A kind of matcha pudding and preparation method thereof

A technology of tea pudding and matcha powder, which is applied in the field of dairy products, can solve the problems of not satisfying consumers' taste, flavor and enjoyment, and achieve the effect of good flavor and simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

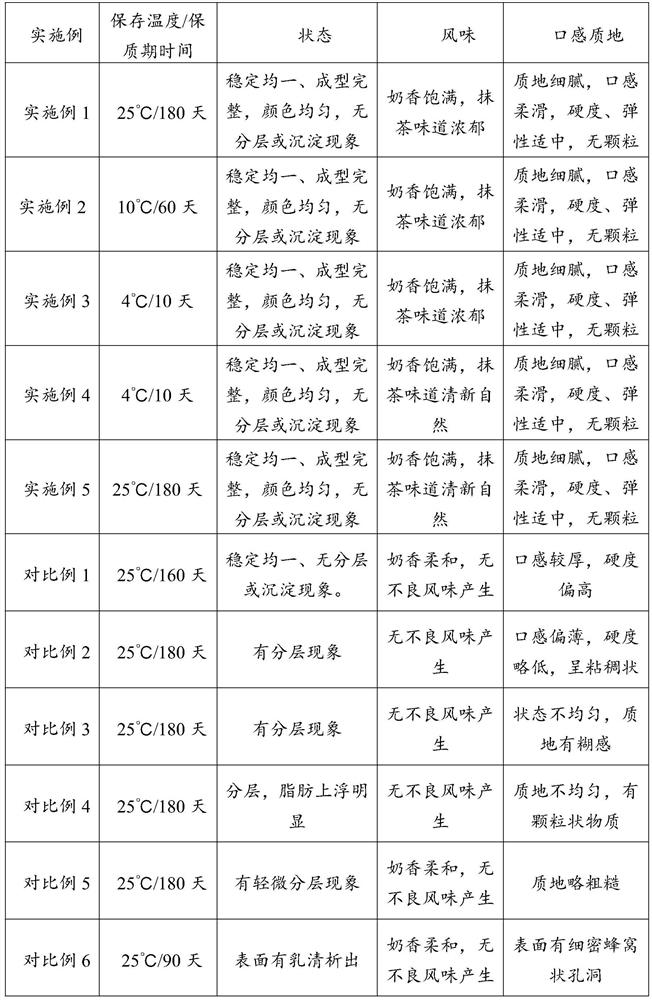

Examples

preparation example Construction

[0036] A preparation method of said matcha pudding, the method may further comprise the steps:

[0037] (1) Mix the sweetener, starch and water evenly to obtain a mixed solution A;

[0038] (2) Mix raw milk, mixed solution A, stabilizer, and matcha powder to obtain mixed solution B;

[0039] (3) Homogenize the mixed solution B;

[0040] (4) carrying out hot filling after the liquid obtained in step (3) is sterilized;

[0041] (5) cooling.

[0042] Specifically, in step (1), the specific operation of mixing is as follows: heating water or part of raw milk to 30-60°C, slowly adding starch and sweetener, stirring with heat preservation, and mixing evenly to obtain a mixed liquid A. The water is heated to 40-60°C, preferably 40-50°C. The mixing is a conventional operation in the art, and it is preferred to carry out the heat preservation operation during the mixing. Said mixing time can be conventional time in the field, preferably 15-30 min.

[0043] In step (2), the specif...

Embodiment 1

[0050] A formula of matcha pudding is shown in Table 1-1, wherein the composition of the stabilizer is shown in Table 1-2:

[0051] Table 1-1

[0052] raw material Amount added / % raw milk 80 cream 5 White sugar 12.5 stabilizer 0.3 starch 1.2 Matcha powder 1 total 100

[0053] Table 1-2

[0054] Mono-Glyceryl Distearate 40 carrageenan 30 xanthan gum 15 Locust Bean Gum 15 total 100

[0055] The preparation method of described matcha pudding comprises the following steps:

[0056] (1) Heat part of the raw milk to 30°C, slowly add starch and white sugar, keep warm and stir for 15 minutes, and mix well to obtain the mixed liquid A;

[0057] (2) Mix the remaining raw milk and cream with the mixed liquid A at 4°C, heat and stir for 15 minutes, mix well, heat to 70°C, add stabilizer and matcha powder, heat and stir for 15 minutes to obtain the mixed liquid B;

[0058] (3) Homogenize th...

Embodiment 2

[0062] A formula of matcha pudding is shown in Table 2-1, wherein the composition of the stabilizer is shown in Table 2-2:

[0063] table 2-1

[0064] raw material Amount added / % skim milk 70 cream 18 White sugar 8 fructose 2 stabilizer 0.4 starch 0.4 Matcha powder 1.2 total 100

[0065] Table 2-2

[0066] raw material Amount added / % Mono-Glyceryl Distearate 25 carrageenan 35 xanthan gum 25 Locust Bean Gum 15 total 100

[0067] The preparation method of described matcha pudding comprises the following steps:

[0068] (1) Heat part of the skimmed milk to 60°C, slowly add starch, white sugar and fructose, keep warm and stir for 20 minutes, and mix evenly to obtain the mixed solution A;

[0069] (2) Mix the remaining skim milk and cream with the mixed liquid A at 60°C, heat and stir for 20 minutes, mix well and heat to 80°C, add stabilizer and matcha powder, heat and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com