A method of optimizing blanking process parameters

A technology of process parameters and punching, which is applied in the field of optimizing punching process parameters, and can solve problems such as restricting punching production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for optimizing blanking process parameters.

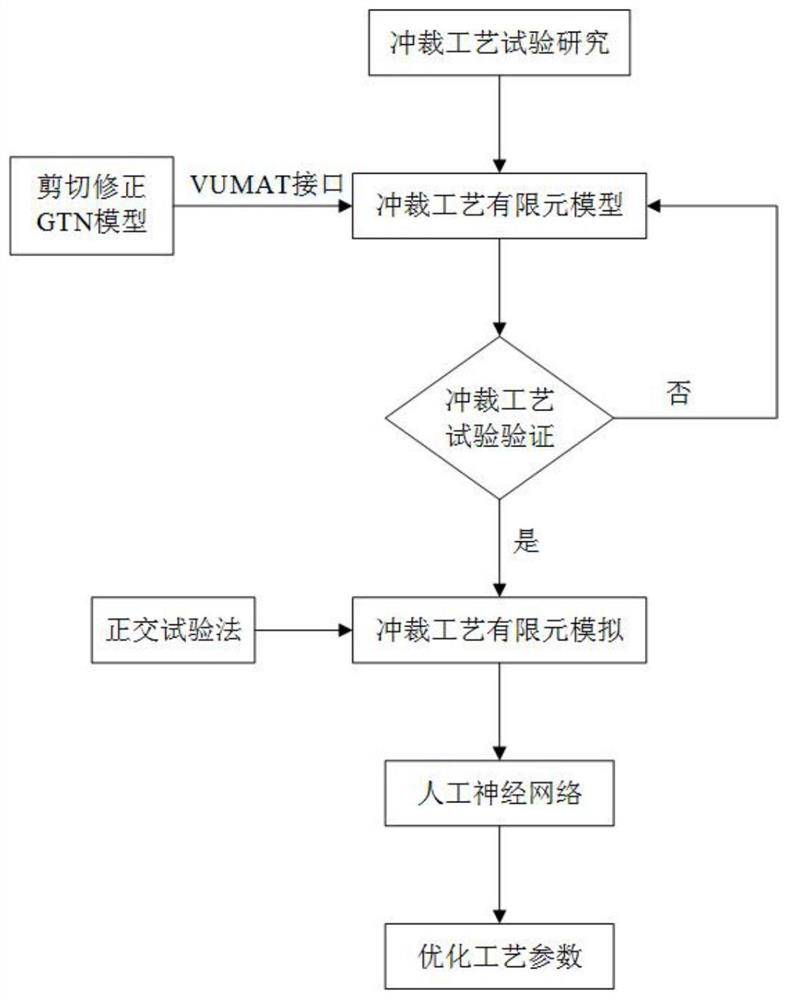

[0051] The method includes the following steps:

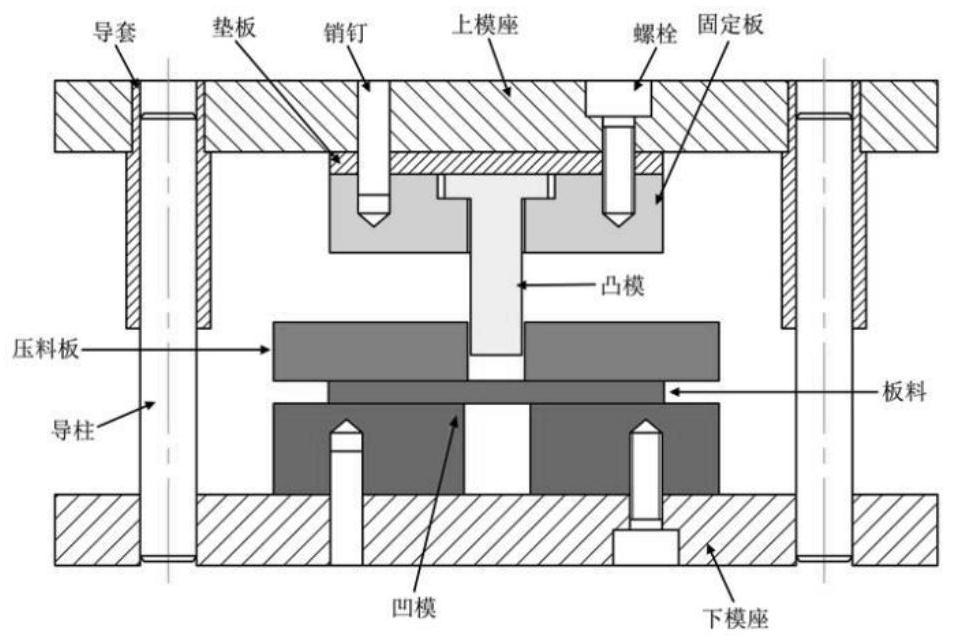

[0052] 1) Carry out punching process test: This step can be carried out on a special press or a self-designed punching device on a tensile testing machine, and simultaneously record the punching force-stroke curve. After punching, the measurement includes collapse angle, brightness The size of the characteristic area of each punching section including the band, fracture zone and burr; this embodiment uses a self-designed punching test device, such as figure 2 As shown, it was installed on the tensile testing machine for punching test. Among them, the diameters of the punch and die are 5.00mm and 5.15mm, the fillet radius is 0.05mm, the punching speed is 20mm / s, the sheet material used is 1.0mm thick non-oriented silicon steel, and the constitutive relation is where the reference strain rate

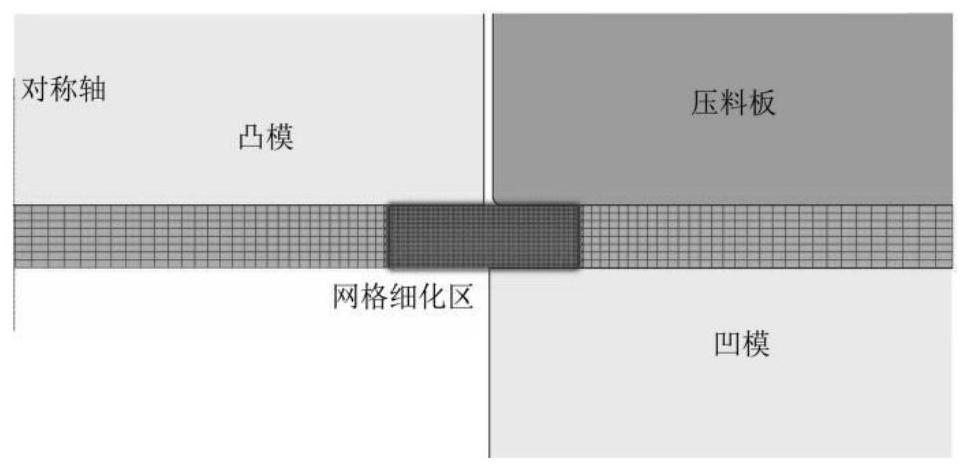

[0053] 2) Establish a blanking finite ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com