Power multi-branch hydraulic planetary speed regulating device

A speed regulating device and multi-branch technology, applied in transmission devices, transmission parts, fluid transmission devices, etc., can solve problems such as difficulty in ensuring comprehensive and efficient operation, and achieve the effects of flexible design, weight reduction, and convenient selection and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

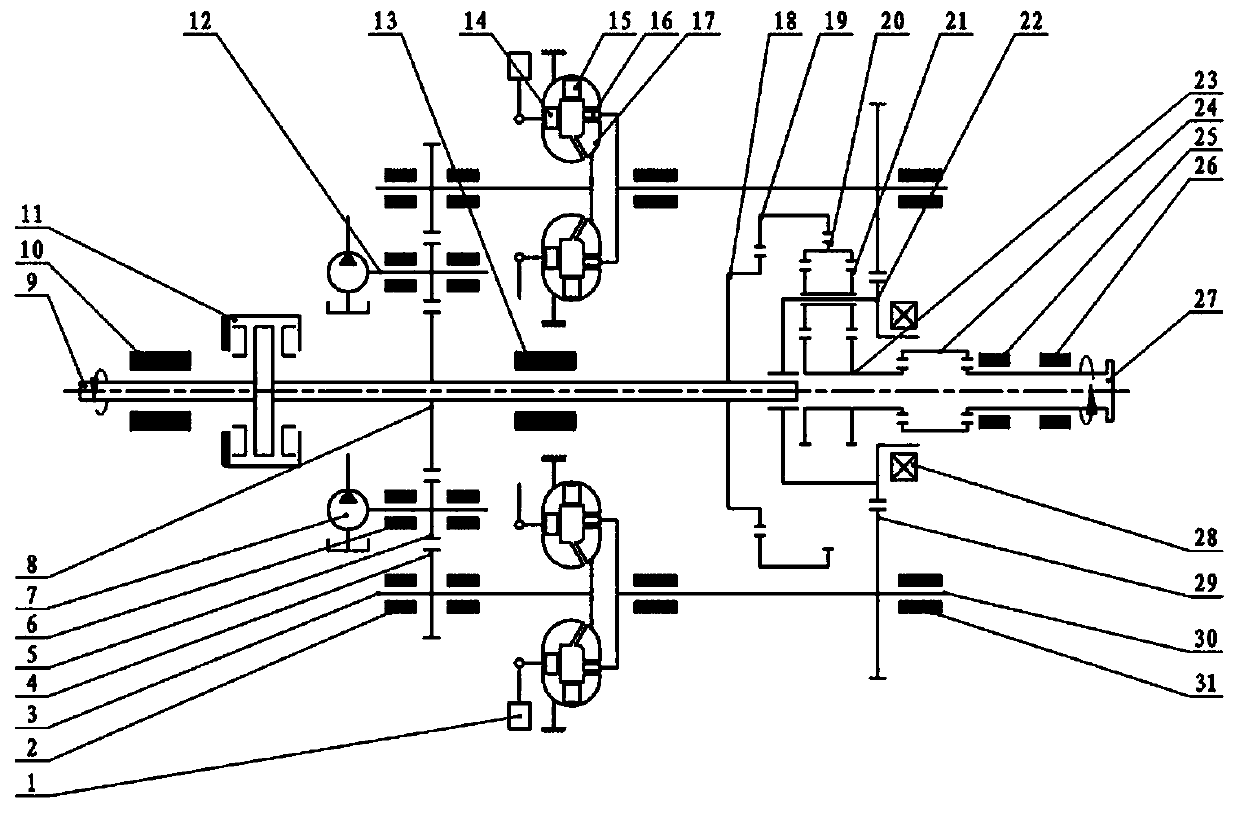

[0021] refer to figure 1 , a power multi-branch hydraulic planetary speed regulating device, including an actuator 1, a power split low-speed shaft 3, a power split input shaft 30 and an input shaft 9, the outer wall of one end of the input shaft 9 is sleeved with a second sliding bearing 10, the second sliding A thrust bearing 11 is provided on the right side of the bearing 10, and a gear 8 is provided on the outer wall of the input shaft 9 on the right side of the thrust bearing 11. The gear 8 is connected with the belt pump gear 5, and the belt pump gear 5 is connected to the machine through the second belt pump gear 12. The belt pump 7 is connected, the second belt pump gear 12 is connected with the first sliding bearing 6, the belt pump gear 5 is connected with the power split low-speed gear 4, the power split low-speed gear 4 is arranged on the power split low-speed shaft 3, and the power split low-speed The end of the shaft 3 is provided with a rolling bearing 2, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com