Combined microwave sensor and dielectric constant measurement method for measured object

A technology for microwave sensors and objects to be measured, applied in measurement devices, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve the problems affecting the accuracy of measurement, increase the cost and difficulty of processing, etc. Wide availability, accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with specific embodiments in conjunction with the accompanying drawings.

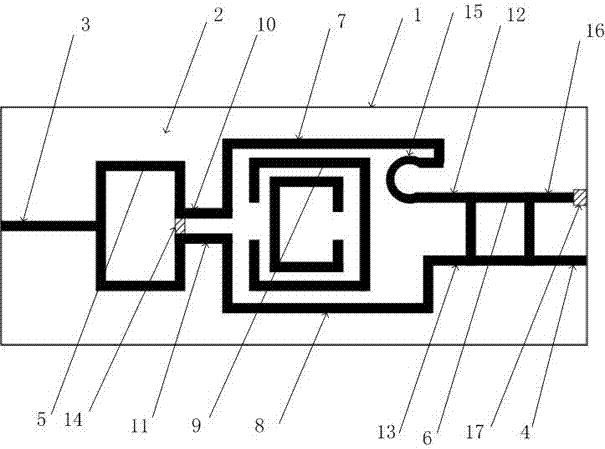

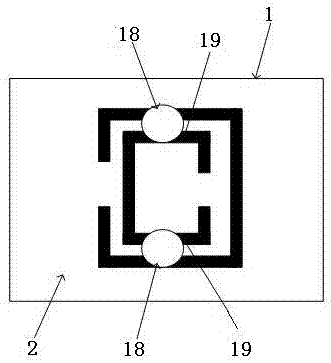

[0027] like figure 1 As shown, a composite microwave sensor is a two-port device, which consists of a metal ground 1 on the bottom layer, a medium 2 on the middle layer, and a measuring device on the top layer; the measuring device includes input port 3, output port I4, branch line coupling Device 6, power splitter 5, split resonant ring 9, 50-ohm microstrip line I7 and 50-ohm microstrip line II8.

[0028] The input port 3 and the output port I4 are connected with the vector network analyzer; the output side of the branch line coupler 6 is provided with an isolation port 16 and the output port I4; the input end of the power splitter 5 is connected with the input port 3, and the power splitter The output port II10 of 5 communicates with the port I12 of the branch line coupler 6 through the microstrip line I7; the output port III11 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com