Straw recovering, smashing and cutting machine

A technology for cutting machinery and straw, which is applied in the field of straw recycling, crushing and cutting machinery, which can solve the problems of imperfect cutting, inability to cut and crush, and insufficient functions, and achieve the effects of good product quality, convenient use, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

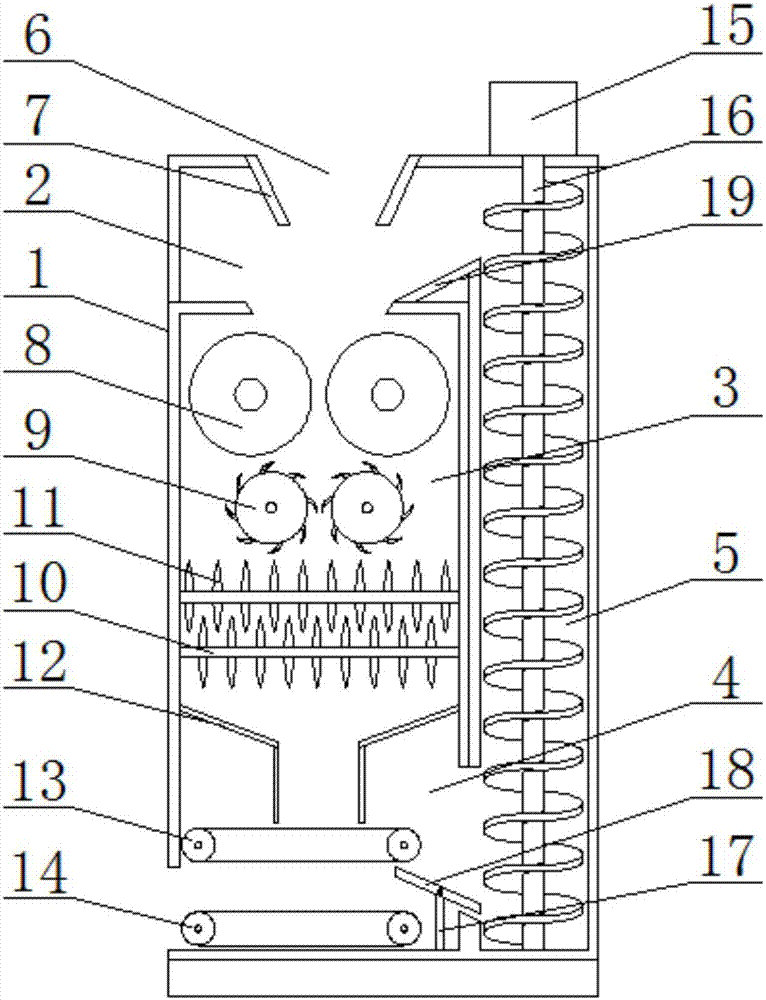

[0018] Example: such as figure 1 As shown, a straw recycling crushing and cutting machine of the present invention includes a casing 1, and the casing 1 includes a feeding chamber 2, a crushing chamber 3, a discharging chamber 4 and a lifting chamber 5, the feeding chamber 2, and the discharging chamber 4 They are respectively located at the upper end and lower end of the crushing chamber 3. The lifting chamber 5 is located on the right side of the feeding chamber 2, crushing chamber 3 and discharge chamber 4. The upper end of the feeding chamber 2 is provided with a feeding port 6. The upper end of the crushing chamber There are two rolling rollers 8, the rotating shaft of the rolling rollers 8 is rotatably connected with the inner wall of the casing 1, and a saw blade 9 is located below the rolling rollers 8 in the crushing chamber 3, and the saw blades 9 are fixed on the rotating shafts , and the rotating shaft on the saw blade 9 is rotationally connected with the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com