Oxygen controlling system of metallurgical industry

A control system, metallurgical industry technology, applied in pipeline systems, manufacturing converters, gas treatment applications, etc., can solve the problems of wasting oxygen supply, adjusting the start and stop of air separation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

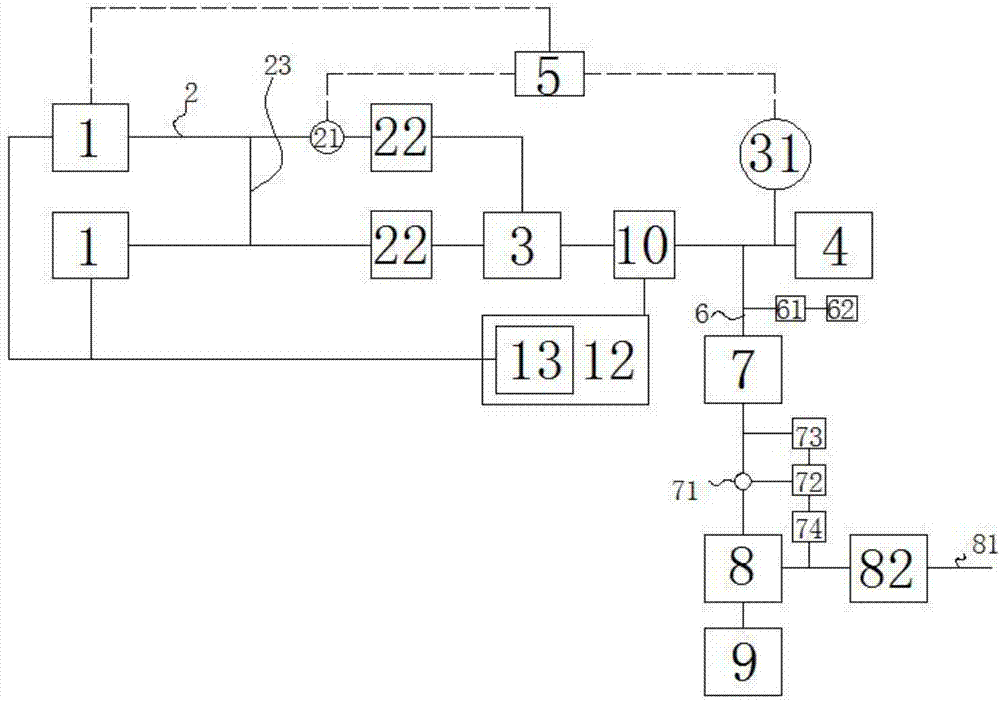

[0019] Such as figure 1 As shown, a metallurgical industry oxygen control system includes an air compressor 1, the air compressor 1 is several air compression equipment with the same or different power, the air compressor 1 is used to separate the air from oxygen, and Oxygen is liquefied by the liquefier 22 through the oxygen pipeline 2 and sent to the liquid oxygen storage tank 3 , and each air compressor 1 is connected in parallel to the liquid oxygen storage tank 3 .

[0020] The output end of the liquid oxygen storage tank 3 is connected to the steelmaking equipment 4, and the pipeline at the output end of the liquid oxygen storage tank 3 is located near the steelmaking equipment 4 to be provided with an oxygen pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com