A kind of tubular ultra-miniature fuse manufacturing tool and manufacturing method

A technology for making tools and fuses, which is applied in the manufacture of fuses, etc. It can solve problems such as poor fusing performance, inability to pour quartz sand, and inability to make fuses, etc., to achieve the effect of expanding the actual application environment and improving the consistency of fusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

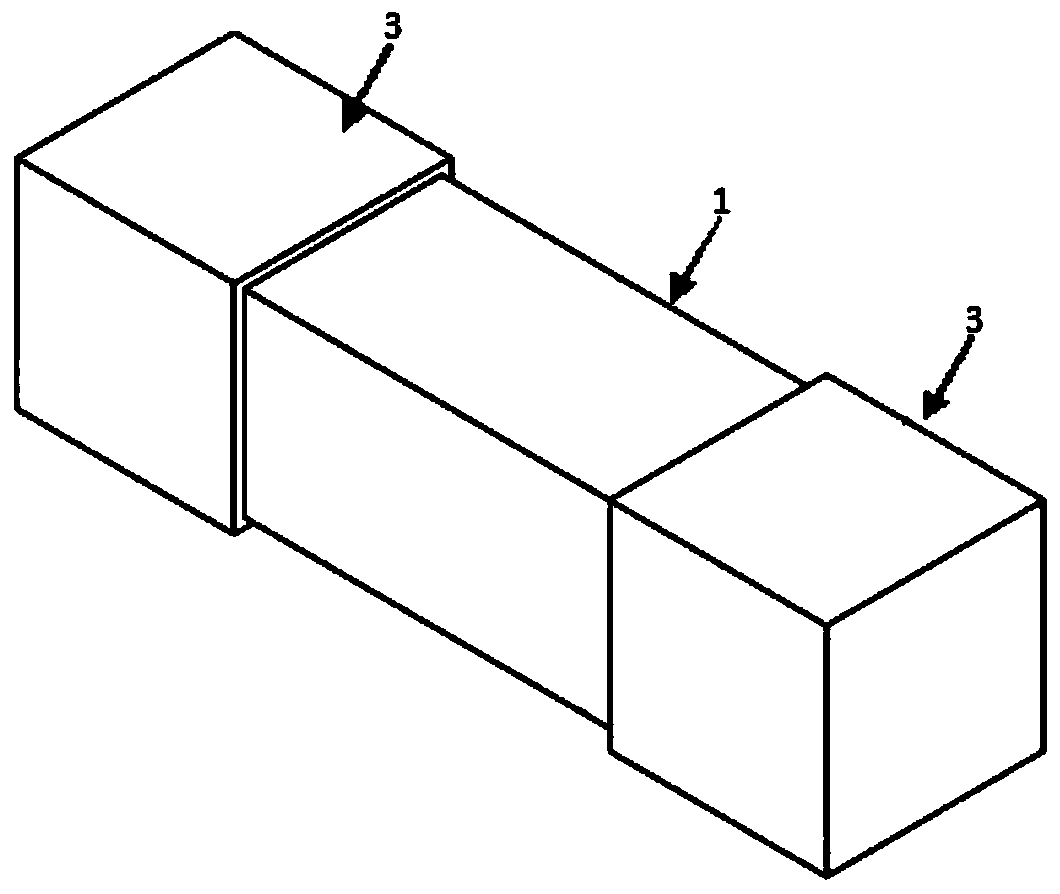

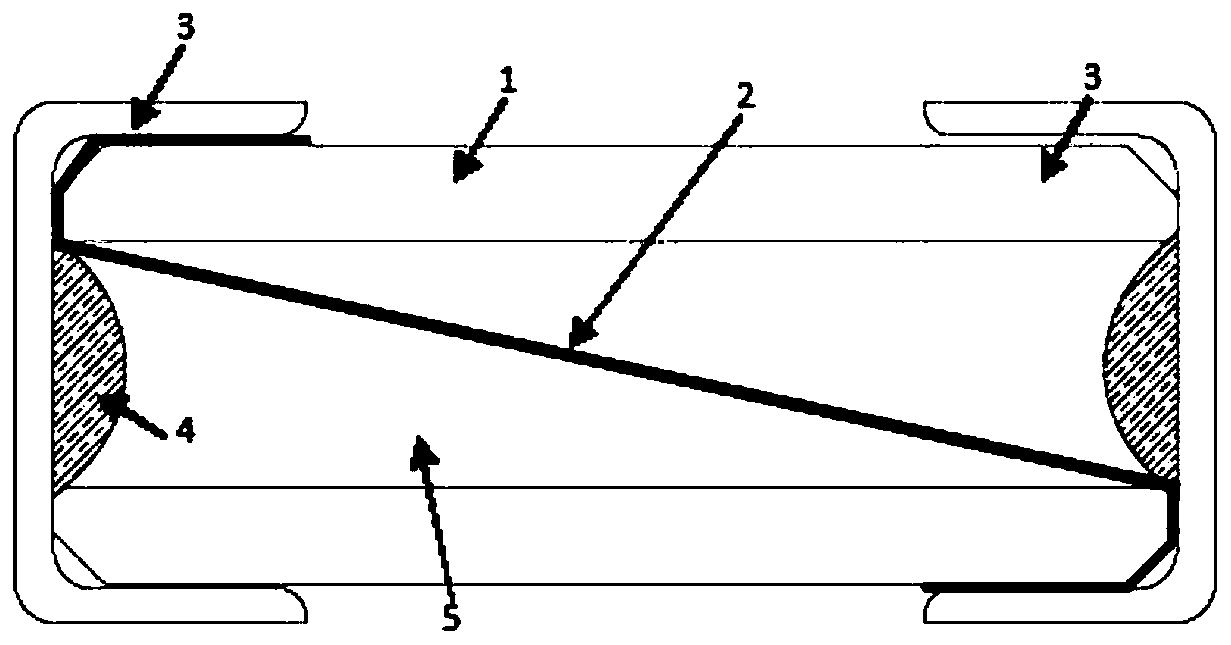

[0040] like figure 1 Shown is a three-dimensional schematic diagram of a ceramic tube structure ultra-miniature fuse in the present invention, figure 2 for its cross-section. The metal melt 2 passes through the interior of the ceramic tube 1 and is electrically connected with the end caps 3 at both ends with metal solder 4. The interior of the ceramic tube 1 is filled with an arc-extinguishing material 5 to improve the fusing characteristics and breaking capacity of the product.

[0041] The arc extinguishing material 5 is to use liquid silica gel or melamine formaldehyde resin as a dispersion solvent, add at least one of melamine resin powder, magnesium hydroxide flame retardant, aluminum hydroxide flame retardant, or fumed silica powder, to improve The arc-quenching properties of the material, increasing the slurry viscosity and / or reducing the thermal conductivity of the slurry.

[0042] Further, the formula of the arc extinguishing material 5 slurry is 1:0.03-0.2 (wt%),...

Embodiment 2

[0045]The manufacturing method of ceramic tube structure ultra-miniature fuse of the present invention comprises the following steps:

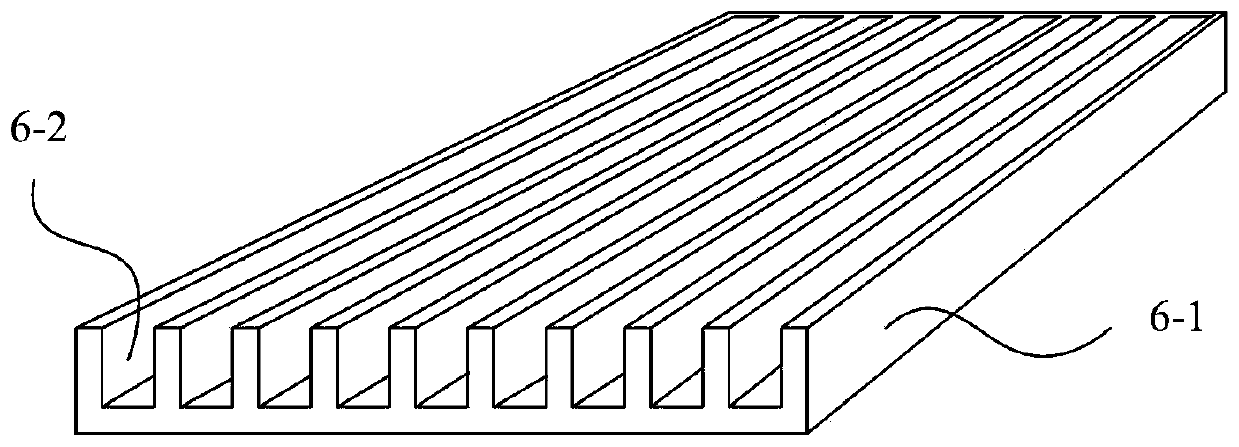

[0046] 1) Porcelain tube threading: first put the ceramic tube 1 on a special jig (such as image 3 ), and then pass the required metal melt 2 sequentially through each row of ceramic tubes 1 by means of threading needles to obtain a series of ceramic tubes; image 3 The porcelain row jig described is a jig with one end made of wear-resistant materials such as metal, which is opened to the edge of the jig, with a width equal to the width of the ceramic tube and a thickness equal to the thickness of the ceramic tube. The purpose is to facilitate mass production of products. The operation of piercing molten metal 2.

[0047] 2) Porcelain tube winding: the porcelain tube string obtained in 1) is neatly wound on the tube winding jig bar, so that the ceramic tubes 1 are arranged sequentially on both sides of the jig bar, and fixed by the metal mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com