Control method and control system for high-voltage battery, and electric vehicle

A high-voltage battery and control method technology, applied in electric vehicles, battery circuit devices, batteries, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to an embodiment of the present invention, an embodiment of a method for controlling a high-voltage battery is provided. It should be noted that the steps shown in the flowcharts of the drawings can be executed in a computer system such as a set of computer-executable instructions, and , although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

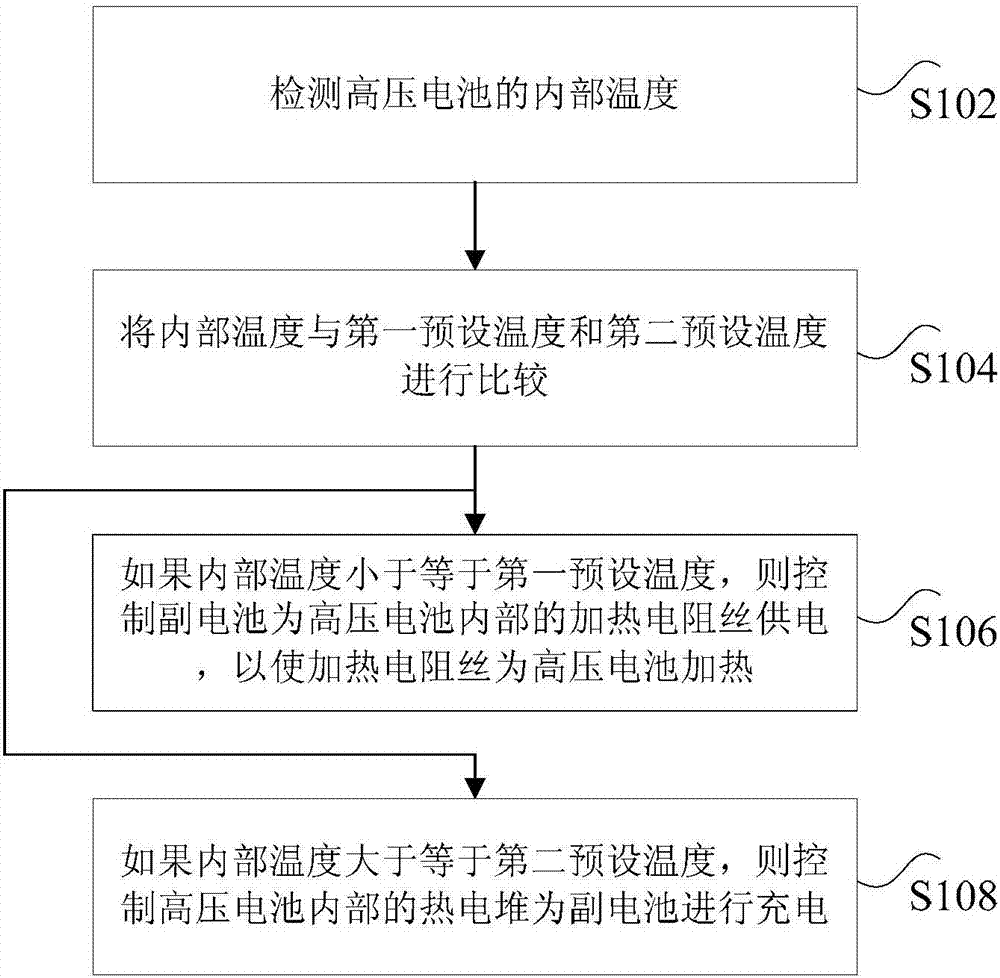

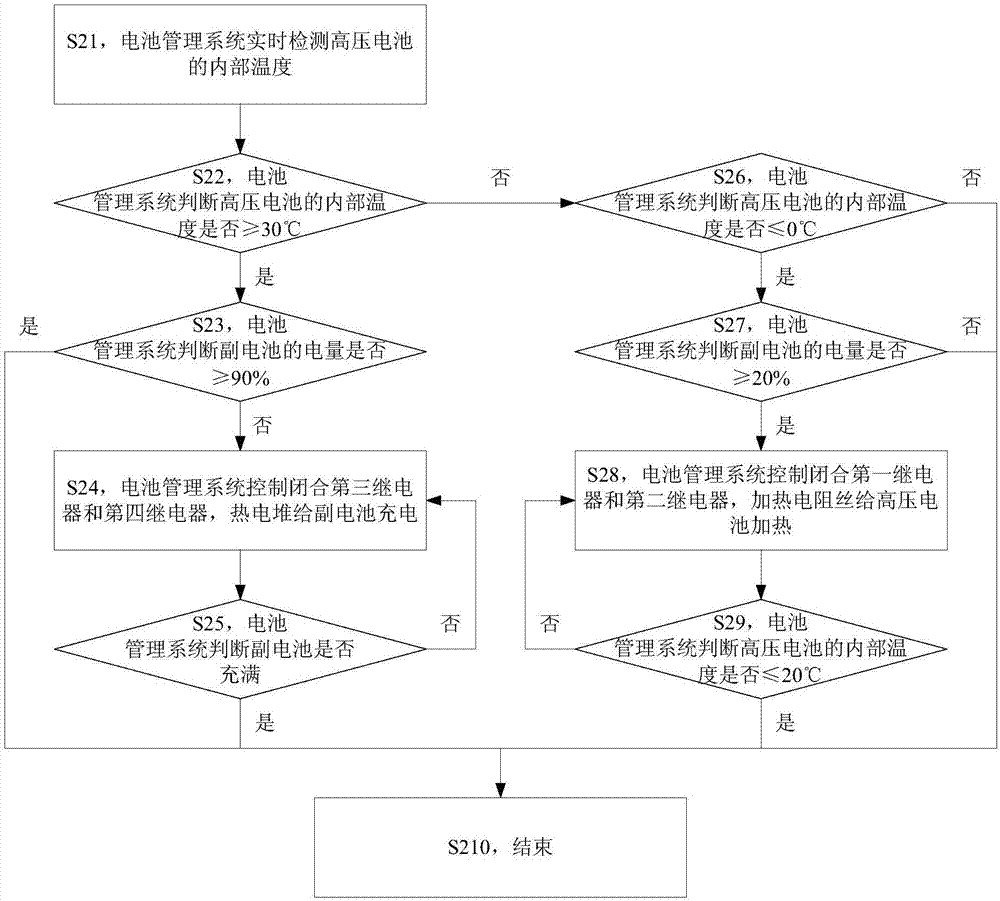

[0029] figure 1 is a flowchart of a high-voltage battery control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0030] Step S102, detecting the internal temperature of the high voltage battery.

[0031] Step S104, comparing the internal temperature with the first preset temperature and the second preset temperature.

[0032]Specifically, the above-mentioned first preset temperature may be the low temperature of the high-v...

Embodiment 2

[0083] According to an embodiment of the present invention, an embodiment of a control system for a high voltage battery is provided.

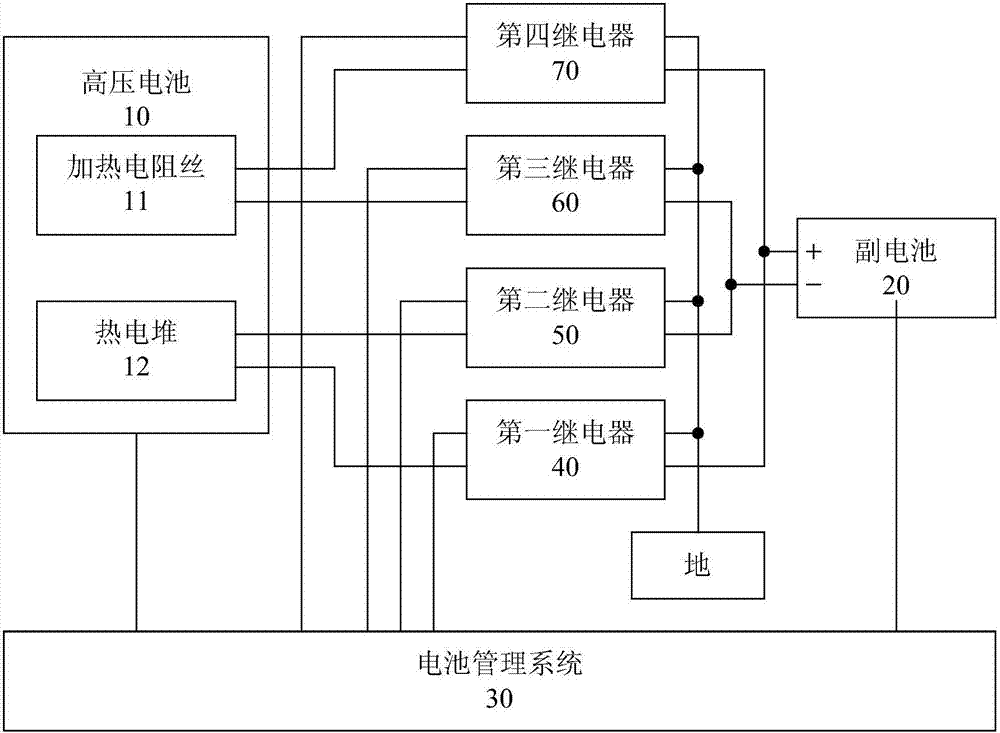

[0084] image 3 is a schematic diagram of a high-voltage battery control system according to an embodiment of the present invention, such as image 3 As shown, the system includes:

[0085] The high-voltage battery 10 is provided with a heating resistance wire 11 and a thermopile 12 inside the high-voltage battery 10 , the heating resistance wire 11 is used for heating, and the thermopile 12 is used for converting heat into electric energy.

[0086] Specifically, the heating resistance wires 11 are evenly distributed inside the high voltage battery 10 . The thermopile 12 can be composed of a plurality of parallel or series thermoelectric elements, and the thermoelectric elements can be made of practically valuable semiconductor temperature difference materials, which can convert heat energy into electric energy output power for thermoelectri...

Embodiment 3

[0113] According to an embodiment of the present invention, an embodiment of an electric vehicle is provided, including: the high-voltage battery control system in Embodiment 2.

[0114] According to the above-mentioned embodiments of the present invention, the battery management system 30 detects the internal temperature of the high-voltage battery 10, compares the internal temperature with the first preset temperature and the second preset temperature, and if the internal temperature is less than or equal to the first preset temperature, then control The auxiliary battery 20 supplies power to the heating resistance wire 11 inside the high-voltage battery 10, so that the heating resistance wire 11 heats the high-voltage battery 10. If the internal temperature is greater than or equal to the second preset temperature, the thermopile 12 inside the high-voltage battery 10 is controlled to be a secondary battery. The battery 20 is charged so that the internal temperature of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com