Steel-wood combined template system for water concrete arc-branch-shaped beam-column joint and construction method of template system

A technology of fair-faced concrete and formwork system, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., and can solve the problems of difficult control of finished product effect, difficult operation of workers, and grout leakage in joints. It achieves the effects of convenient adjustment, reduced operation difficulty and safety risks, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment discloses a steel-wood combined formwork system for fair-faced concrete arc-shaped branch-shaped beam-column joints, including a combined steel formwork 1 for the arc section at the top of the column that is fixedly connected to the base 5, and four arc steel forms 2 And 4 pieces of angle steel mold Ⅲ3.

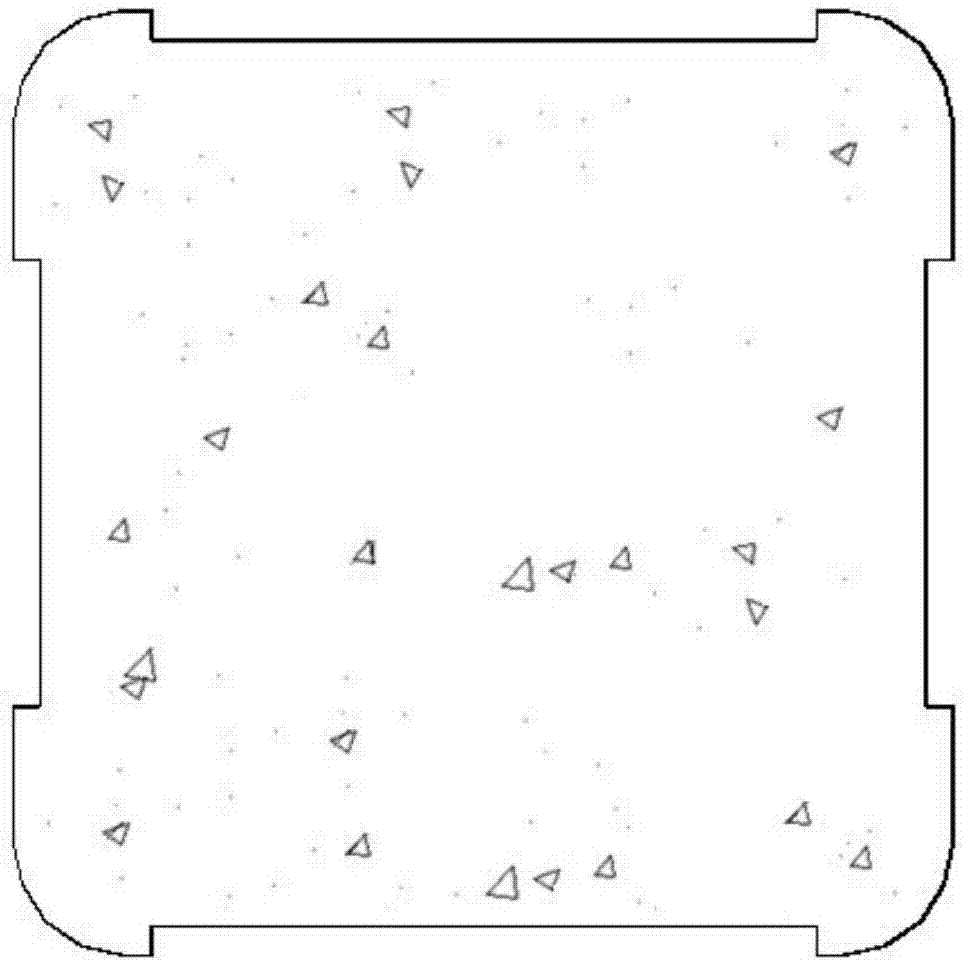

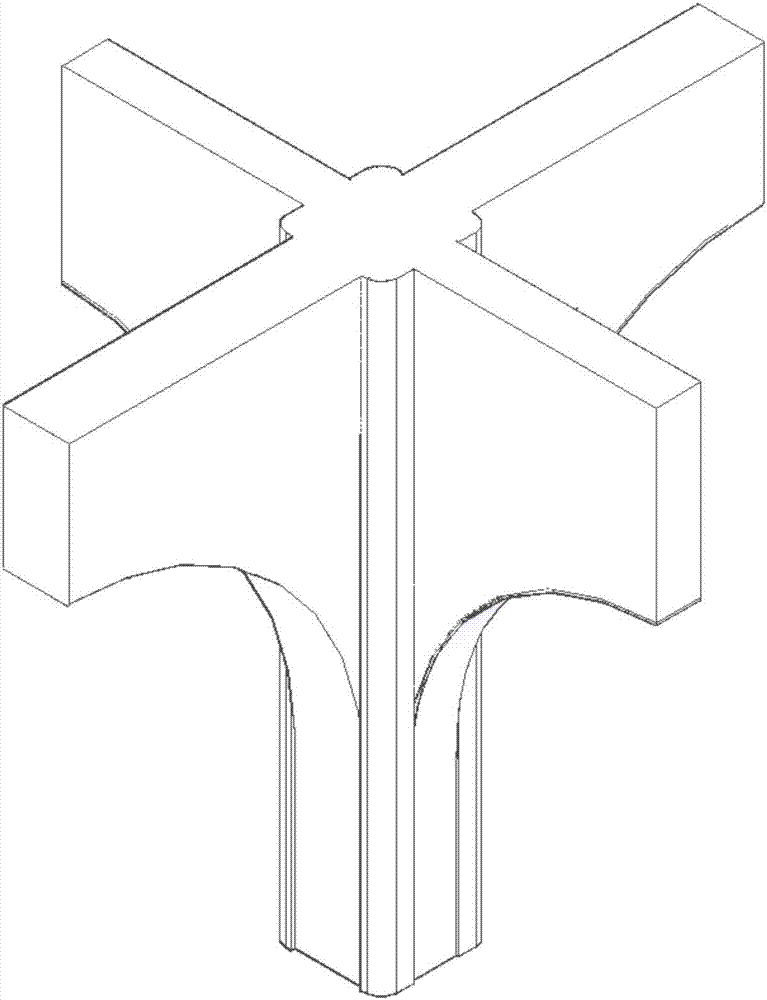

[0045] see figure 1 , the cross-section of the column body is rounded rectangle as a whole (that is, the four corners of the rectangle are replaced by 1 / 4 arcs). Grooves are provided on the four sides of the rounded rectangle. see figure 2 , The junction between the top of the canopy column and the beam adopts an arc connection form, and the four grooves on the top of the column are connected to the beam in an arc. The widths of the four groove surfaces of the column are respectively equal to the widths of the corresponding beams.

[0046] After the pouring of the column body is completed and before the construction of the upper structure, a steel ...

Embodiment 2

[0053] This embodiment discloses a steel-wood combined formwork system for fair-faced concrete arc-shaped branch-shaped beam-column joints, including a combined steel formwork 1 for the arc section at the top of the column that is fixedly connected to the base 5, and four arc steel forms 2 And 4 pieces of angle steel mold Ⅲ3.

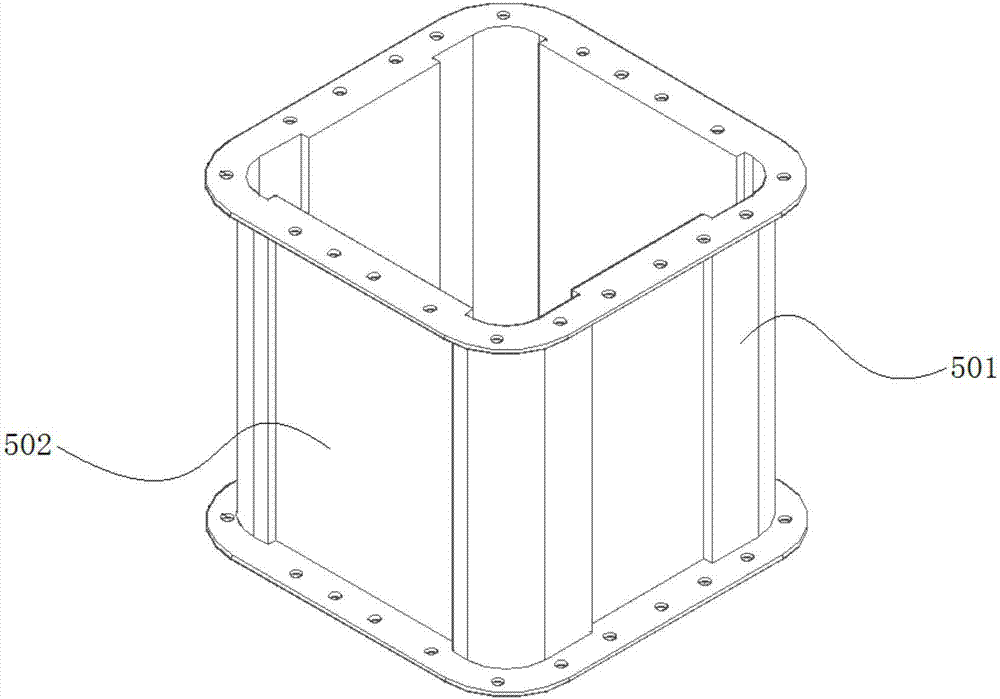

[0054] The base 5 is a column body steel formwork that is closed and connected to the column. The base 5 is a sash formwork closed all around. The base 5 as a whole is a rectangular frame with rounded corners. There are long grooves on the four sides of the frame. The base 5 includes 4 angle steel molds I 501 and 4 grooved panels 502 . The angle steel mold I501 includes a curved panel I5011. The two sides of the curved panel I5011 are connected with end plates I5012. The end plate I5012 is located on the concave side of the curved panel I5011. The grooved panel 502 is a straight steel plate. The four angle steel molds I501 correspond to the four ...

Embodiment 3

[0061] This embodiment discloses a construction method related to the above-mentioned formwork system, including the following steps:

[0062] 1) Construction preparation, template pre-assembly, to avoid rework.

[0063] 2) Carry out anti-corrosion treatment on the base 5, combined steel mold 1, arc steel mold 2 and angle steel mold III3.

[0064] 3) After the pouring of the lower column is completed and before the construction of the upper structure, the base 5 is installed on the top of the column, and double-sided adhesive tape is pasted on the joint between the base and the concrete to ensure that the upper structure does not leak when the concrete is poured.

[0065] 4) Install the combined steel mold 1 on the base 5, and paste double-sided adhesive tape on the junction of the templates.

[0066] 5) Install the arc steel mold 2 on the upper end of the grooved panel 102 of the combined steel mold 1, and paste double-sided adhesive tape on the junction of the templates. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com