Method for eliminating swelling of soft-packing lithium ion battery

An ion battery, soft-packed lithium technology, used in secondary battery gas removal, electrical components, secondary batteries, etc., can solve the problems of unstable film formation, and it is difficult to eliminate flatulence due to flatulence, so as to improve battery stability and eliminate battery. Flatulence, simple and effective battery flatulence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

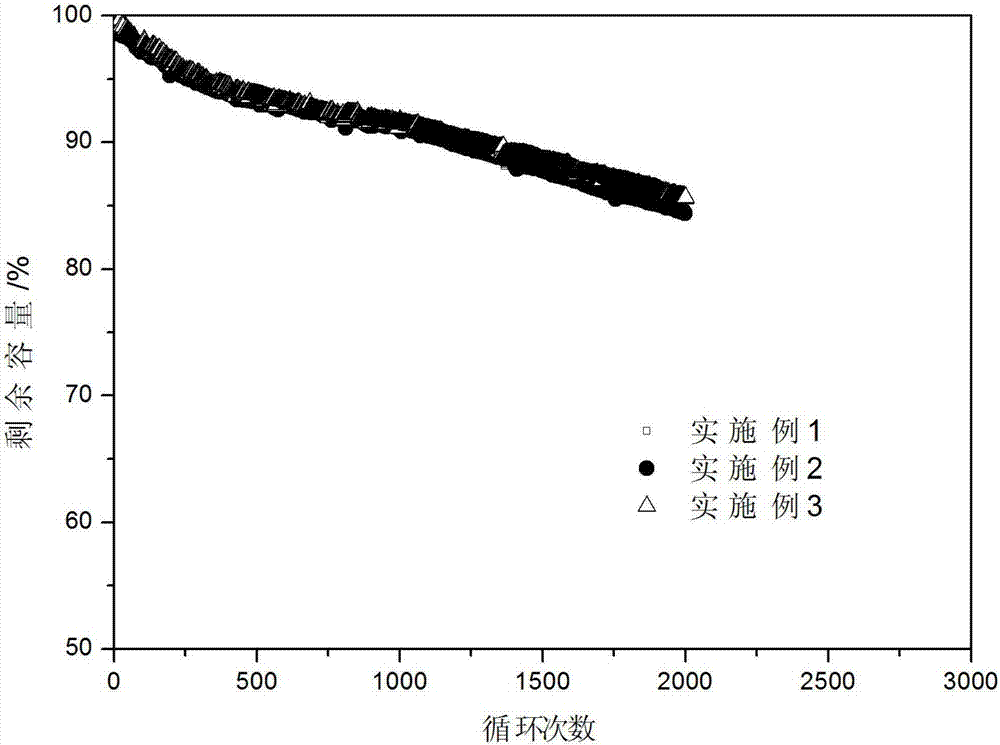

Embodiment 1

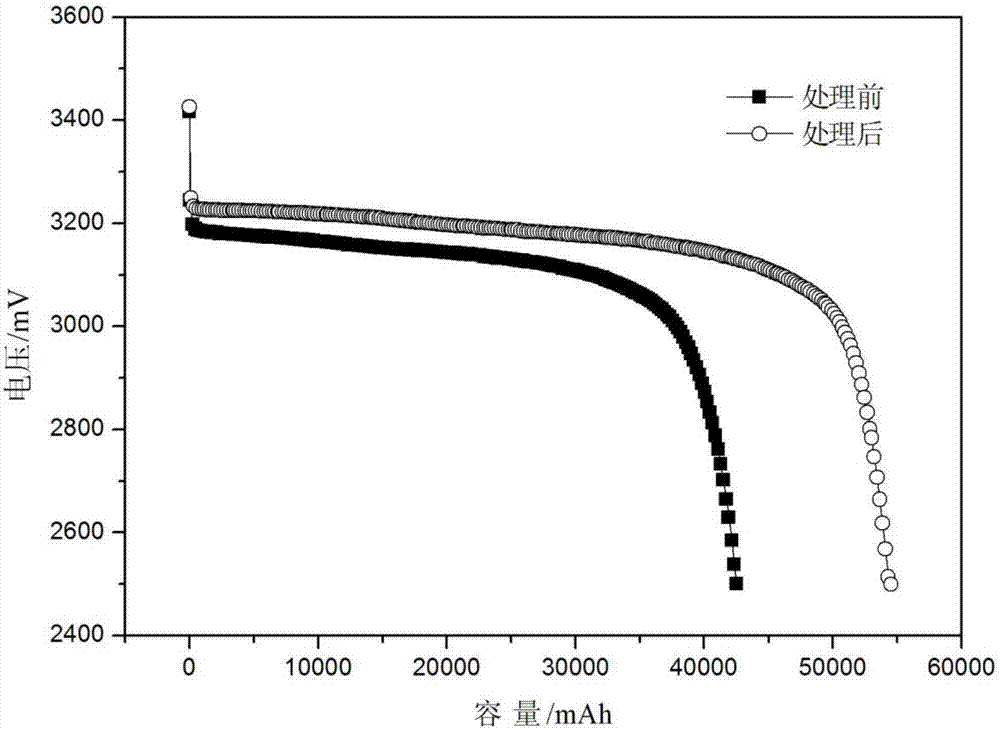

[0028] What embodiment 1 adopts is the IFP11200320-50Ah lithium iron phosphate battery that produces flatulence after the completion of production, and its design capacity center value is 53500mAh.

[0029] Embodiment 1 Eliminate flatulence of soft pack lithium ion battery with the method of the present invention

[0030] Use a fixture to apply 4Kg / cm to the inflated lithium iron phosphate battery IFP11200320-50Ah 2 The pressure is compressed; and then the battery is fully charged with a constant current and constant voltage method using a charge-discharge machine, specifically at a rate of 0.2I t (10A) current constant current charge to 3.6V, turn to constant voltage (3.6V) charge until the cut-off current ≤ 0.01I t (0.5A); Then, the clamp was depressurized and the battery was unloaded, and it was left at 25° C. for 30 days.

Embodiment 2

[0031] Embodiment 2 Eliminate flatulence of soft pack lithium ion battery with the method of the present invention

[0032] Use a fixture to apply 6Kg / cm to the inflated lithium iron phosphate battery IFP11200320-50Ah 2 The pressure is pressed tightly; the battery is fully charged with a constant current and constant voltage method using a charge-discharge machine, specifically at 0.2I t (10A) current constant current charge to 3.6V, turn to constant voltage (3.6V) charge until the cut-off current ≤ 0.01I t (0.5A); Then, the clamp was depressurized and the battery was unloaded, and it was left at 40° C. for 14 days.

Embodiment 3

[0033] Embodiment 3 eliminates flatulence of soft pack lithium ion battery with the method of the present invention

[0034] Use a fixture to apply 8Kg / cm to the inflated lithium iron phosphate battery IFP11200320-50Ah 2 The pressure is compressed; specifically, the first is to use 0.5I t (50A) constant current charging to 3.5V, and then 0.1I t After constant current charging to 3.6V, turn to constant voltage (3.6V) to charge until the cut-off current ≤ 0.01I t (0.5A); then, the clamp was depressurized and the battery was unloaded, and it was left at 50° C. for 5 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com