Touch substrate and preparation method thereof, touch module, touch display screen and electronic equipment

A touch module and substrate technology, applied in circuits, electrical components, electrical digital data processing, etc., can solve problems such as occupying battery space and NFC antenna damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

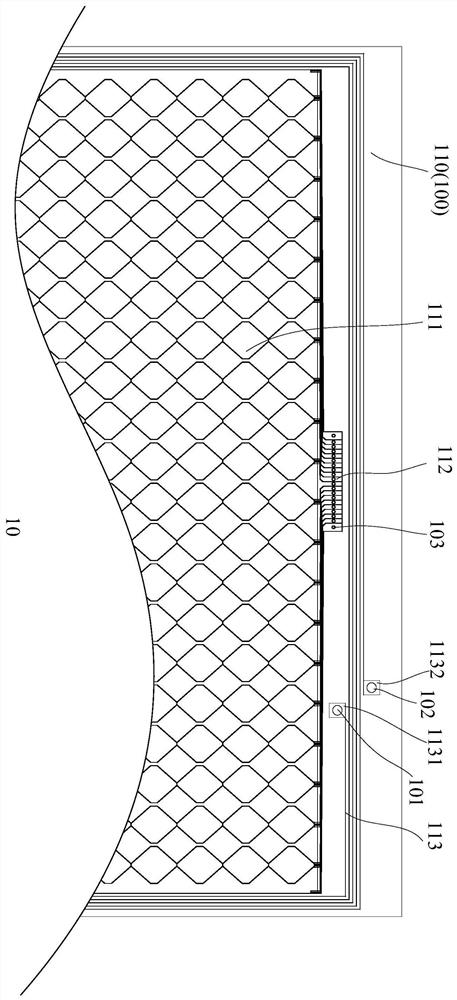

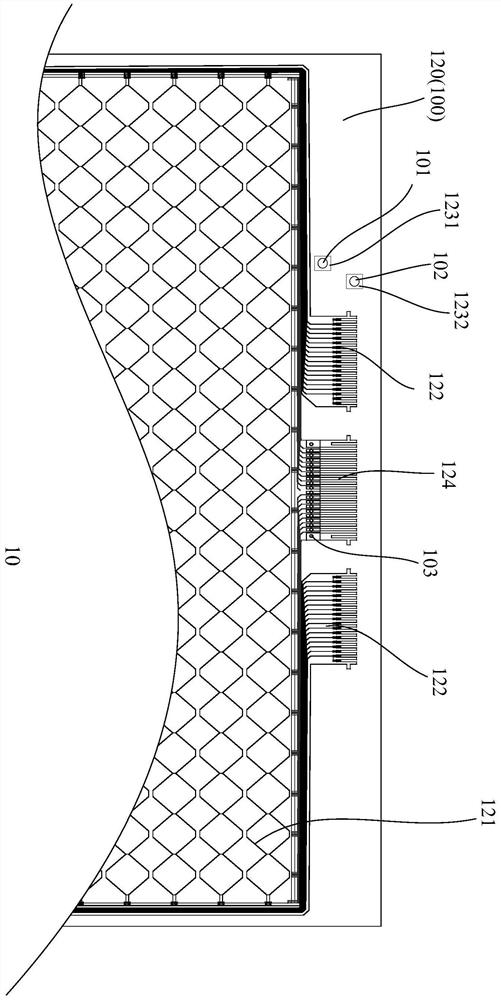

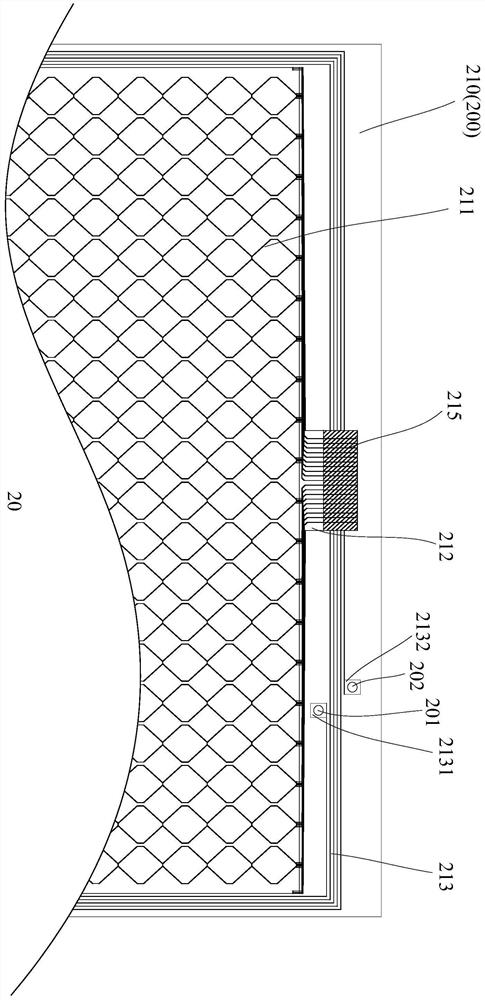

[0066] On the other hand, an embodiment also provides a method for manufacturing a touch sensor, which includes the following steps.

[0067]Coating conductive paste on the first surface of the substrate to form a first touch pattern layer, a first lead group and an antenna coil as an NFC antenna, the first lead group is electrically connected to the first touch pattern layer, and the antenna coil has a a first contact inside the coil and a second contact outside the coil;

[0068] Coating conductive paste on the second surface of the substrate to form a second touch pattern and a second lead group, the second lead group is electrically connected to the second touch pattern.

[0069] In one specific example, the preparation method further includes the following steps: forming a first insulating layer on the antenna coil, and then forming a first wire for connecting the first contact with the external chip.

[0070] In one specific example, the preparation method further inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com