Weld seam corrosion monitoring device and monitoring method capable of simulating stressed state

A welding seam corrosion and monitoring device technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of less devices and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

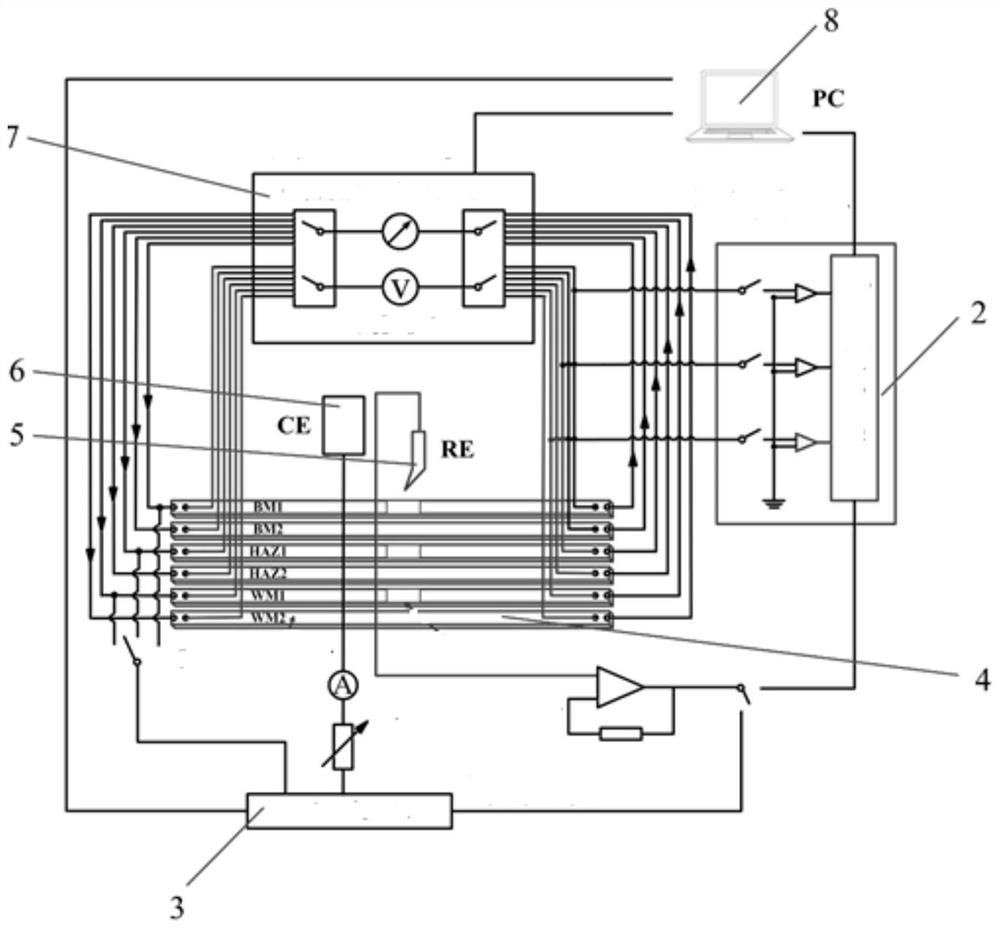

[0033] At present, the laboratory research on weld corrosion mainly adopts electrochemical methods. Electrochemical methods such as potential measurement, linear polarization, and AC impedance measurement are simple to operate, but the method needs to ensure that the experimental environment is an electrolyte environment, and the fluid transported inside the actual oil and gas pipelines and other structures is basically non-electrolyte, so electrochemical methods are used. The online corrosion monitoring method has limitations. The resistance probe is suitable for various corrosive medium environments, and the collected data is relatively stable and reliable.

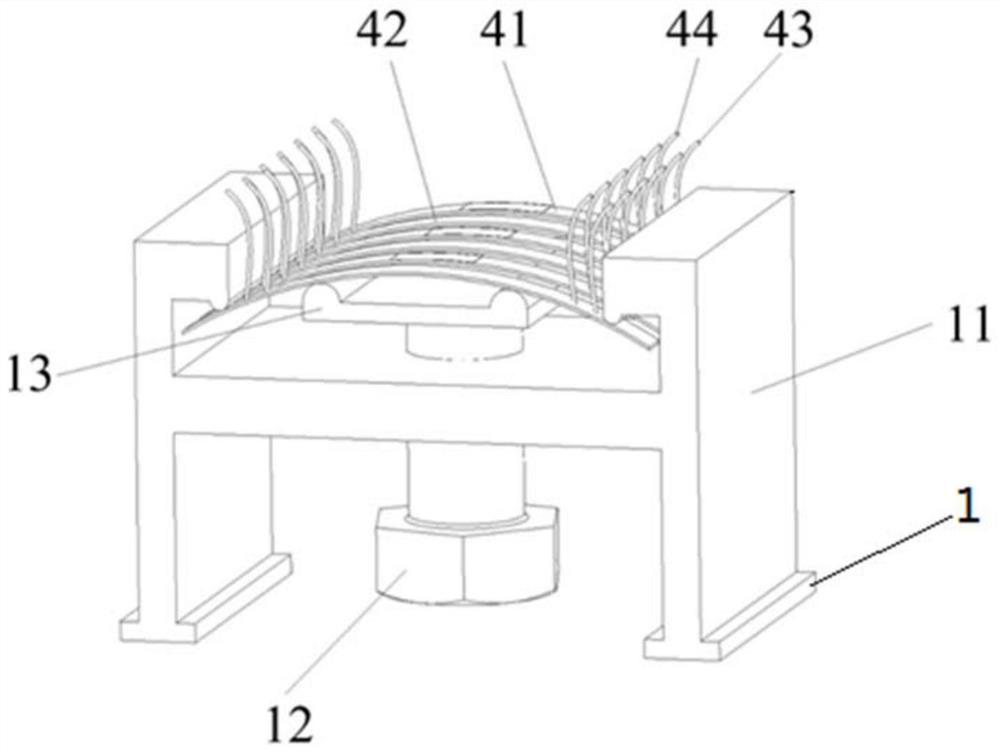

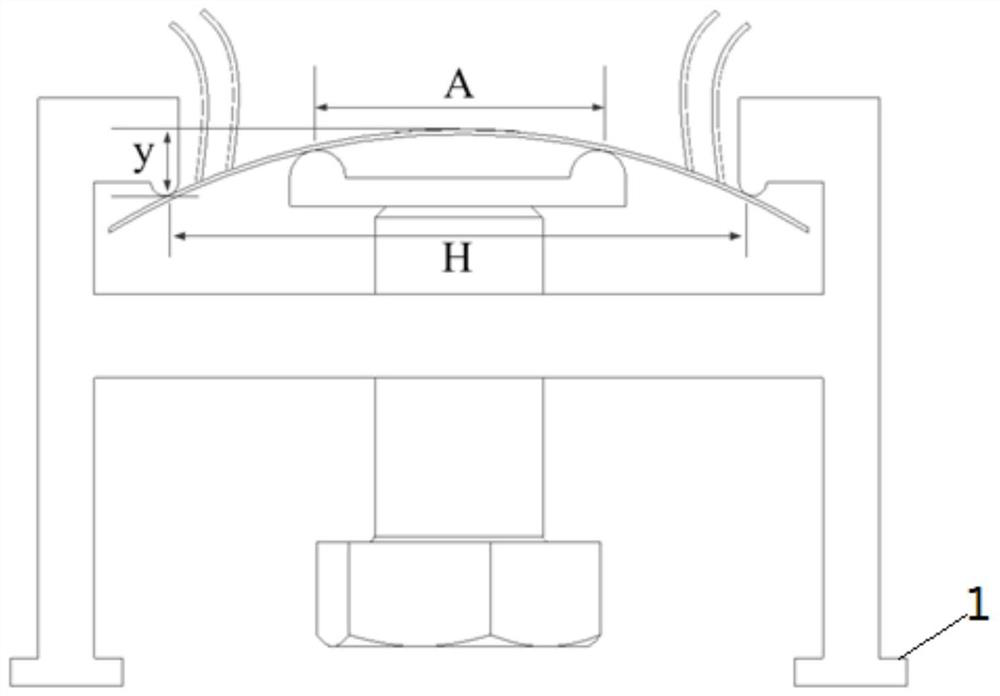

[0034] The weld is a complex structure, and the main form of corrosion is localized corrosion. Therefore, the traditional laboratory methods cannot obtain the local corrosion information of the welded seam structure. For the welded seam structure, research and analysis of different areas: base metal area, thermal The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com