A method for forming an air gap

An air-gap and sheet-like technology, applied in the field of air-gap, can solve the problems of increased effective dielectric constant, complicated process, and narrowed grooves, and achieve the effects of improving product performance, simplifying the integration process, and increasing the forming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

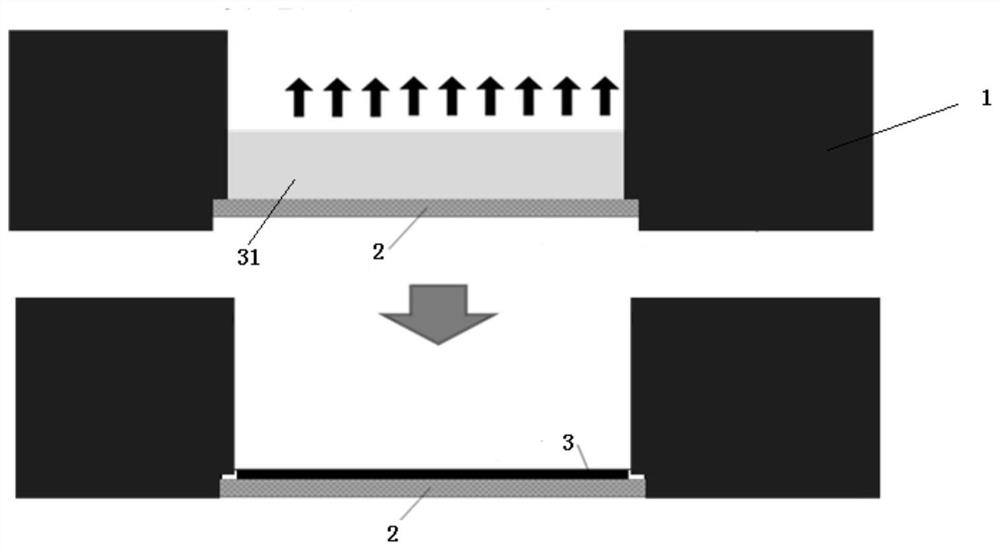

[0047] The process of sealing the air gap to be sealed by the insulating sheet-shaped two-dimensional material solution can be carried out in the following two ways:

[0048] The first way is to use the method of multiple spin coating, that is, the graphene oxide solution is spin coated on the solid medium on both sides of the groove for many times, and after each spin coating, it will be dried quickly with a hot plate, and through multiple spin coating Form a film composed of graphene oxide above the groove, and remove the solvent in the film with a long-time (for example 30min) heat treatment after multiple spin coatings, so that the film composed of graphene oxide becomes more stable; thus Seal the groove to create an air gap.

[0049] The second method adopts the immersion film forming method, that is, the solid medium containing the above-mentioned grooves is immersed in the graphene oxide solution, and the solvent is evaporated by slow heating, thereby forming graphite o...

Embodiment 2

[0054] Please refer to the attached Figure 3-6 , the concrete method of forming the air gap between metals comprises the following steps:

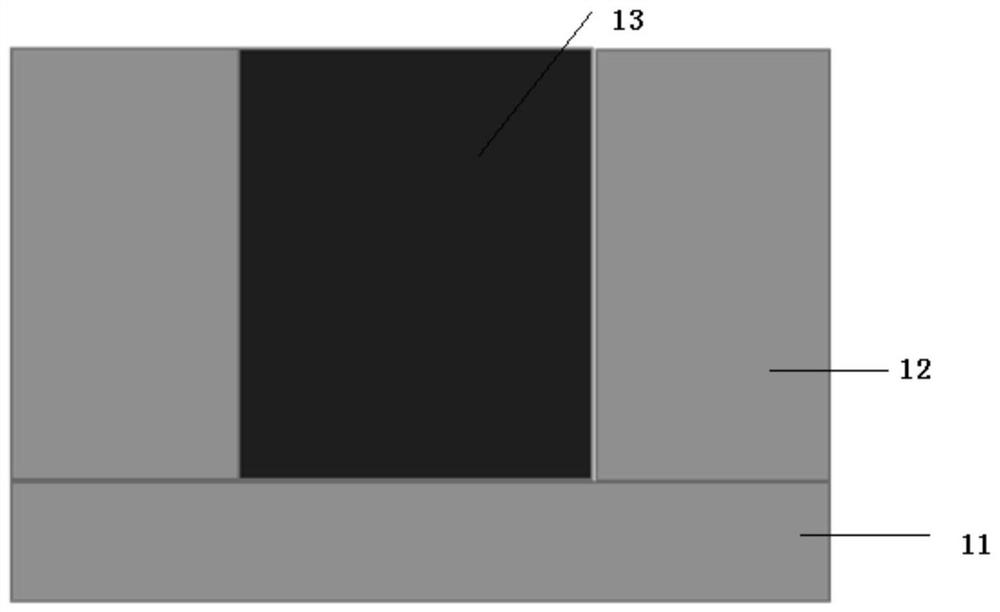

[0055] S01: Please refer to the attached image 3 The metal layer 12 and the isolation dielectric layer 13 are deposited on the silicon wafer 11 at the same time, and the isolation dielectric layer 13 and the metal layer 12 have a high selectivity etching coefficient.

[0056] S02: Please refer to the attached Figure 4 , using a dielectric etching process to remove the isolation dielectric layer 13, because the metal layer 12 and the isolation dielectric layer 13 have a high selectivity ratio, the metal layer 12 remains basically unchanged, thereby forming grooves between the metal layers.

[0057] S03: Please refer to the attached Figure 5 A layer of dielectric protection layer 14 is deposited on the upper surface and side walls of the metal layer 12; the function of the dielectric protection layer is to protect the metal layer from...

Embodiment 3

[0062] Please refer to the attached Figure 8, the specific method of forming the air gap between insulating dielectric layers is as follows: after forming the intermetallic air gap 17 in embodiment 2, deposit an insulating dielectric layer 16 on the thin film composed of insulating sheet-like two-dimensional material, so that the intermetallic air gap 17 is staggered The insulating medium layer is etched at the position, and stops on the thin film composed of insulating sheet-like two-dimensional material to form a groove between the insulating medium layers, and the insulating sheet-like two-dimensional material solution is coated on the insulating medium layer to form a A thin film composed of insulating sheet-like two-dimensional material on the groove forms an air gap 18 between insulating dielectric layers sealed with insulating sheet-like two-dimensional material. The specific method of coating the insulating sheet-like two-dimensional material is as described in Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com