Method for treating radioactive wastewater by utilizing microwave-Fenton method

A radioactive wastewater and microwave treatment technology, which is applied in the direction of radioactive pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow degradation speed, insufficient degradation of organic matter, and insufficient reaction efficiency, so as to improve degradation efficiency, The effect of improving the degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

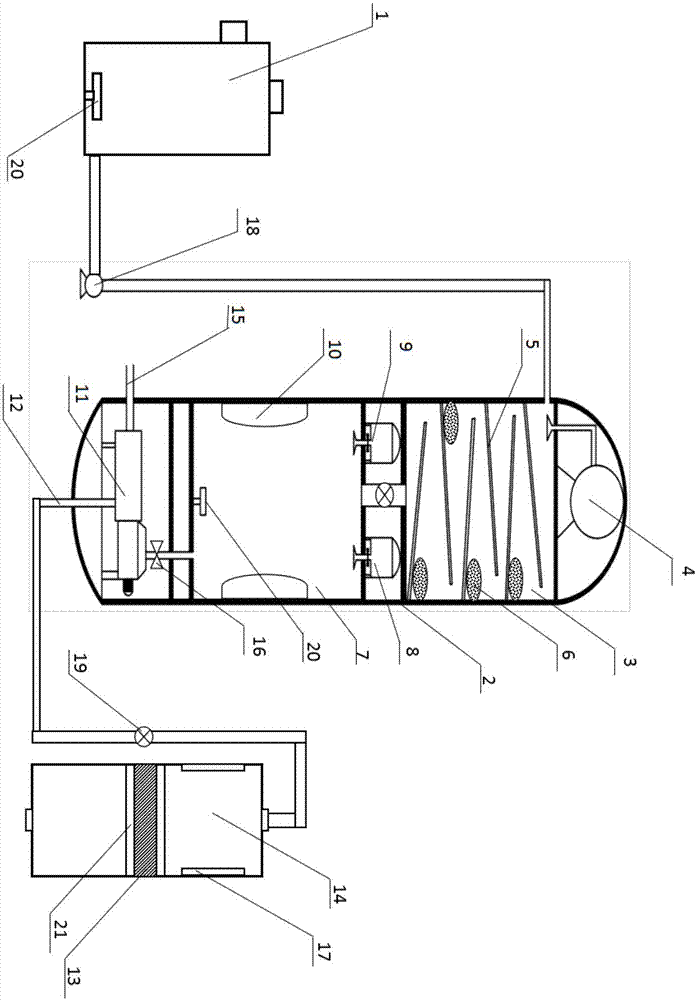

[0025] figure 1 Show the microwave-Fenton method of the present invention to process the device of radioactive waste water; A kind of microwave-Fenton method process the method for radioactive waste water, comprise the following steps:

[0026] Step 1. Input the radioactive waste water into the pH adjustment tank 1, adjust the pH of the radioactive waste water to 2-3, pass the adjusted radioactive waste water through the feed liquid pump 18 at a rate of 1m 3 The speed input of / h is positioned at the Fenton oxidation chamber 3 of treatment device 2 tops; Open the Fenton reagent spraying device 4 of Fenton oxidation chamber 3 tops, spray Fenton reagent to radioactive waste water with the speed of 100mL / min; Said Fenton oxidation reaction chamber 3 A plurality of inclined overflow deflectors 5 are arranged at intervals on both sides of the interior; radioactive waste water flows downward along the plurality of inclined overflow deflectors 5 to achieve degradation treatment; the ov...

Embodiment 2

[0032] A method for treating radioactive waste water by microwave-Fenton method, comprising the following steps:

[0033] Step 1: Input the radioactive waste water into the pH adjustment tank 1, adjust the pH of the radioactive waste water to 2-3, pass the adjusted radioactive waste water through the feed liquid pump 18 at a rate of 2m 3 The speed input of / h is positioned at the Fenton oxidation chamber 3 of treatment device 2 tops; Open the Fenton reagent spraying device 4 of Fenton oxidation chamber 3 tops, spray Fenton reagent to radioactive waste water with the speed of 250mL / min; Said Fenton oxidation reaction chamber 3 A plurality of inclined overflow deflectors 5 are arranged at intervals on both sides of the interior; radioactive waste water flows downward along the plurality of inclined overflow deflectors 5 to achieve degradation treatment; the overflow deflectors 5 are fixedly arranged with Accommodating a screen bag 6 of a solid-phase catalytic promoter; a solid-p...

Embodiment 3

[0039] A method for treating radioactive waste water by microwave-Fenton method, comprising the following steps:

[0040] Step 1: Input the radioactive waste water into the pH adjustment tank 1, adjust the pH of the radioactive waste water to 2-3, pass the adjusted radioactive waste water through the feed liquid pump 18 at a rate of 1.5m 3 The speed input of / h is positioned at the Fenton oxidation chamber 3 of treatment device 2 tops; Open the Fenton reagent spraying device 4 of Fenton oxidation chamber 3 tops, spray Fenton reagent to radioactive waste water with the speed of 250mL / min; Said Fenton oxidation reaction chamber 3 A plurality of inclined overflow deflectors 5 are arranged at intervals on both sides of the interior; radioactive waste water flows downward along the plurality of inclined overflow deflectors 5 to achieve degradation treatment; the overflow deflectors 5 are fixedly arranged with Accommodating a screen bag 6 of a solid-phase catalytic promoter; a solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com