A Parametric Design Method of Lobe Mixer

A parametric design, mixer technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problems of increasing total pressure loss and thrust loss, limited adaptation space, and difficult design, and achieves a reduction in Jet mixing noise, improve jet mixing efficiency, and achieve reasonable matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the patent of the present invention clearer, the patent of the present invention will be further described in detail below in conjunction with the examples. The following examples are explanations of the patent of the present invention and the patent of the present invention is not limited to the following examples.

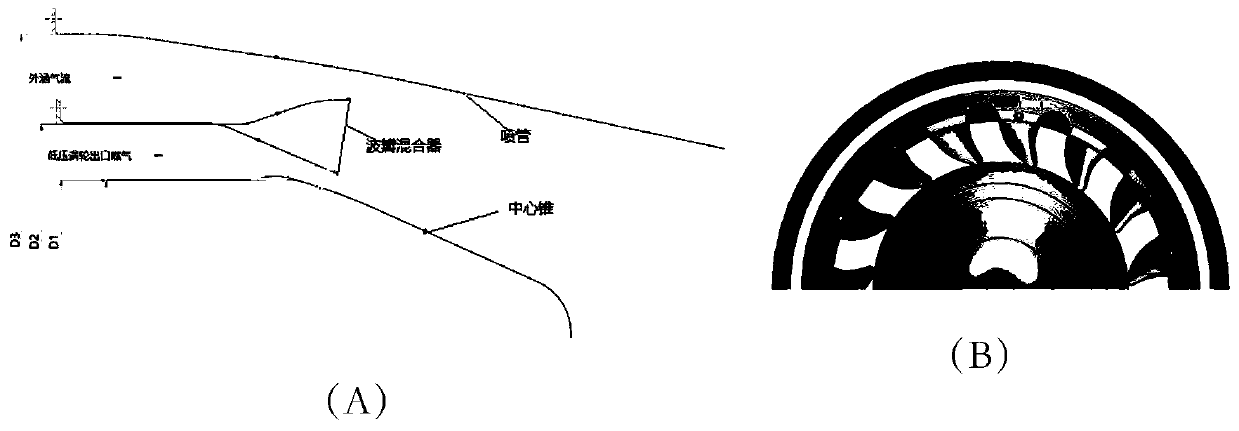

[0045] see figure 1 , The structure of the lobe mixer exhaust system that the present invention relates to mainly includes a lobe mixer, a central cone, and a mixing nozzle. The lobe mixer is used to accelerate the inner and outer airflow of the high-performance aviation gas turbofan engine, and the inner lobe of the lobe mixer mainly interacts with the outlet gas of the low-pressure turbine of the engine.

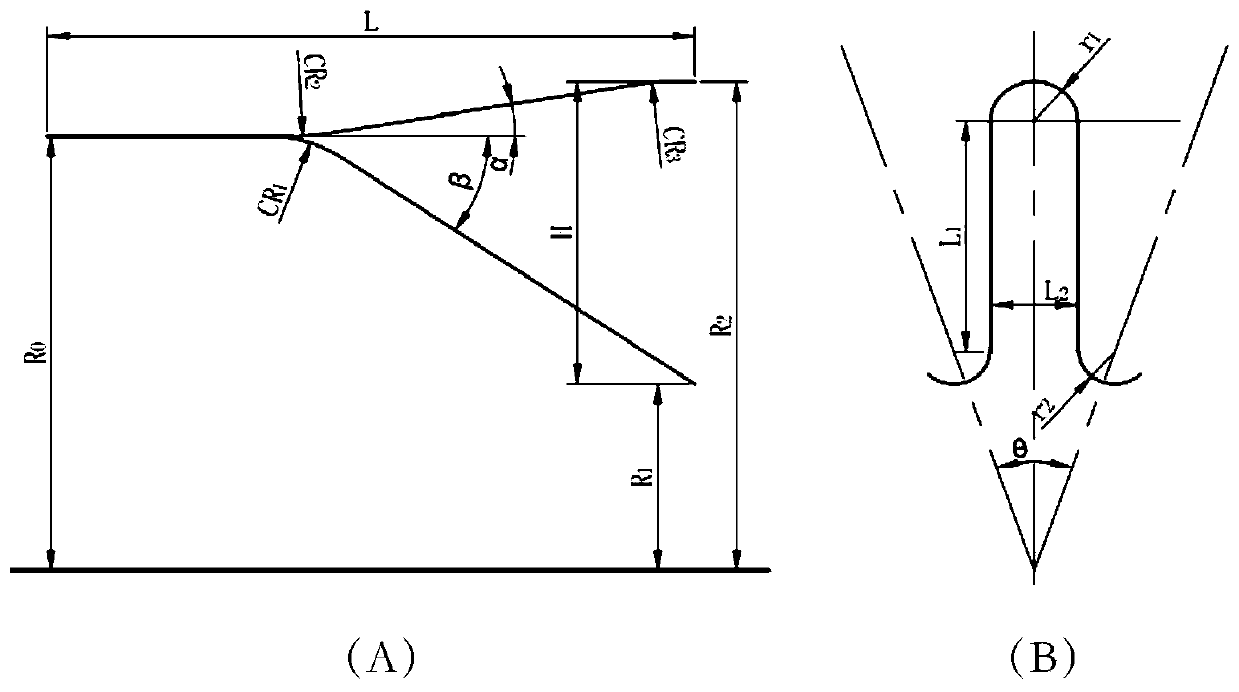

[0046] see figure 2 , the parametric modeling parameters of the conventional lobe mixer used in the present invention and the definition of each parameter, the defined parameters are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com