Alloy ingot containing magnesium cerium and preparation method

An alloy ingot and alloying technology, applied in the field of metal alloys, can solve the problems of low mold forming efficiency, poor quality, corrosion resistance, wear resistance, defective machining, etc., to achieve superior mechanical properties, good forming effect, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

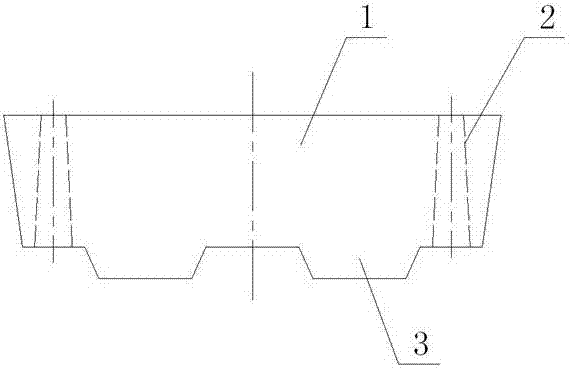

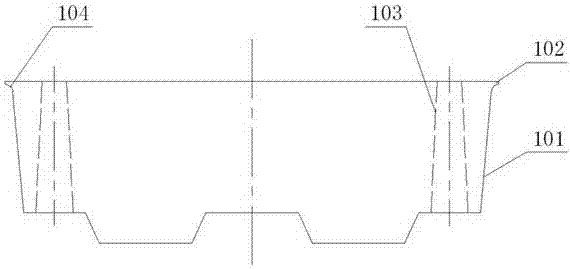

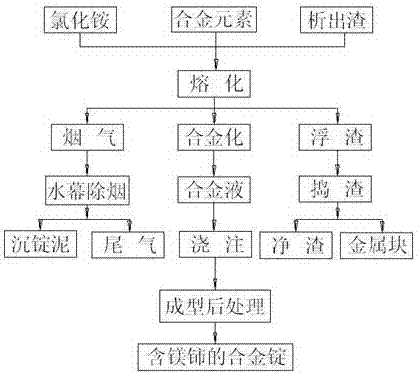

[0023] exist figure 2 , image 3 Middle: A method for preparing an alloy ingot containing magnesium and cerium, which mainly includes the following steps:

[0024] Step ①, ingredients:

[0025] An alloy ingot containing magnesium and cerium, the alloying elements are proportioned by weight percentage: 20% to 25% of aluminum, 0.2% to 0.3% of silicon, 1.1% to 1.9% of magnesium, 0.5% to 0.6% of rare earth cerium, The balance is zinc;

[0026] Step ②, smelting:

[0027] Put the proportioned metal into the smelting furnace, heat up to 650 degrees, combine magnetic stirring and manual stirring to alloy the components evenly, avoid aluminum segregation, remove scum from the inner surface of the furnace, and then take samples from the furnace mouth , whether the laboratory test ingredients are uniform;

[0028] Step ③, pouring: the pouring time should not be too fast, otherwise bubbles, slag inclusions, and cracks will easily occur. The pouring time is 3 minutes. After the pouri...

no. 1 example

[0033] A preparation method of an alloy ingot containing magnesium and cerium, mainly comprising the following steps:

[0034] Step ①, ingredients:

[0035] An alloy ingot containing magnesium and cerium, the alloying elements are proportioned by weight percentage: aluminum 20%, silicon 0.2%, magnesium 1.1%, rare earth cerium 0.5%, and the balance is zinc;

[0036] Step ②, smelting:

[0037] Put the proportioned metal into the smelting furnace, heat up to 650 degrees, combine magnetic stirring and manual stirring to alloy the components evenly, avoid aluminum segregation, remove scum from the inner surface of the furnace, and then take samples from the furnace mouth , whether the laboratory test ingredients are uniform;

[0038] Step ③, pouring: use a movable zinc chute for pouring; the pouring time should not be too fast, otherwise bubbles, slag inclusions, and cracks will easily occur. The pouring time is 3 minutes. After the pouring is completed, remove the slag on the su...

no. 2 example

[0042] A preparation method of an alloy ingot containing magnesium and cerium, mainly comprising the following steps:

[0043] Step ①, ingredients:

[0044] An alloy ingot containing magnesium and cerium, the alloying elements are proportioned by weight percentage: aluminum 22%, silicon 0.22%, magnesium 1.3%, rare earth cerium 0.52%, and the balance is zinc;

[0045] Step ②, smelting:

[0046] Put the proportioned metal into the smelting furnace, heat up to 650 degrees, combine magnetic stirring and manual stirring to alloy the components evenly, avoid aluminum segregation, remove scum from the inner surface of the furnace, and then take samples from the furnace mouth , whether the laboratory test ingredients are uniform;

[0047] Step ③, pouring: use a movable zinc chute for pouring; the pouring time should not be too fast, otherwise bubbles, slag inclusions, and cracks will easily occur. The pouring time is 3 minutes. After the pouring is completed, remove the slag on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com