A round baler for corn harvesting green storage and yellow storage

A technology of baler and round baler, applied in the field of round balers for corn harvesting, green storage, yellow storage, can solve problems such as single function of harvester, and achieve the effects of improving labor efficiency, low power consumption, and easy feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with the accompanying drawings.

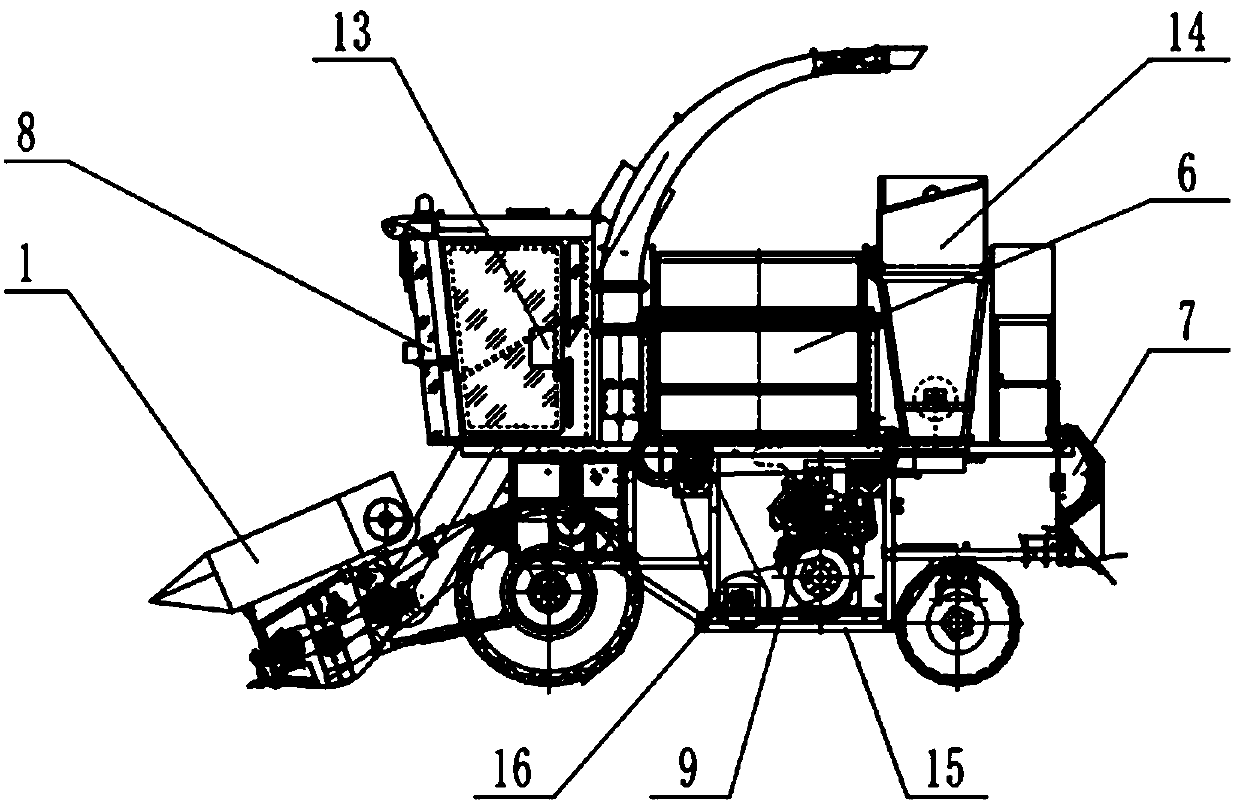

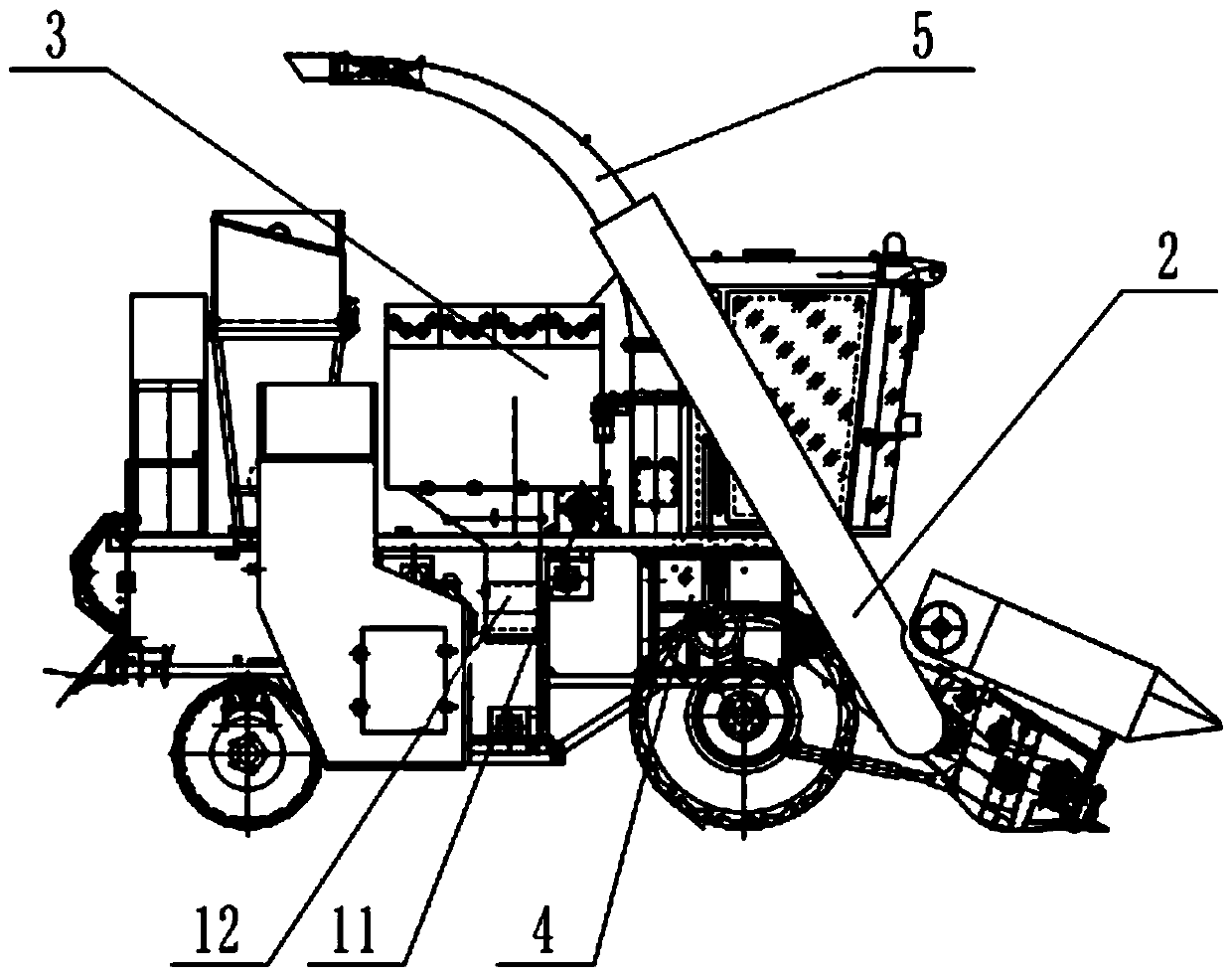

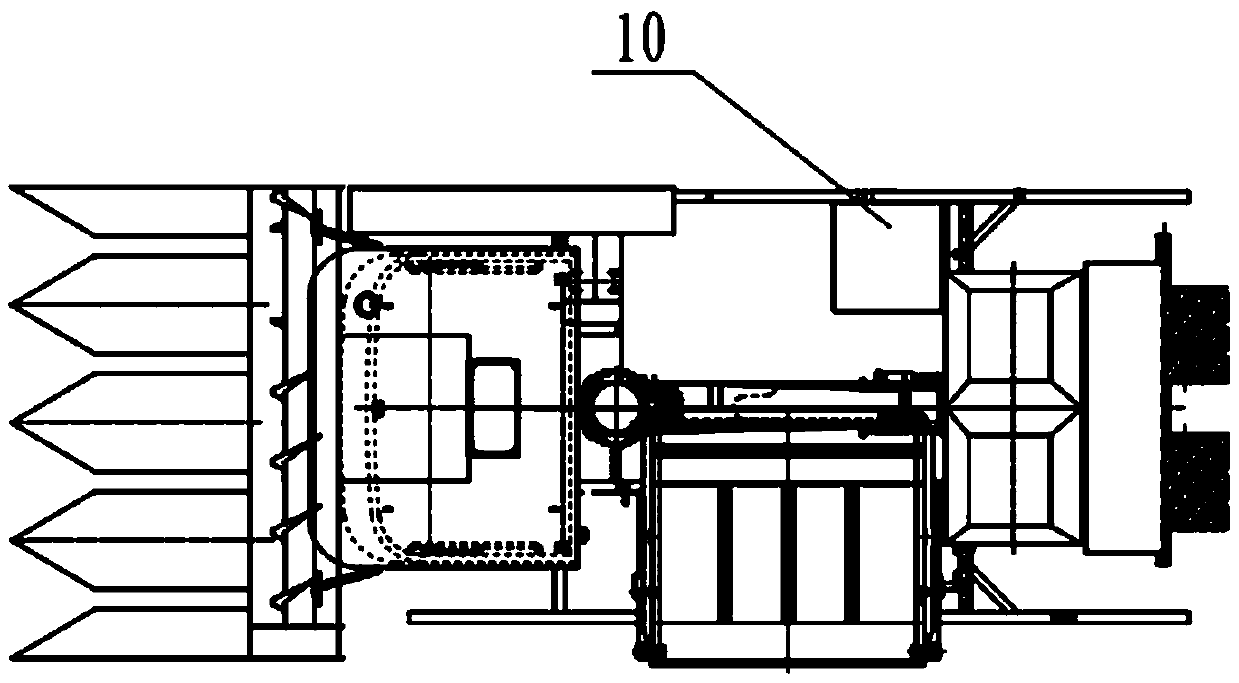

[0034] A round baler for corn harvesting green storage and yellow storage, including a car body, a double-layer cutting platform 1, a hoist 2, a peeling machine 3, a silk kneading machine 5, an ear box 6, a round baler 7, and a bag leaf crusher 11. The seed receiving box 12, the grass receiving box 14 and the throwing cylinder 5, wherein the double-layer cutting platform 1 includes an upper layer cutting platform and a lower layer cutting platform, the double-layer cutting platform 1 is located at the front end of the car body, and the upper layer cutting platform passes through 2 is connected to the peeling machine 3, the lower header is connected to the silk kneading machine 5 through a conveying trough, the ear box 6 is located at the left end of the peeling machine 3, the round baler 7 is located at the rear end of the car body, and the leaf breaker 11 is located at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com