Polyurethane shoe sole and preparation method thereof

A polyurethane and shoe sole technology, applied in the field of polyurethane materials, can solve the problems of no resistance, human body danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

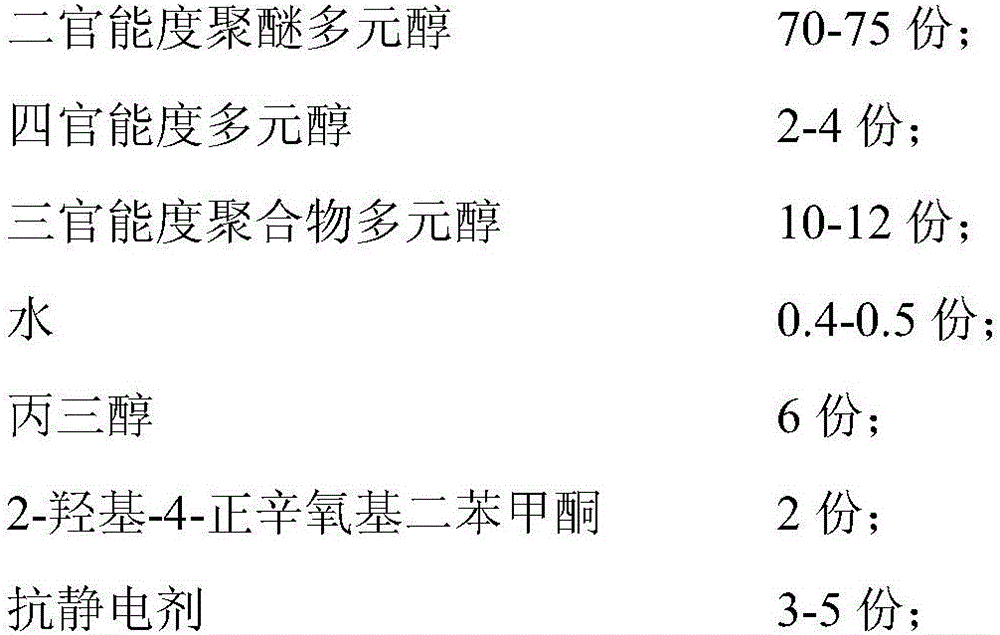

[0033] Polyurethane soles are casted by mixing components A and B. The composition and content of components A and B are shown in Table 1:

[0034] The polyurethane sole raw material table of table 1 embodiment 1

[0035]

[0036] MDI-polyester prepolymer is a prepolymer of 4-4'-diphenylmethane diisocyanate and polyethylene adipate, and the content of 4-4'-diphenylmethane diisocyanate is 93.8%.

[0037] Polyurethane sole preparation method is as follows:

[0038] (1) Preparation of component A

[0039] Add difunctional polyether polyol to tetrafunctional polyol, then add trifunctional polymer polyol; add glycerol, 2-hydroxy-4-n-octyloxybenzophenone and antistatic agent ;Stir for 15-20 minutes, stir evenly to form component A;

[0040] (2) Preparation of component B

[0041] Add 4-4'-diphenylmethane diisocyanate and polyethylene adipate to the reaction kettle in proportion to obtain component B;

[0042] (3) Polyurethane sole preparation

[0043] Add component A to the...

Embodiment 2

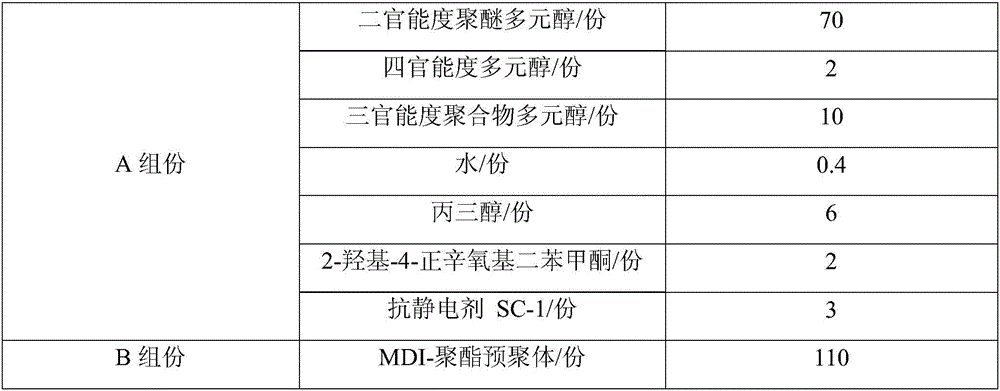

[0045] The polyurethane shoe sole is casted by mixing components A and B. The composition and content of the components A and B are shown in Table 2:

[0046] The polyurethane sole raw material table of table 2 embodiment 2

[0047]

[0048] MDI-polyester prepolymer is a prepolymer of 4-4'-diphenylmethane diisocyanate and polyethylene adipate, and the content of 4-4'-diphenylmethane diisocyanate is 93.8%.

[0049] Polyurethane sole preparation method is as follows:

[0050] (1) Preparation of component A

[0051] Add difunctional polyether polyol to tetrafunctional polyol, then add trifunctional polymer polyol; add glycerol, 2-hydroxy-4-n-octyloxybenzophenone and antistatic agent ;Stir for 15-20 minutes, stir evenly to form component A;

[0052] (2) Preparation of component B

[0053] Add 4-4'-diphenylmethane diisocyanate and polyethylene adipate to the reaction kettle in proportion to obtain component B;

[0054] (3) Polyurethane sole preparation

[0055] Add compone...

Embodiment 3

[0057] Polyurethane soles are casted by mixing components A and B. The composition and content of components A and B are shown in Table 3:

[0058] The polyurethane sole raw material table of table 3 embodiment 3

[0059]

[0060]

[0061] Polyurethane sole preparation method is as follows:

[0062] (1) Preparation of component A

[0063] Add difunctional polyether polyol to tetrafunctional polyol, then add trifunctional polymer polyol; add glycerol, 2-hydroxy-4-n-octyloxybenzophenone and antistatic agent ;Stir for 15-20 minutes, stir evenly to form component A;

[0064] (2) Preparation of component B

[0065] Add 4-4'-diphenylmethane diisocyanate and polyethylene adipate to the reactor to obtain component B;

[0066] (3) Polyurethane sole preparation

[0067] Add component A to the MDI-polyester prepolymer of component B, mix and cast, and ripen for 3 minutes to obtain a grounding, anti-static, two-way conduction polyurethane sole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com