Leek harvester

A technology for harvesting machines and leeks, applied in harvesting machines, agricultural machinery and tools, agriculture, etc., can solve the problems that restrict the development of leek planting industry, high temperature and humidity, and low harvesting efficiency, so as to improve harvesting efficiency and achieve good cutting quality , the effect of reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

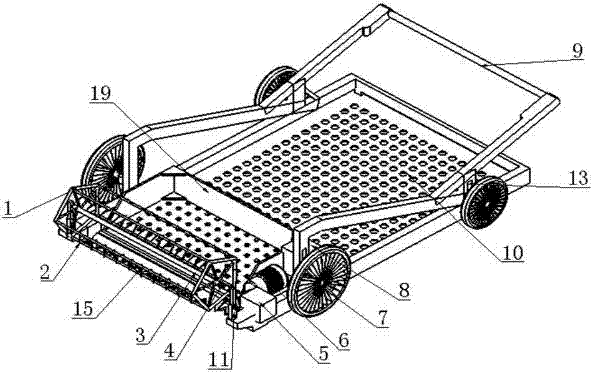

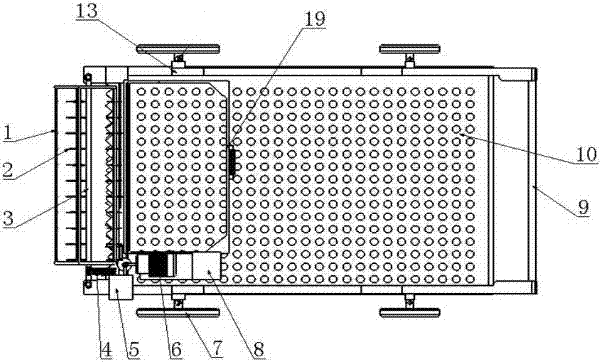

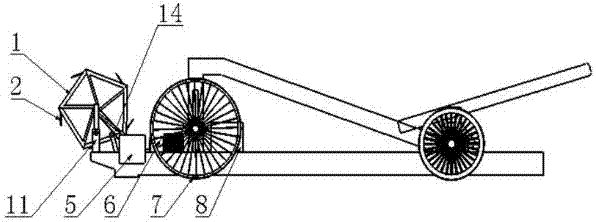

[0030] Such as figure 1 A kind of leek harvester shown, comprises frame and four traveling wheels 7 that are installed on the frame, the frame rear end is provided with handrail 9 that is easy to push, and the frame front end is equipped with the reel driven by motor 6 rotation 1. The reel 1 includes a wheel shaft 3 fixedly connected to the motor output shaft 18 of the motor 6, and a wheel body fixedly connected to the wheel shaft 3. The side of the wheel body is a pentagonal structure, and the surface of the wheel body is fixed with an edge Shift forks 2 arranged at intervals in the length direction.

[0031] In order to reduce the weight, the two sides of the wheel body are short rods that are connected head to tail in turn. The short rods on both sides are connected as a whole through long rods. The wheel axle is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com