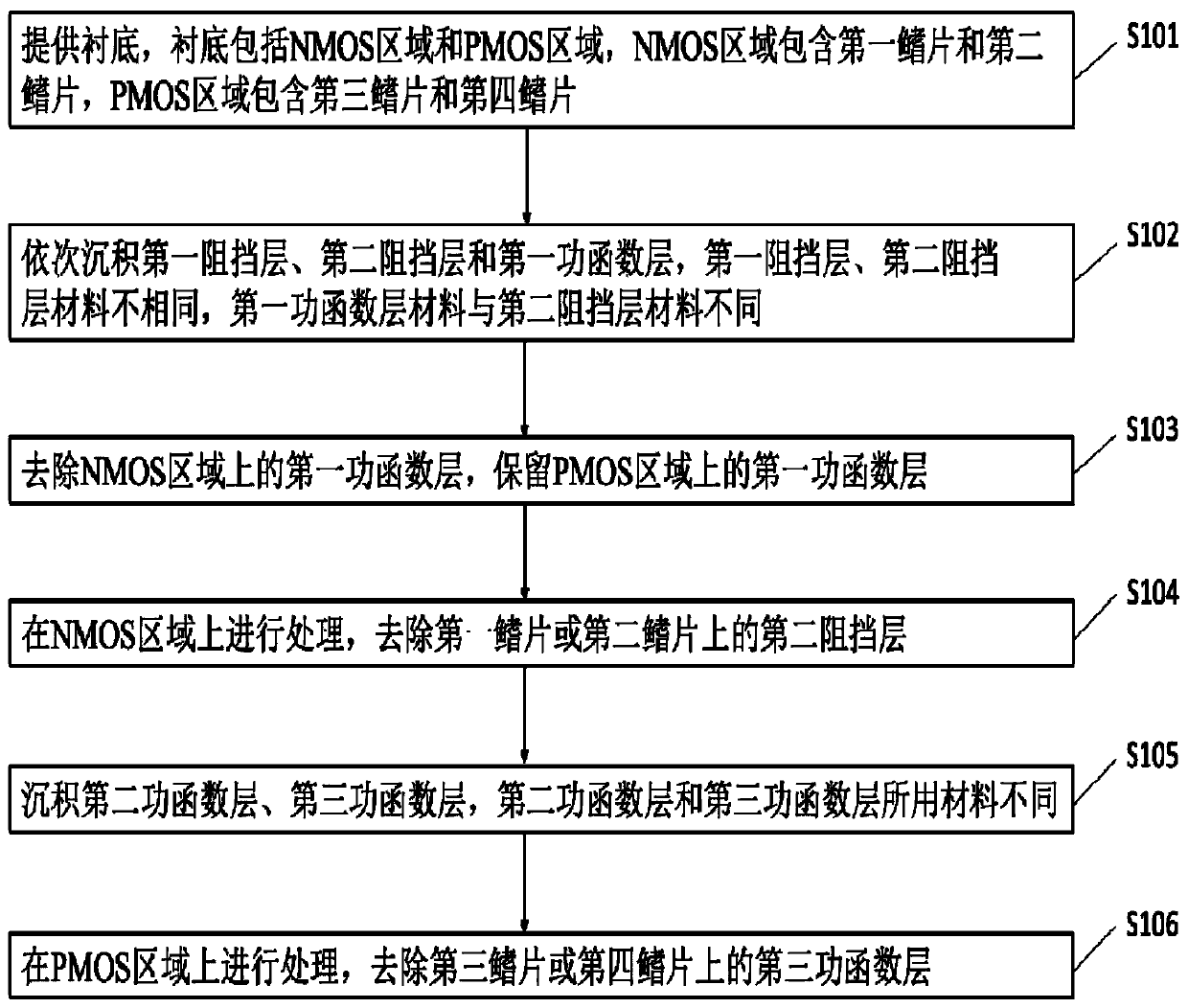

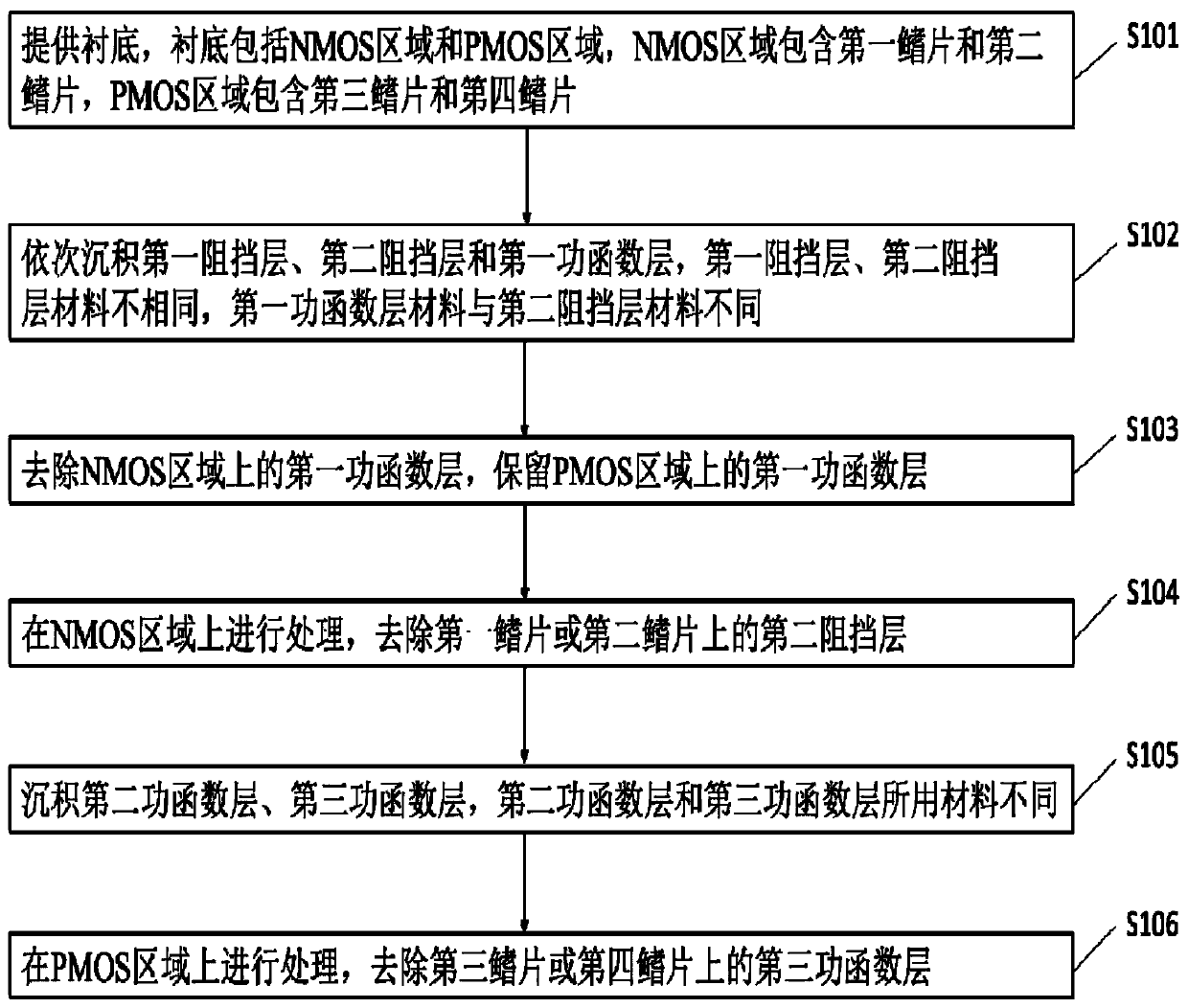

Method for adjusting threshold of high-K metal gate CMOS device and CMOS device

InactiveCN111129015AReduce process damageSimple integration processTransistorSolid-state devicesCMOSEngineering

The invention discloses a method for adjusting a threshold of a high-K metal gate CMOS device and a CMOS device, and the method comprises: providing a substrate which comprises an NMOS region and a PMOS region, wherein the NMOS region comprises a first fin and a second fin, and the PMOS region comprises a third fin and a fourth fin; sequentially depositing a first barrier layer, a second barrier layer and a first work function layer, wherein the first barrier layer and the second barrier layer are made of different materials, and the first work function layer and the second barrier layer are made of different materials; removing the first work function layer on the NMOS region; processing on the NMOS region, and removing the second barrier layer on the first fin or the second fin; depositing a second work function layer and a third work function layer, wherein the second work function layer and the third work function layer are made of different materials; and processing on the PMOS region, and removing the third work function layer on the third fin or the fourth fin.

Owner:宿州市高智信息科技有限公司

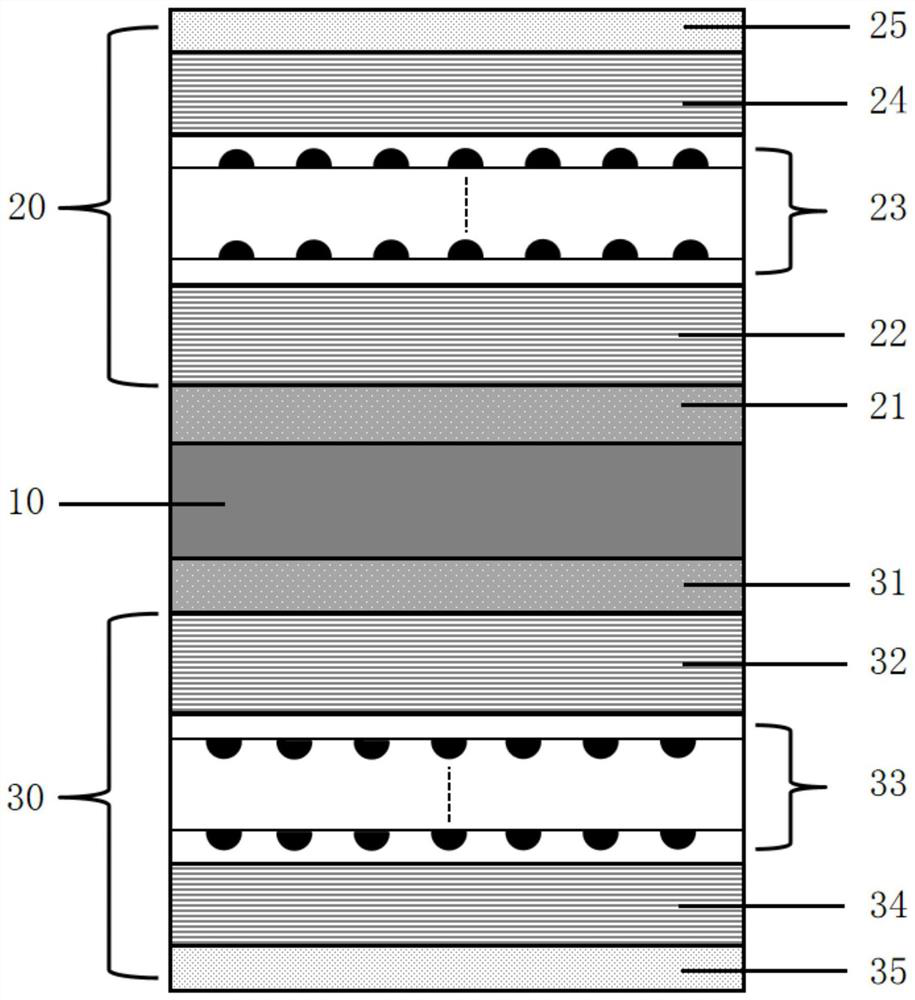

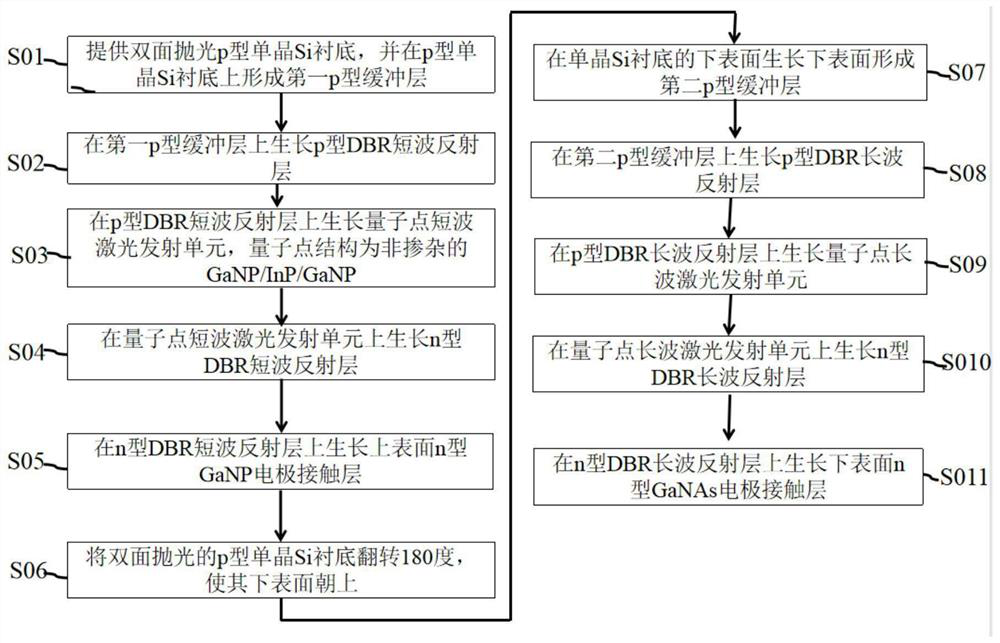

Silicon-based double-sided vertical cavity surface emitting laser and preparation method thereof

PendingCN113764969ASimple integration processReduce manufacturing costLaser detailsLaser optical resonator constructionVertical-cavity surface-emitting laserCommunications system

The invention provides a silicon-based double-sided vertical cavity surface emitting laser and a preparation method thereof. The silicon-based double-sided vertical cavity surface emitting laser comprises the following structures: a p-type monocrystalline silicon substrate subjected to double-sided polishing; a first p-type buffer layer on a surface in contact with the polished upper surface; a second p-type buffer layer on a surface in contact with the polished lower surface, wherein the material of the first p-type buffer layer is different from the material of the second p-type buffer layer; a short-wave laser emission module, wherein a quantum dot structure of the short-wave laser emission module is a non-doped GaNP / InP / GaNP; wherein the quantum dot structure of the long-wave laser emission module is non-doped GaNAs / InAs / GaNAs. According to the silicon-based double-sided vertical cavity surface emitting laser, a short wave and long wave coexisting VCSEL device can be prepared based on the monocrystalline silicon substrate, and the silicon-based double-sided vertical cavity surface emitting laser can be conveniently applied to communication systems, sensing systems, intelligent control systems and the like which are high in function integration level.

Owner:深圳市中科光芯半导体科技有限公司

Touch substrate and preparation method thereof, touch module, touch display screen and electronic equipment

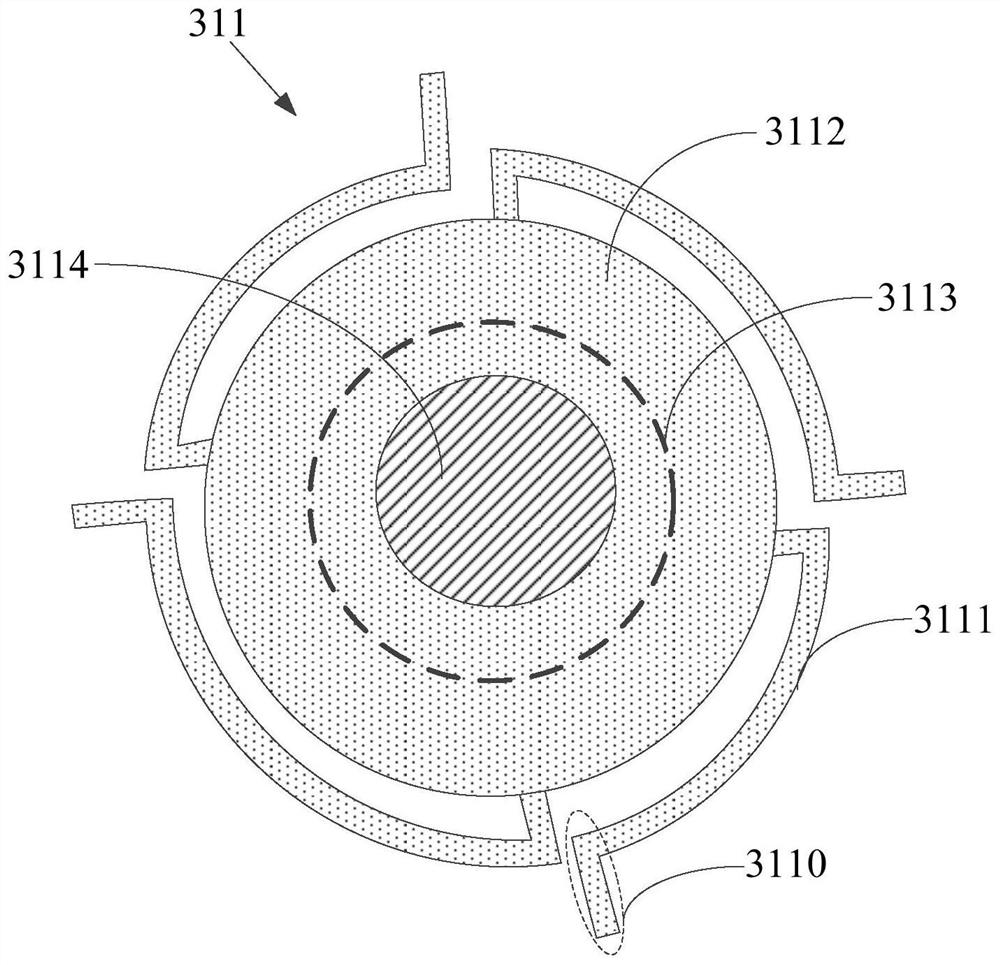

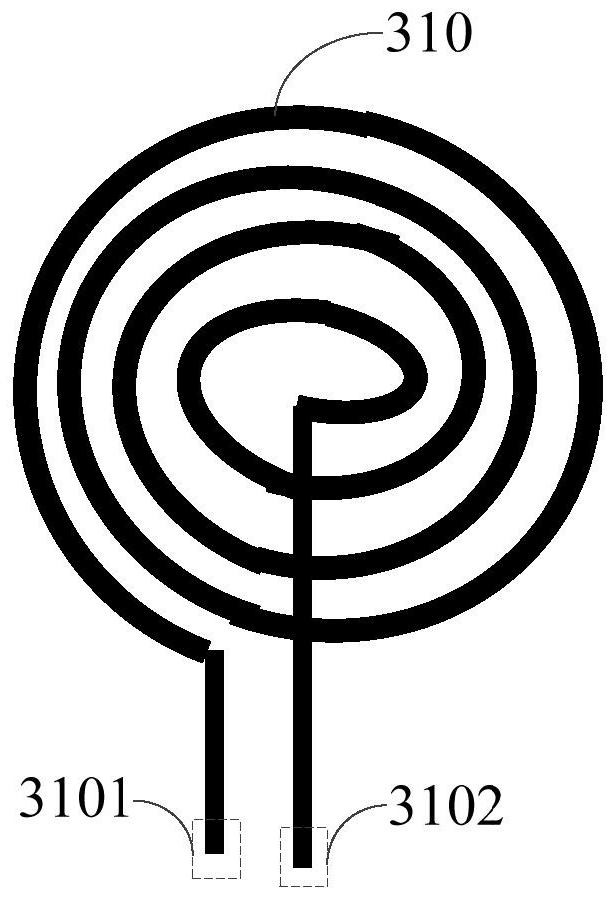

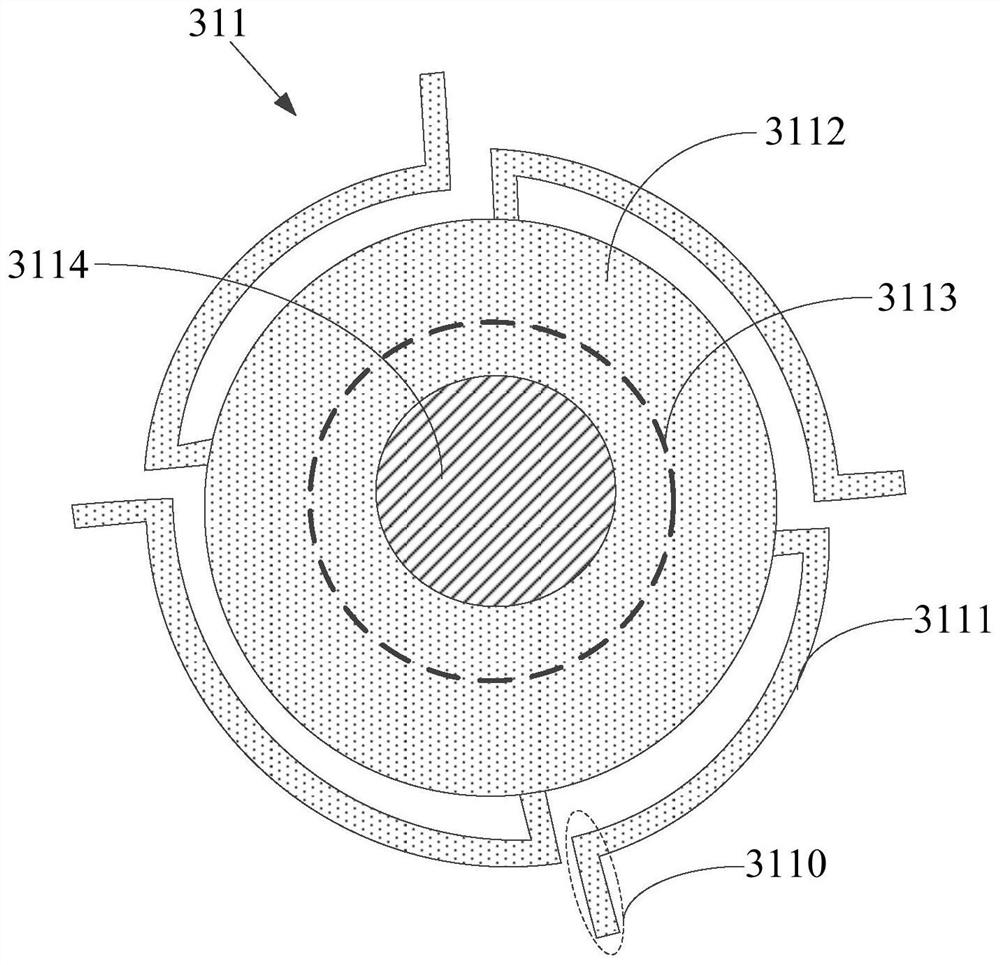

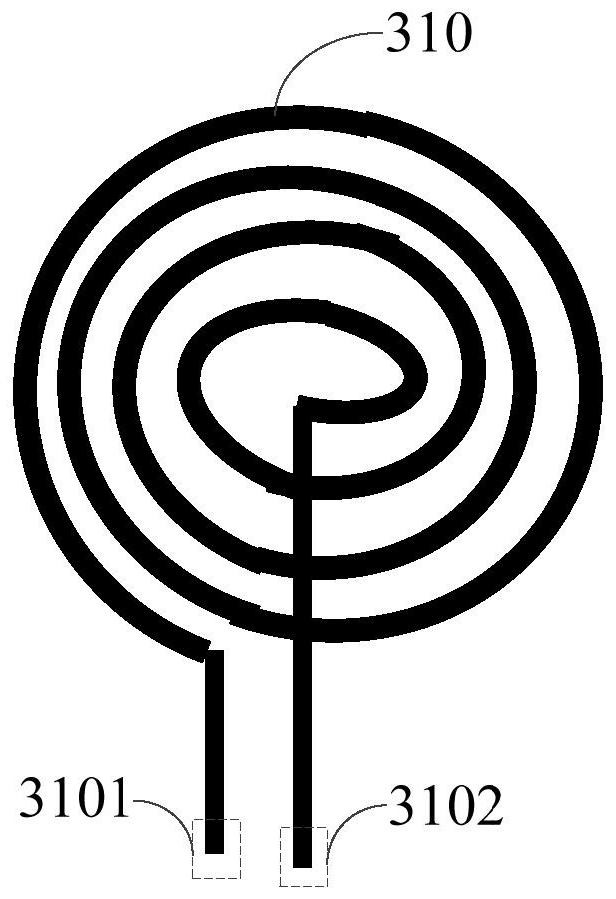

PendingCN111949155AImprove adhesionSimple integration processAntenna supports/mountingsLoop antennasPhysicsElectrical connection

The invention discloses a touch substrate, a preparation method thereof, a touch module, a touch display screen and electronic equipment. The touch substrate comprises: a substrate, wherein a first touch pattern layer and a first lead group electrically connected with the first touch pattern layer are arranged on a first surface of the substrate; and an antenna coil which is arranged on the firstsurface, wherein the antenna coil comprises a coil part and a contact part, the coil part is arranged around the first touch pattern, the contact part comprises a first contact arranged in the coil part and a second contact arranged outside the coil part, and the first contact and the second contact are used for being electrically connected to an external chip; the substrate is further provided with a first through hole penetrating through the substrate, an electric conductor is arranged in the first through hole, the end, close to the first surface, of the electric conductor is electrically connected with the first contact, and the other end of the electric conductor extends to the second surface opposite to the first surface and forms a third contact on the second surface. According to the touch substrate, the integration process of the NFC antenna is simplified, and the risk that a traditional NFC antenna is artificially damaged is eliminated.

Owner:盈天实业(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com