Experimental device and method thereof for physical simulation of natural fractures with pre-set media

A technology of natural fractures and physical simulation, applied in teaching models, earthwork drilling, mining fluids, etc., can solve the problems of inability to simulate the sealing environment of natural fractures, inability to accurately meet, inability to simulate extension, etc., to achieve diversity and operation The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

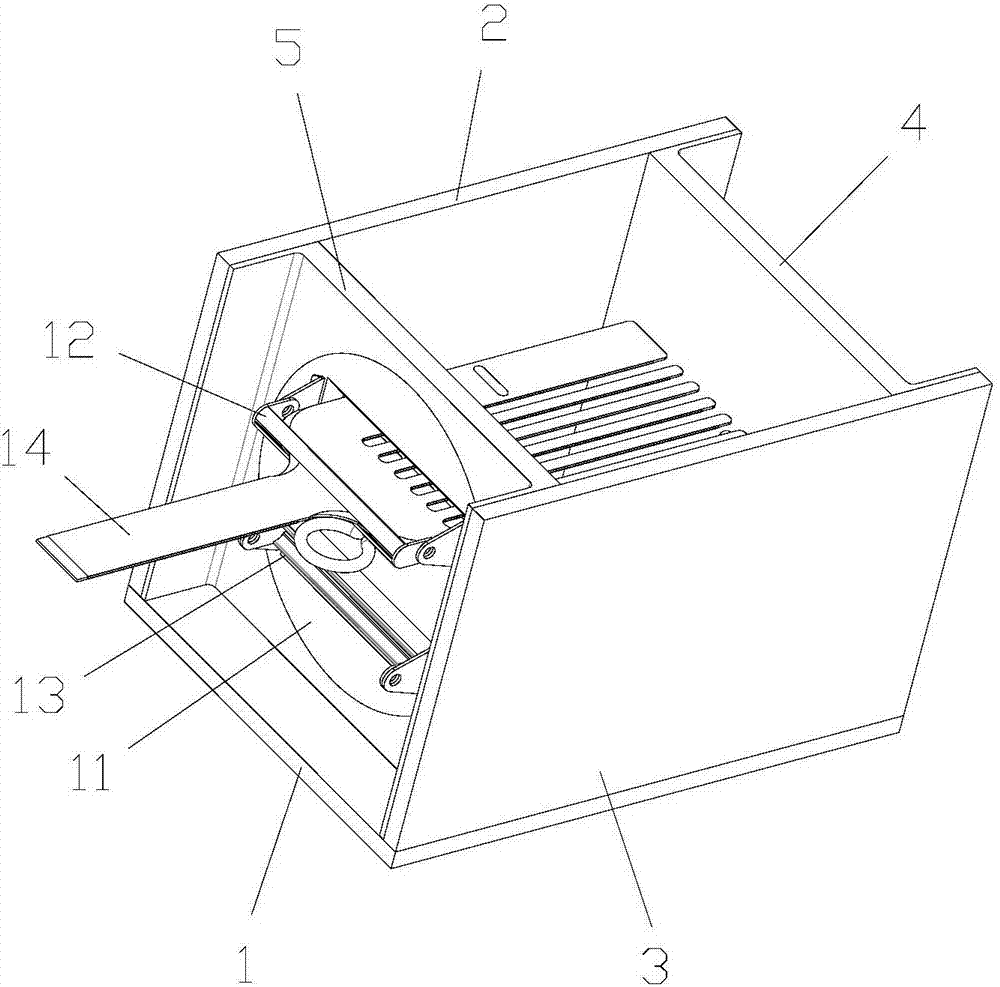

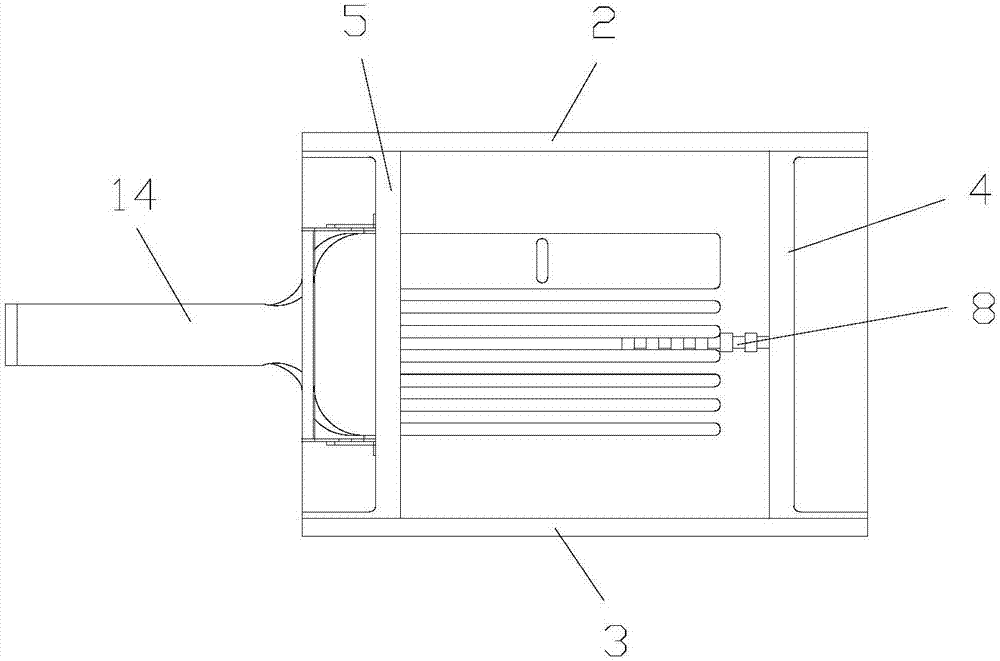

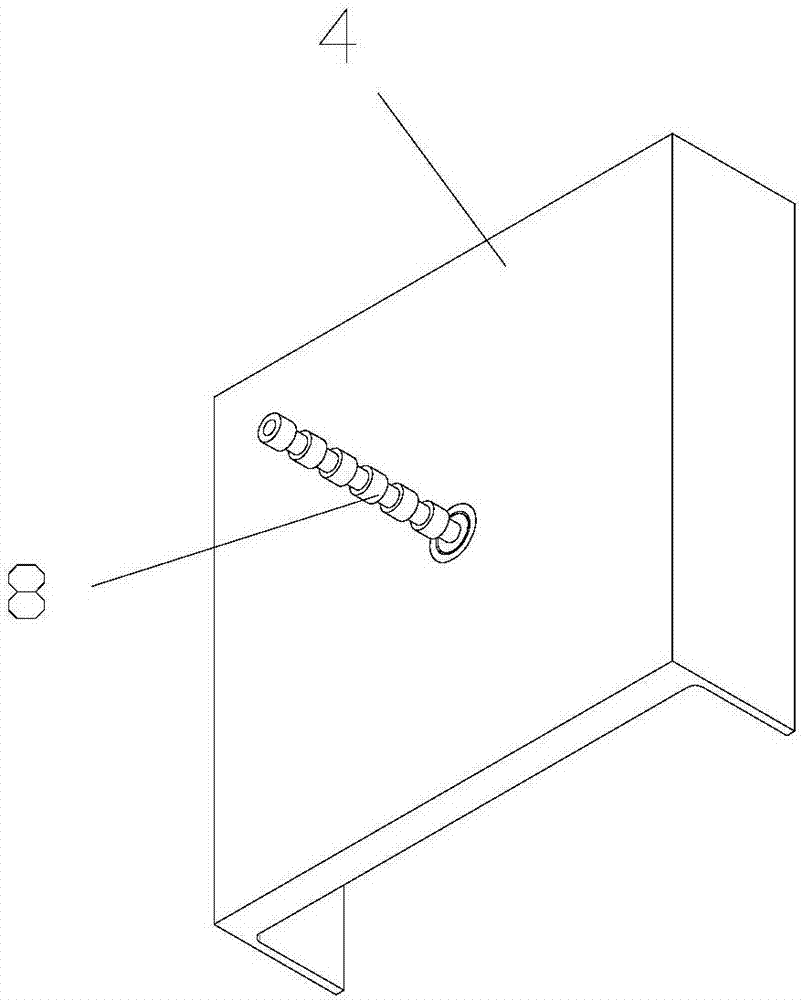

[0059] Such as Figure 1-12 As shown, according to the physical simulation experiment device of the natural fracture with medium preset in the present invention, the core pouring tank is assembled from the bottom plate 1, the side plate I2, the side plate II3, the wellbore side plate 4 and the seam loading side plate 5; The plate I2 and the side plate II3 are symmetrically arranged on the bottom plate 1, and the wellbore side plate 4 and the seam side plate 5 are symmetrically arranged on the bottom plate 1; the central part of the wellbore side plate 4 is opened Wellbore limit hole 6, rubber ring 7 and wellbore 8 are installed in the wellbore limit hole 6; a disc limit hole 9 is set in the center of the seam-loading side plate 5, and a disc limit hole 9 is installed in the disc limit hole 9. As for the seam fitting assembly, two protrusions 10 are arranged symmetrically on the circumference of the disk limit hole 9; Reed piece 15, limit groove 24 and spacer groove 25 are set...

Embodiment 2

[0081] According to another embodiment of the physical simulation experiment device and the method thereof of the natural fracture preset with the medium of the present invention, the structure of the experimental device, the connection relationship between each part, the experimental procedure, the working principle and the beneficial effect etc. are all consistent with the implementation Example 1 is the same, the difference is:

[0082] The width of slot I formed by the bottoms of the two wedge-shaped planes of the wedge-shaped slot is 3 mm; the width of slot II on the recliner is 3 mm. The rotation angle of the seaming disc is 90°, that is, the angle formed by the seam inserting plate and the side plate I or side plate II is 90°. The angle formed between the two wedge-shaped planes of the wedge-shaped slot is α=100º; the angle formed between the slotting plate and the wellbore is β, 0º≤β≤50º.

Embodiment 3

[0084] According to another embodiment of the physical simulation experiment device and the method thereof of the natural fracture preset with the medium of the present invention, the structure of the experimental device, the connection relationship between each part, the experimental procedure, the working principle and the beneficial effect etc. are all consistent with the implementation Example 1 is the same, the difference is:

[0085] The width of slot I formed by the bottoms of the two wedge-shaped planes of the wedge-shaped slot is 5 mm; the width of slot II on the recliner is 5 mm. The rotation angle of the seaming disc is 120°, that is, the angle formed by the seam inserting plate and the side plate I or side plate II is 120°. The angle formed between the two wedge-shaped planes of the wedge-shaped slot is α=120º; the angle formed between the slotting insert and the wellbore is β, 0º≤β≤60º.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com