Metal solid waste treatment system

A processing system and metal technology, applied in the field of metallurgy, can solve the problems of lack of processing cost, strong adaptability, low pollution, etc., and achieve the effects of no electromagnetic pollution, reduced maintenance cost, and low electrode consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

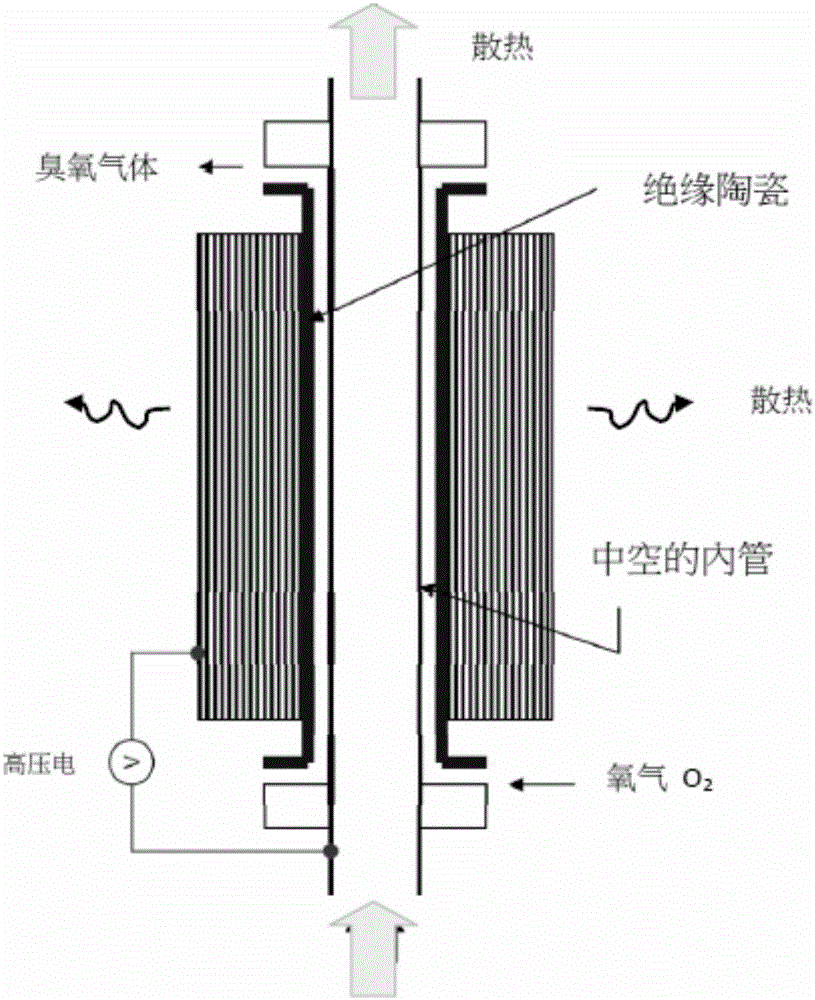

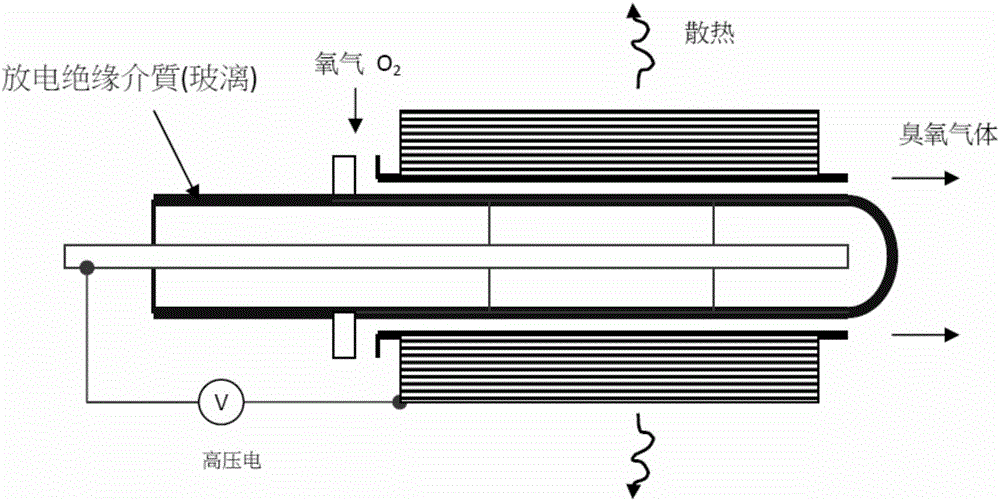

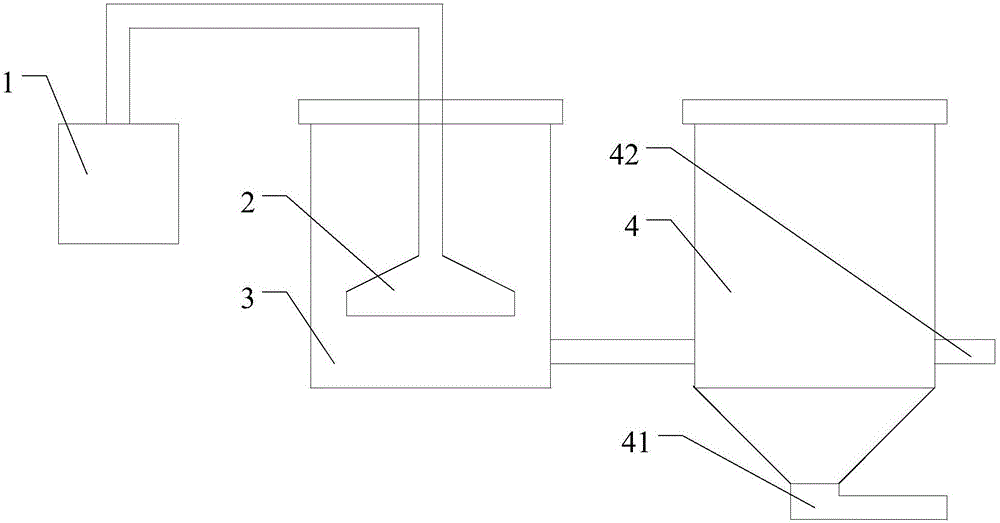

[0108] Put the liquid sample containing metal solid waste that needs to be treated into the stirring unit for stirring, and at the same time, pass the ozone generated by the ozone generating unit into the stirring unit through the aeration unit, so that the ozone can oxidize the metal solid waste in the liquid sample. The concentration of the ozone in every 1ml of liquid sample containing metal solid waste is ≥3ppm, preferably 3-10ppm. The stirring unit is a vortex stirring tank, and the vortex stirring tank is stirred by the rotation of the stirring blades. The humidity of the working environment of the ozone generating unit is ≤90%. The aeration unit is an aerator, and the bubbles generated by the aeration of the aerator are micro-nano bubbles, and the diameter of the micro-nano bubbles is 100nm-500μm.

[0109] Among them, the ozone generating unit generates ozone by placing water in the anode water tank and the cathode water tank respectively, the water in the anode water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com