An IGBT structure with an inverted stand surface and a method for manufacturing the same

A fabrication method and substrate surface technology, which can be used in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problem of inability to maintain the threshold voltage of the gate set parasitic capacitance, and achieve the goal of maintaining the threshold voltage unchanged and reducing the gate voltage. The effect of collecting parasitic capacitance and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

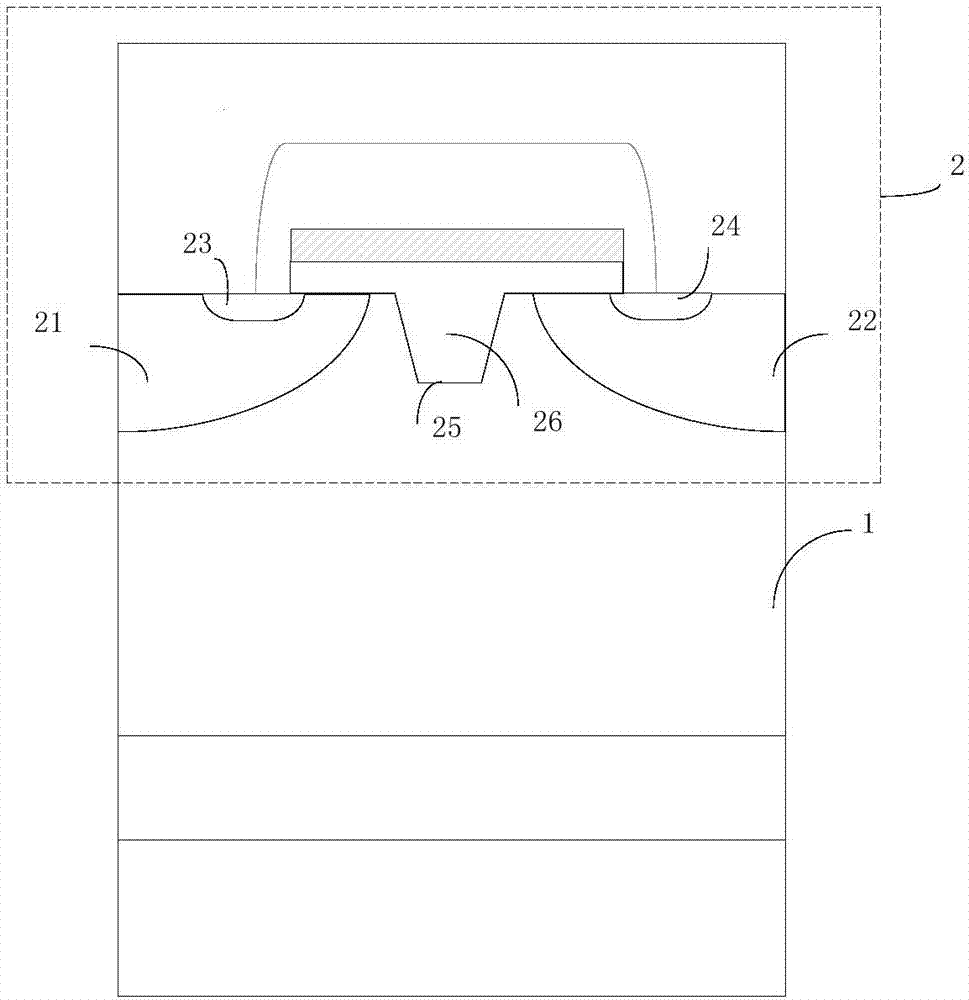

[0039] figure 2 A schematic structural diagram of an inverted mesa gate IGBT structure provided for Embodiment 1 of the present invention; figure 2 As shown, this embodiment provides an inverted mesa gate IGBT structure, including:

[0040] The semiconductor substrate 1 and the cellular region 2; the cellular region 2 includes a first base region 21 located in the surface of the semiconductor substrate 1, a second base region 22, a first source region 23 located in the first base region 21, and a first source region located in the surface of the semiconductor substrate 1. The second source region 24 in the second base region 22 and the inverted mesa 25 between the first base region 21 and the second base region 22, the inverted mesa 25 is a structure with a wide top and a narrow bottom, and the lower part of the inverted mesa 25 is located on the semiconductor substrate 1, the upper part is flush with the surface of the semiconductor substrate 1, the surface of the semicond...

Embodiment 2

[0046] This embodiment is a supplementary description based on the above embodiments.

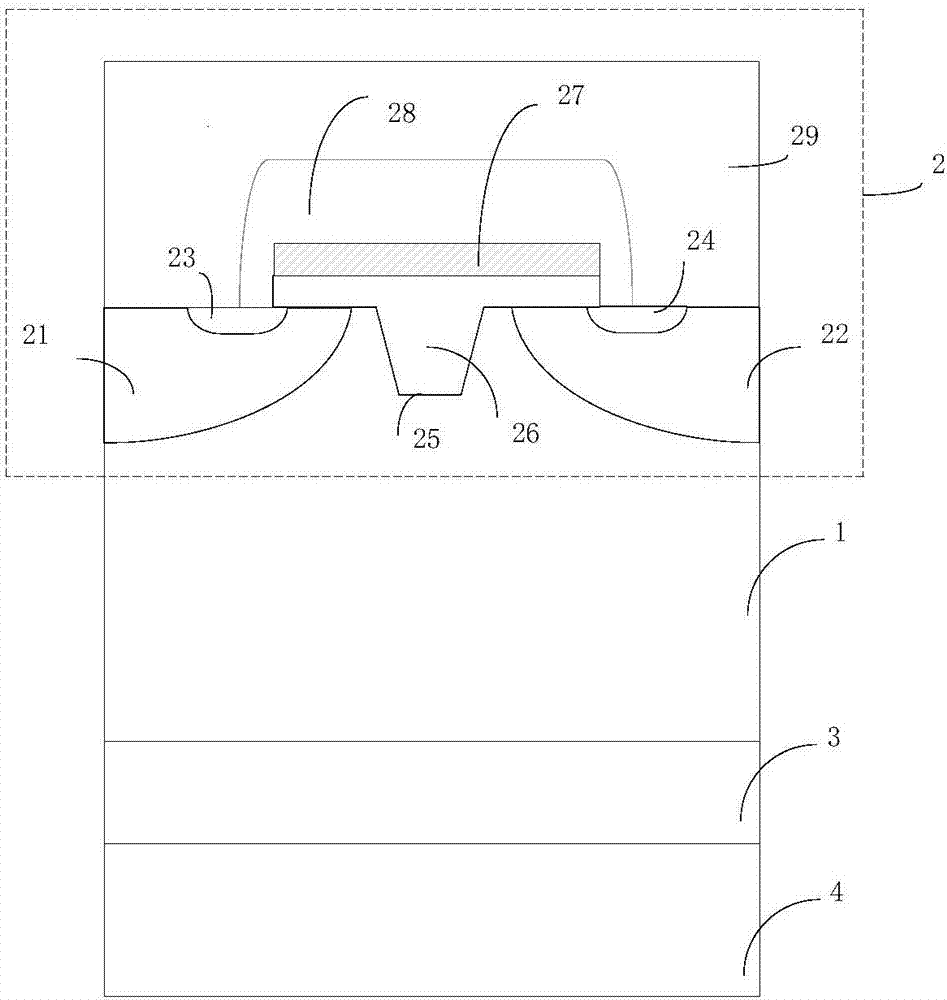

[0047] image 3 A schematic structural diagram of an inverted mesa gate IGBT structure provided for Embodiment 1 of the present invention; image 3 As shown, the cell region 2 further includes a polysilicon layer 27 covering the oxide layer 26 .

[0048] Further, the cell region 2 also includes a passivation layer 28 and a first metal layer 29, wherein the passivation layer 28 covers the polysilicon layer 27, part of the first source region 23 and part of the second source region 24, and the first metal layer 29 Covering the passivation layer 28 , part of the first source region 23 , part of the second source region 24 , part of the first base region 21 and part of the second base region 22 .

[0049] Specifically, the passivation layer 28 is used to separate the first metal layer 29 from the oxide layer 26 and the polysilicon layer 27, and the first metal layer 29 is preferably an alumin...

Embodiment 3

[0056] The manufacturing method of the inverted mesa gate IGBT provided in this embodiment is used to manufacture the inverted mesa gate IGBT structure in the first embodiment above.

[0057] Figure 4 A schematic flow chart of the manufacturing method of the inverted mesa gate IGBT provided in Embodiment 3 of the present invention; as Figure 4 As shown; this embodiment provides a method for manufacturing an inverted mesa gate IGBT, including:

[0058] Step 101, forming an inverted mesa structure in the surface of the semiconductor substrate, the inverted mesa structure is filled with an oxide layer, wherein the inverted mesa structure is wide at the top and narrow at the bottom, the lower part of the inverted mesa is located in the semiconductor substrate, and the upper part is flush with the surface of the semiconductor substrate together.

[0059] The structure formed in this step is as Figure 5 As shown, numeral 400 is a semiconductor substrate, and numeral 401 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com