Segregation distribution method for sintered material

A technology of segregating cloth and sintering materials, which is applied in the field of sintering, can solve the problems of sintering machines that are difficult to achieve lateral segregation, and achieve the effect of improving the quality of sintered products and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

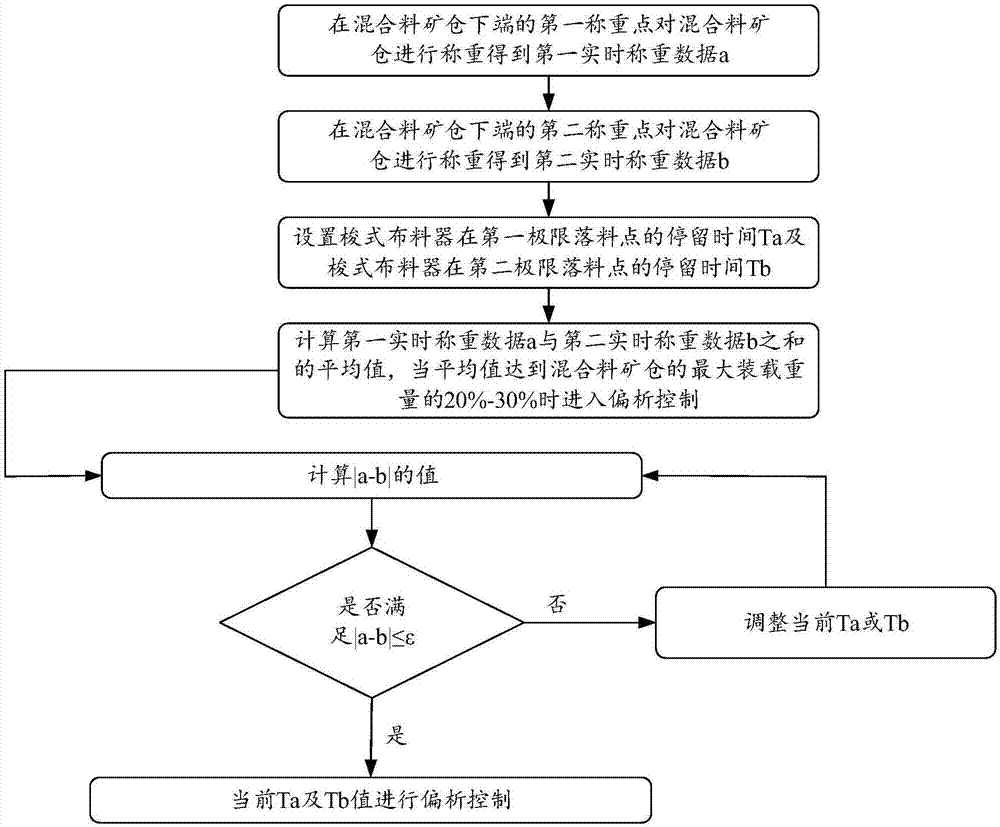

[0025] The embodiment of the present invention solves the technical problem that the sintering machine is difficult to achieve good lateral segregation in the prior art by providing a sintered material segregation distribution method, and realizes the lateral segregation of the sintered material, so that the sintered material with a large particle size is distributed in the mixed material In the middle of the sintering pile in the ore bin, the air permeability in the middle of the sintering pile is improved, so that the sintering material is evenly sintered and the quality of the sintered product is improved.

[0026] see figure 1 , the embodiment of the present invention provides a sintered material segregation distribution method, comprising:

[0027] The first weighing point at the lower end of the mixed material silo weighs the mixed material silo to obtain the first real-time weighing data a, and the first weighing point corresponds to the first limit material drop point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com