Horizontal type foaming production line for water tank of solar water heater

A solar water tank and production line technology, applied in the field of solar water tank foaming, can solve the problems of complex structure, low degree of automation, and low production efficiency of the foaming production line, and achieve the goals of facilitating large-scale automatic production, high automation level, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

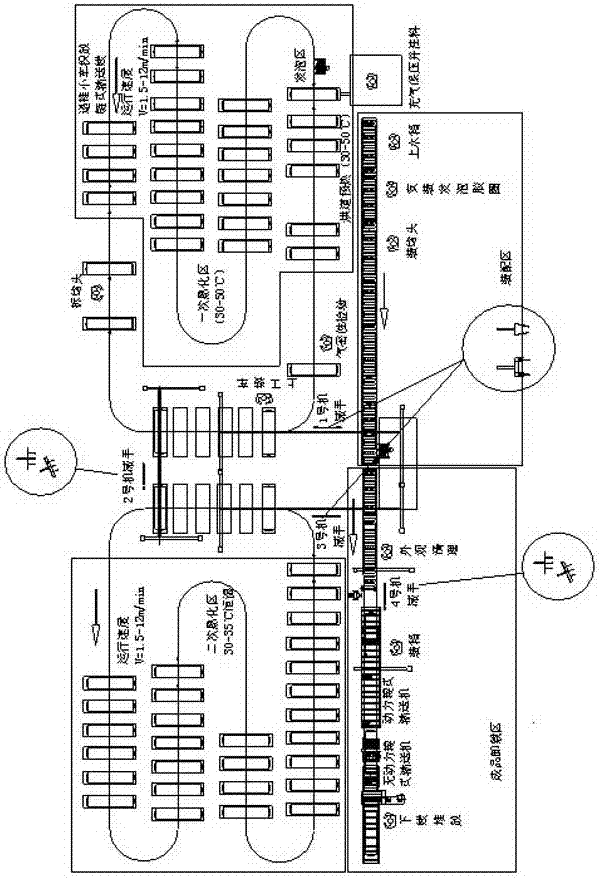

[0035] Such as figure 1 , 4 As shown, the solar water tank horizontal foaming production line includes the water tank assembly area, foaming area, aging area and finished product unloading area. The foaming area and the aging area are located on the circular track, and there is a No. No. 3 manipulator is set between the ripening area and the finished product unloading area. The aging area is divided into a primary aging area and a secondary aging area, wherein the primary aging area and the foaming area are located on the No. 1 circular track, and the secondary aging area is located on the No. 2 circular track. There is a No. 2 manipulator between the two circular tracks. The primary curing area and the secondary curing area are distributed on two circular tracks, which can improve the utilization rate of the tooling vehicles in the foaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com