Sintering machine grate anti-paste and anti-block method

A technology of sintering machine and machine grate bar, applied in the field of sintering, can solve the problem of easy clogging of grate bar of sintering machine, and achieve the effects of reducing the passing grate bar, inhibiting grate bar sticking and reducing dust content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

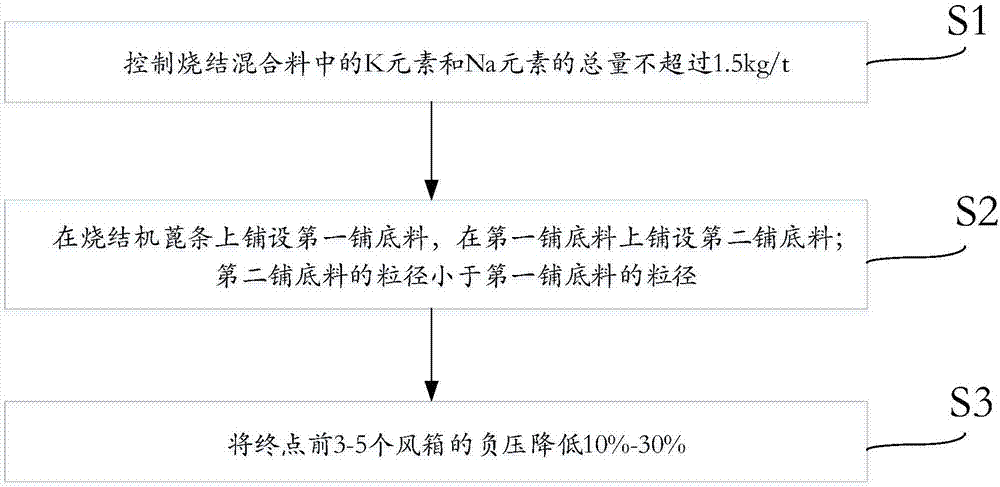

Method used

Image

Examples

Embodiment 1

[0036] In practical applications, when a sintering production line is in production, the specific implementation is as follows:

[0037] The chemical composition of each sintering raw material was tested to obtain the contents of K and Na elements in each sintering raw material, and the total amount of K and Na elements in the sintering mixture was controlled to be 1.0kg / t.

[0038] Adding a bulkhead in the first bottom bunker separates the first bottom bunker into a front bin and a rear bin. Assemble the first primer in the front warehouse, the first primer is sintered ore; the particle size of the first primer is 12-20mm; assemble the second primer in the rear warehouse, the second primer is sintered ore; the second The particle size of the bottom layer is 5-12mm. Lay the first primer on the grating bar of the sintering machine before opening the warehouse, and control the laying thickness of the first primer to be 50mm; after opening, lay the second primer on the first pri...

Embodiment 2

[0041] In practical applications, when a sintering production line is in production, the specific implementation is as follows:

[0042] The chemical composition of each sintering raw material was tested to obtain the contents of K and Na elements in each sintering raw material, and the total amount of K and Na elements in the sintering mixture was controlled to be 1.5kg / t.

[0043] Add a second bottoming silo behind the first bottoming silo, transport the first bottoming material with a particle size of 12-30mm to the first bottoming silo, and transport the second bottoming material with a particle size of 5-12mm to the second Bottom silo.

[0044] Lay the first bottoming material on the sintering machine grate bar before opening the warehouse, the first bottoming material is sintering ore; control the laying thickness of the first bottoming material to 40mm; after opening, lay the second bottoming material on the first bottoming material, the second bottoming material The s...

Embodiment 3

[0047] In practical applications, when a sintering production line is in production, the specific implementation is as follows:

[0048] The chemical composition of each sintering raw material was tested to obtain the contents of K and Na elements in each sintering raw material, and the total amount of K and Na elements in the sintering mixture was controlled to be 1.5kg / t.

[0049] Adding a bulkhead in the first bottom bunker separates the first bottom bunker into a front bin and a rear bin. Assemble the first primer in the front warehouse, the first primer is sintered ore; the particle size of the first primer is 12-20mm; assemble the second primer in the rear warehouse, the first primer is sintered ore; the second The particle size of the bottom layer is 5-12mm. Lay the first bottoming material on the sintering machine grate bar before opening the warehouse, the first bottoming material is sintering ore; control the laying thickness of the first bottoming material to 50mm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com