Rotor punching sheet for outer rotor motor of household electric appliance fan

A technology for household appliances and rotor punching, which is applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc. It can solve the problems of small motor starting torque, small size of the bottom of the rotor slot, affecting motor efficiency and electromagnetic noise, etc. Achieve the effect of reducing the loss of copper or aluminum, reducing the amount of raw materials, and improving the efficiency of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

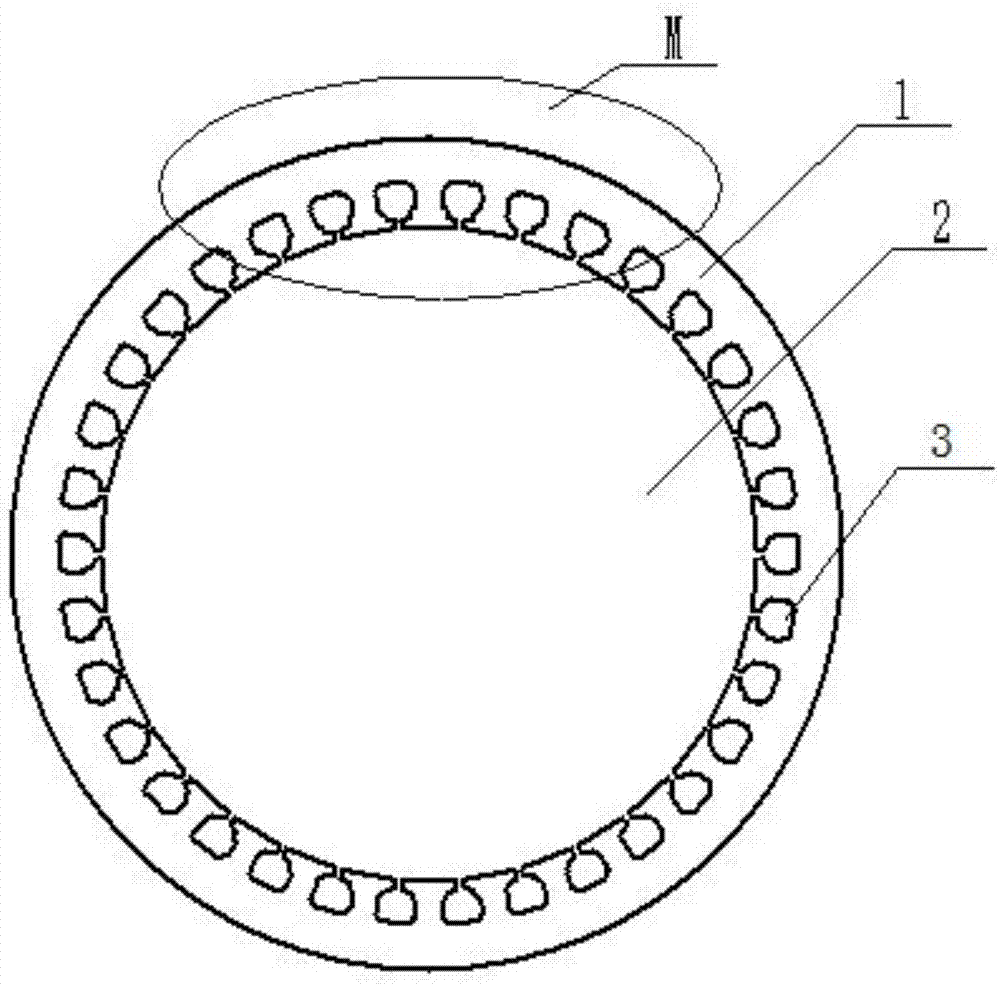

[0019] A rotor punching based on the outer rotor motor of a fan of a household appliance, comprising a punching body 1, the punching body 1 is disc-shaped, and an inner circular hole 2 and a punching groove 3 are opened on the surface of the punching body 1. The center of the inner hole 2 coincides with the center of the punch body 1, such as figure 1 shown;

[0020] Preferably, the diameter of the punch body 1 is 90-98mm, and the diameter of the inner hole 2 is 72-80mm;

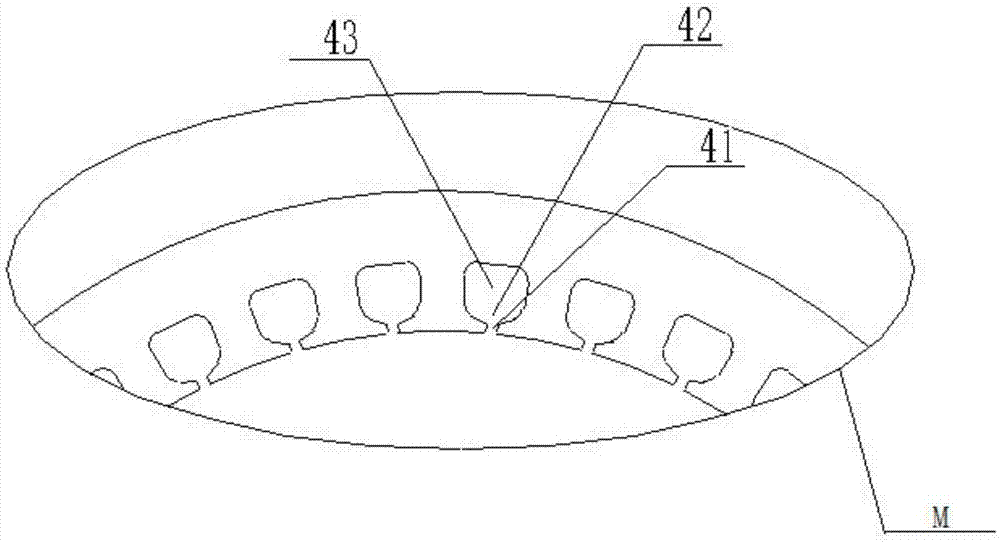

[0021] like figure 2 As shown, there are punching slots 3 evenly distributed around the inner hole 2, and the punching slots 3 include a notch 41, a groove shoulder 42, and a slot body 43. Preferably, there are 34 evenly distributed around the inner hole 2. a punching slot 3;

[0022] The notch 41 is a rectangular hole, the width of the notch 41 is 0.6-1.2mm, and the height is 0.4-1.0mm;

[0023] The groove shoulder 42 is a trapezoidal hole, the groove shoulder 42 is connected with the notch 41, the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com