Common reference electrode temperature controlled CO2-SOx integrated gas sensor and preparation method thereof

A common reference electrode, gas sensor technology, applied in the direction of material electrochemical variables, etc., can solve the problems of slow response and high power consumption of gas sensors, and achieve the effects of fast response speed, reduced volume, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

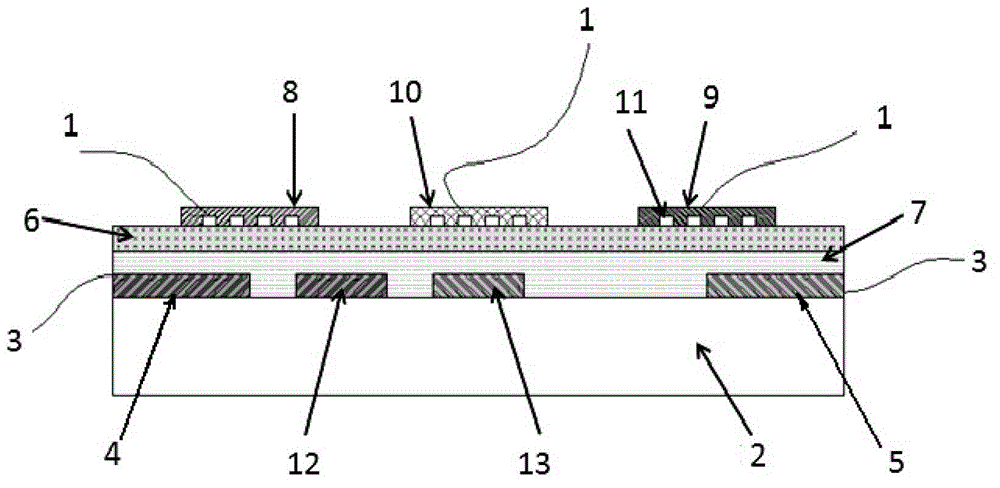

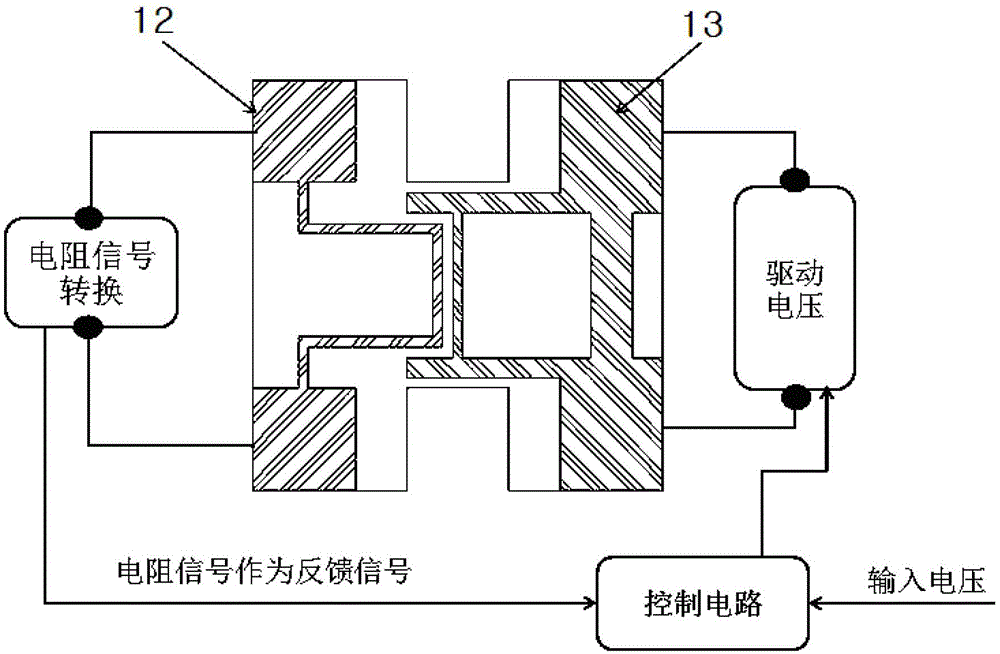

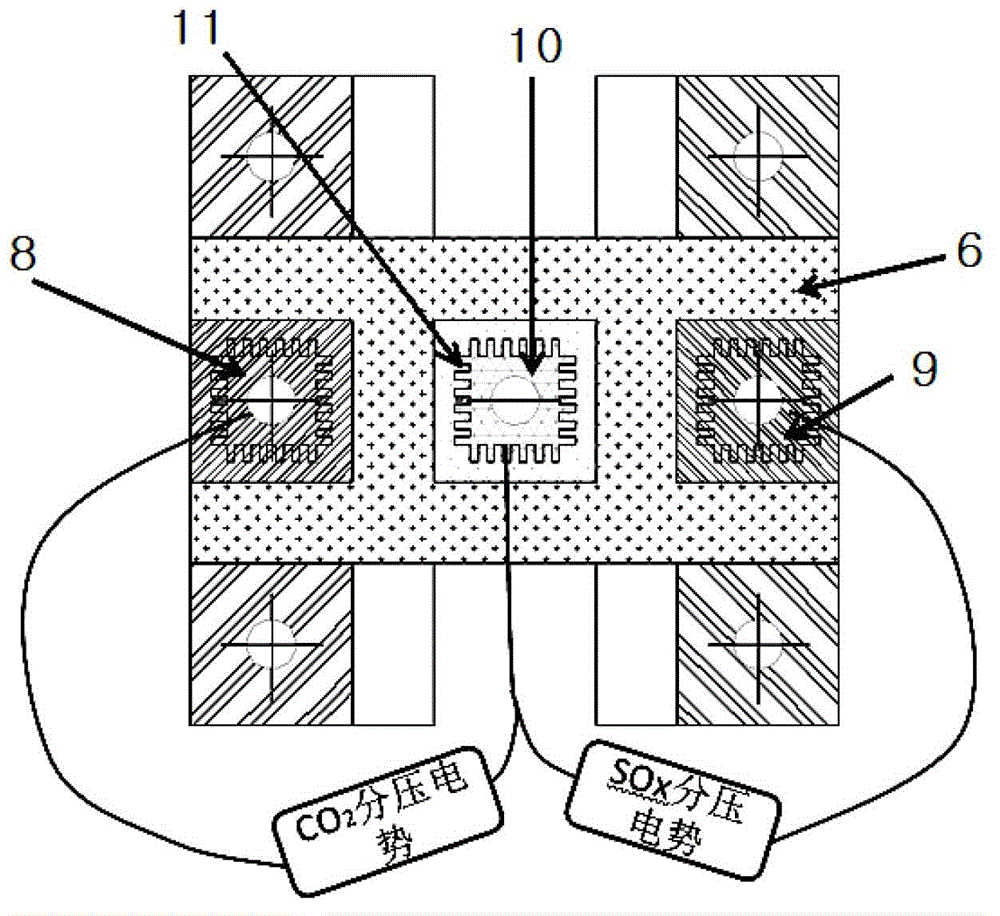

[0027] Such as figure 1 , image 3 As shown, a common reference electrode temperature-controlled CO 2 -SOx integrated gas sensor, from bottom to top in the figure are alumina substrate 2, heating element 13 and temperature measuring element 12, insulating layer 7, Li 3 PO 4 Solid electrolyte film 6, Au toothed film electrode 11, CO 2 Reaction electrode 8 (Li 2 CO 3 ), SOx reaction electrode 9 (Li 2 SO 4 -CaSO 4 ) and common reference electrode 10 (Li 2 TiO 3 -TiO 2 ), 1 and 3 are Pt leads; 4 and 5 are lead plates.

[0028] Above CO 2 -In the structure of the SOx integrated gas sensor, the heating element 13 and the temperature measuring element 12 are about 15 microns of Pt (or RuO 2 ) thick film, which is printed on the alumina substrate by screen printing and sintered to form the final heating and temperature measuring element, Pt (or RuO 2 ) thick film is two independent structures, and each thick film structure has two independent lead pads 4, 5 at both ends ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com