Gas multipurpose fuel boiler

A boiler and fuel technology, applied in the field of boilers, can solve the problems of high nitrogen oxide emissions, insufficient combustion chamber volume, difficult maintenance, etc., and achieve the effects of low emission of harmful substances, convenient production and no maintenance dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

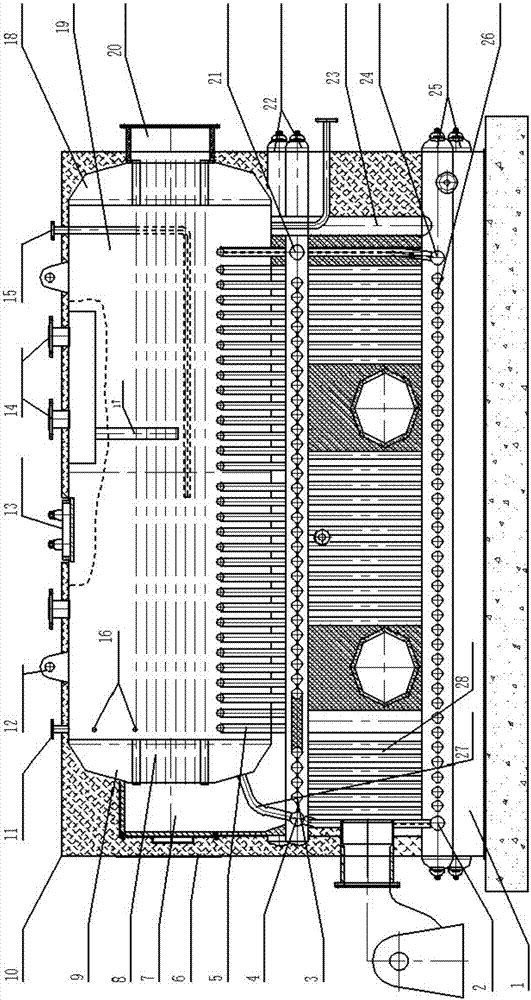

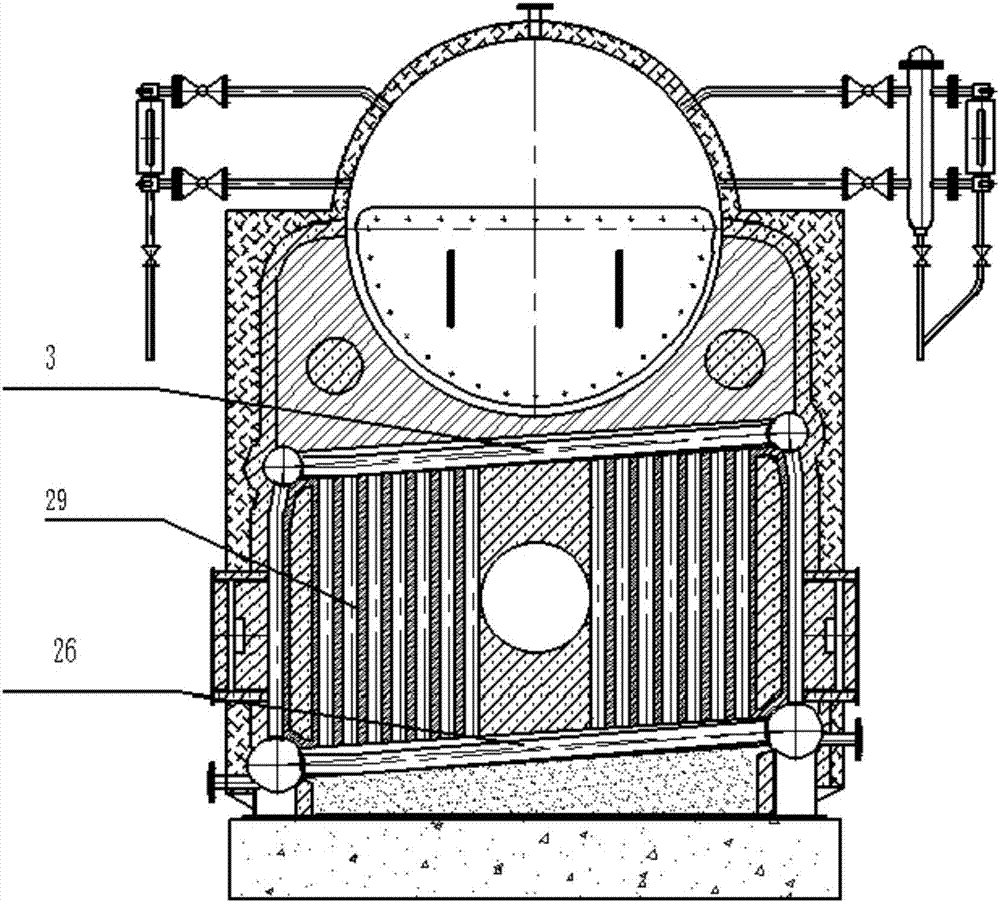

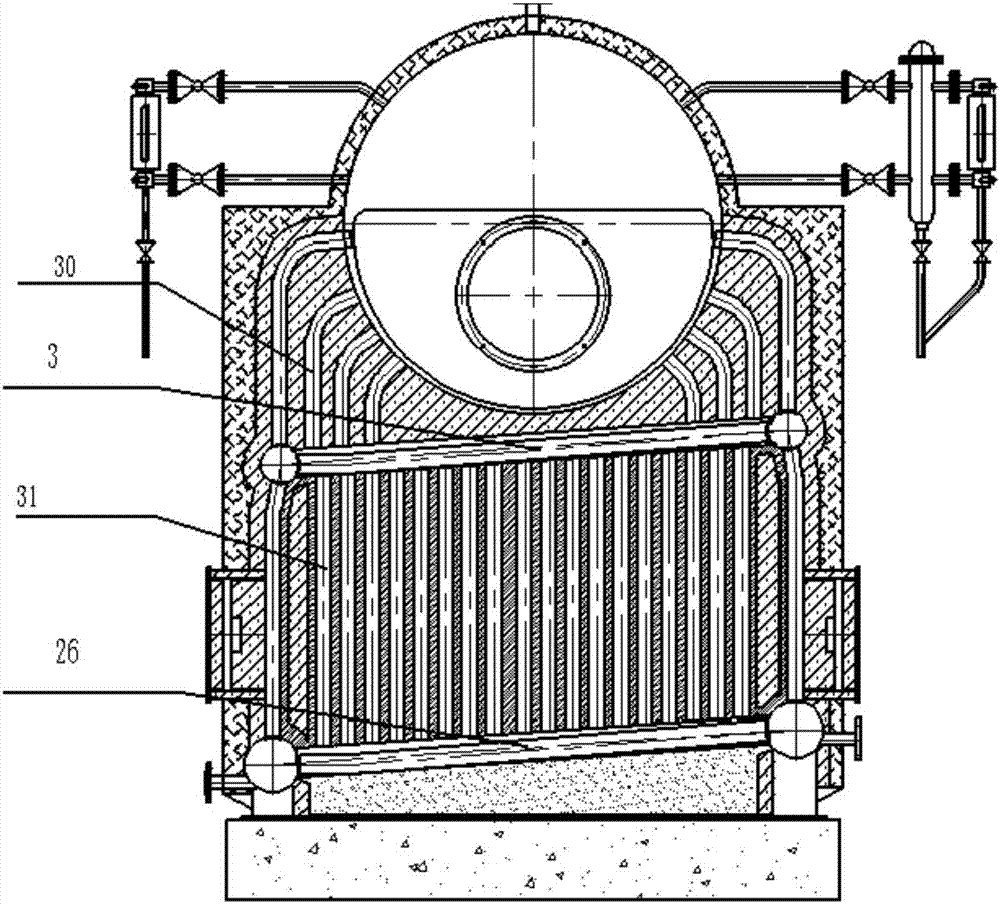

[0035] A gas multi-fuel boiler, including a drum and a combustion chamber, a burner interface is provided on the front of the combustion chamber, and a maintenance port is provided on the side wall of the combustion chamber.

[0036] The drum includes a middle drum body, a front tube sheet and a rear tube sheet are respectively arranged at the front and rear ends of the middle drum body, and several drum inner tubes connecting the front tube sheet and the rear tube sheet are arranged in the drum. Smoke pipe, the inner smoke pipe constitutes a three-pass flue;

[0037] There is a front smoke box in front of the front tube plate, and a rear smoke outlet in the rear of the rear tube plate.

[0038] The combustion chamber includes lower left longitudinal header pipes, lower rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com