Precision duplex planetary reducer structure

A double-connected planetary and reducer technology, applied to mechanical equipment, transmission parts, gear transmissions, etc., to achieve the effects of compact structure, low noise, and high tooth surface contact rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

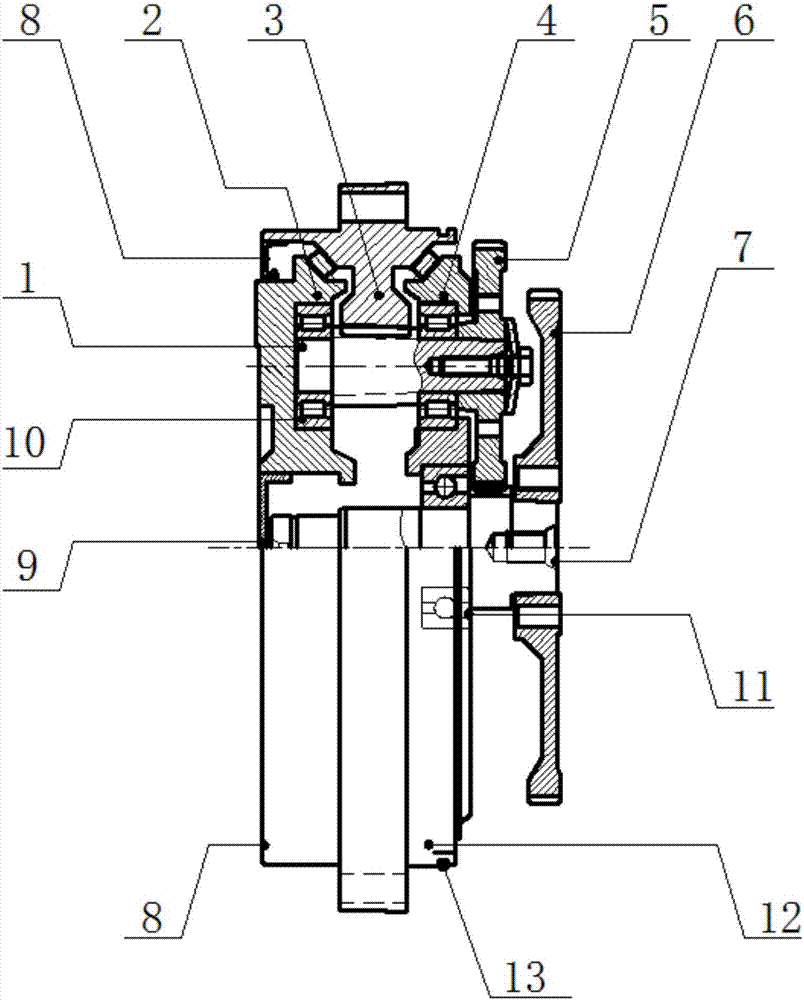

[0030] Such as figure 1 Shown: a precision double planetary reducer, including a separate planet carrier, two sets of meshing gear pairs and a helical drive wheel 6;

[0031] The separated planetary carrier includes a front-end planetary carrier 2 and a rear-end planetary carrier 4;

[0032] The two sets of meshing gear pairs include a first set of external meshing gear pairs and a second set of internal meshing gear pairs;

[0033] The first set of external meshing gear pairs includes several spur planetary gears 5 and spur sun gear pinion shafts 7, which are arranged outside the split planet carrier in mesh with each other;

[0034] The second set of internal meshing gear pairs includes several planetary pinion shafts 1 and fixed internal ring gears 3, and the two mesh with each other and are arranged inside the separated planetary carrier;

[0035] The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com