AlCrSiCuN nano multilayer coating and preparation method thereof

A nano-composite coating and coating technology, applied in the field of tool coating and its preparation, AlCrSiCuN nano-multilayer tool coating and its preparation, to achieve the effects of high reliability, high precision and high feed speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

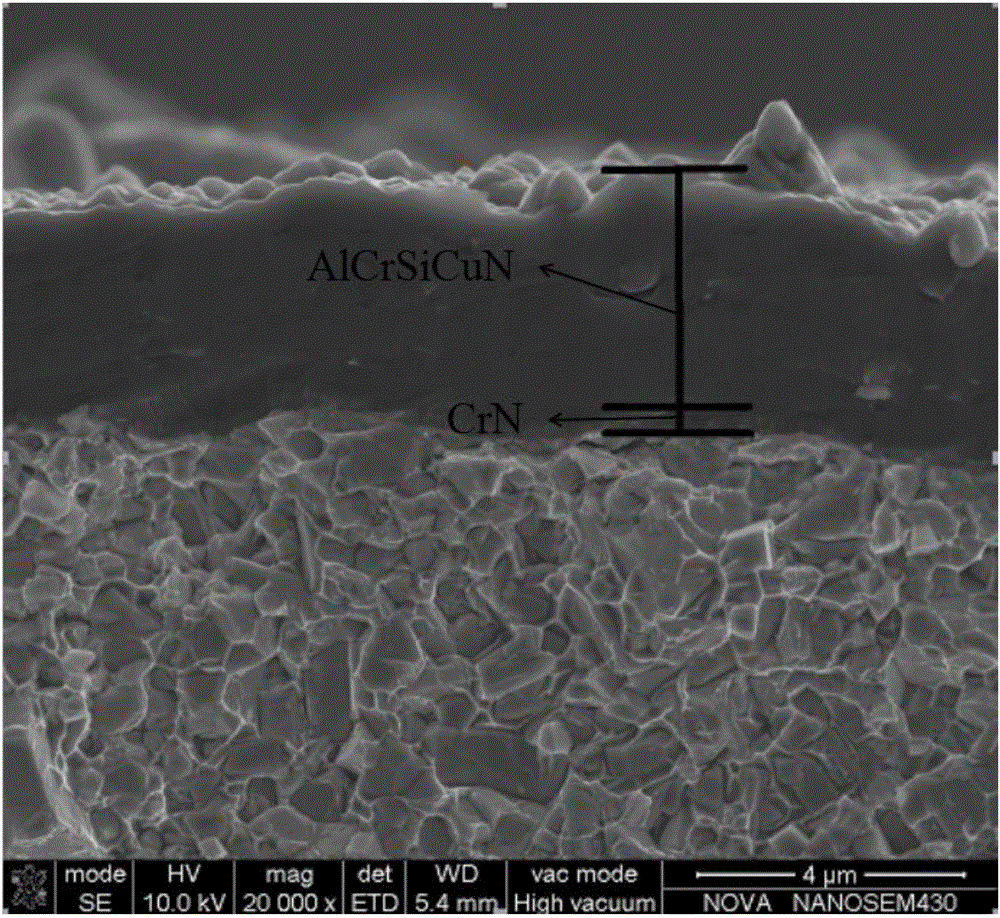

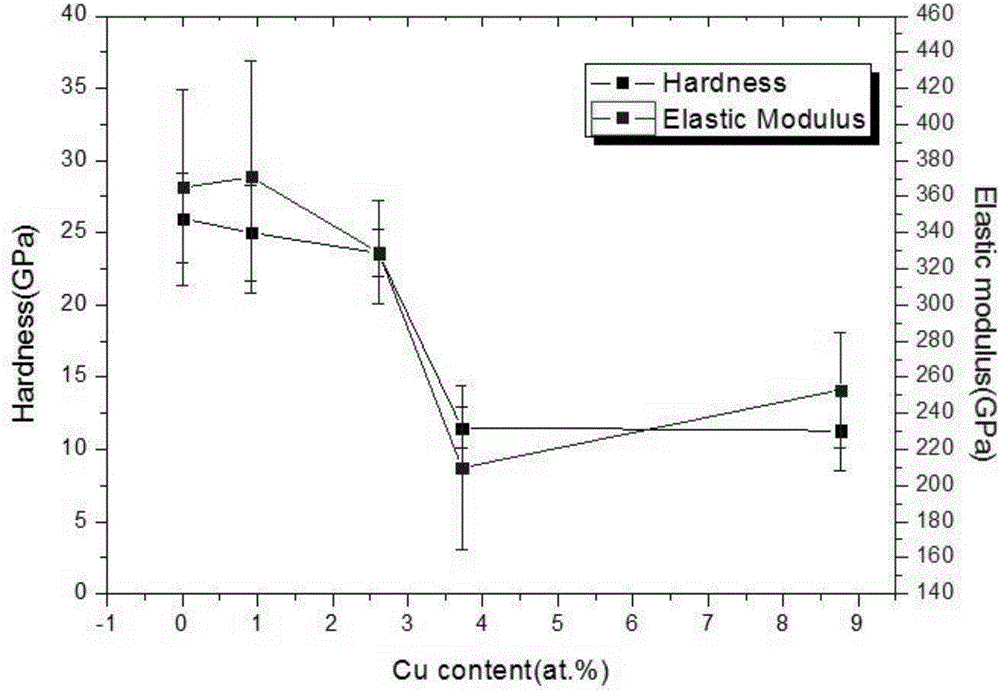

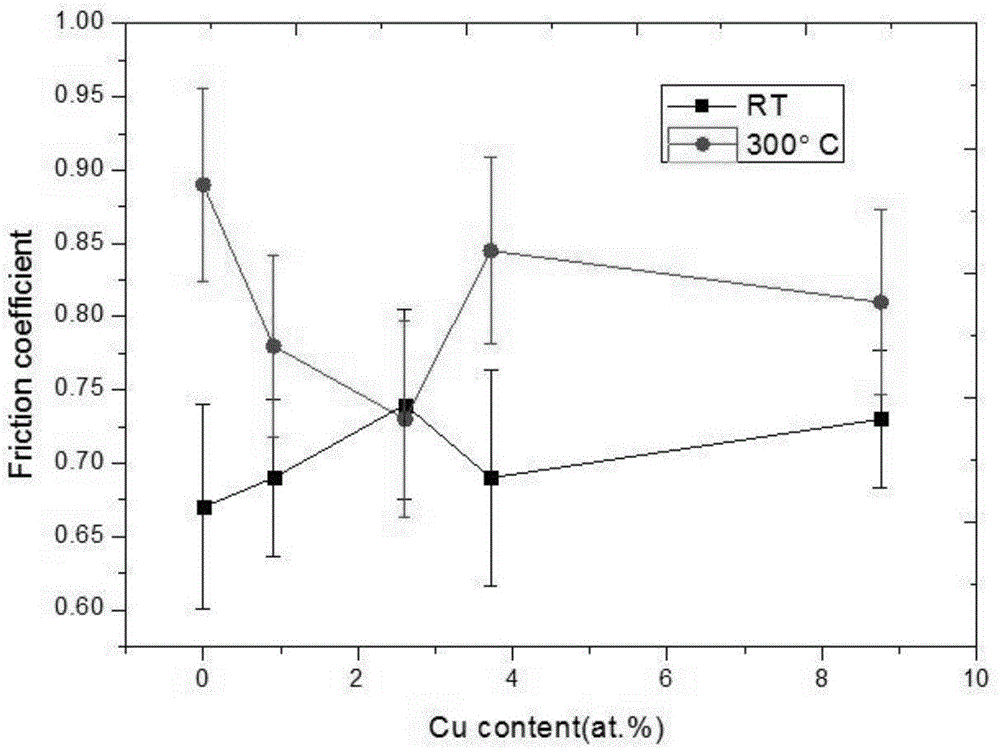

[0024] A kind of AlCrSiCuN nanocomposite cutting tool coating, is made up of the composition of following atomic percentage:

[0025] Al: 23.92 at. % Cr: 12.93 at. % Si: 8.02 at. % Cu: 0.91 at. % N: 54.21 at. %.

[0026] Put the samples into ultrasonic containers with absolute ethanol and acetone solution and clean them for 15 minutes respectively. After cleaning, dry the samples with general nitrogen and place them on the substrate holder in the cavity. Adjust the rotating speed of the workpiece support to 2.5rpm. Evacuate to a background vacuum of 5×10-3Pa, turn on the heater at the same time, heat the furnace chamber to 350°C; pass in 200sccm argon, adjust the air pressure to 1.2Pa, and apply a negative bias voltage of 1000V to the substrate for glow discharge cleaning , the cleaning time is 10min, which increases the cleanliness of the substrate surface and improves the bonding energy between the coating and the substrate; a negative bias voltage of 800V is applied to the ...

Embodiment 2

[0028] A kind of AlCrSiCuN nanocomposite cutting tool coating, is made up of the composition of following atomic percentage:

[0029] Al: 24.20 at. % Cr: 12.51 at. % Si: 8.00 at. % Cu: 2.61 at. % N: 52.68 at. %.

[0030] Put the samples into ultrasonic containers with absolute ethanol and acetone solution and clean them for 15 minutes respectively. After cleaning, dry the samples with general nitrogen and place them on the substrate holder in the cavity. Adjust the rotating speed of the workpiece support to 2.5rpm. Evacuate to a background vacuum of 5×10-3Pa, turn on the heater at the same time, heat the furnace chamber to 350°C; pass in 200sccm argon, adjust the air pressure to 1.2Pa, and apply a negative bias voltage of 1000V to the substrate for glow discharge cleaning , the cleaning time is 10min, which increases the cleanliness of the substrate surface and improves the bonding energy between the coating and the substrate; a negative bias voltage of 800V is applied to the ...

Embodiment 3

[0032] A kind of AlCrSiCuN nanocomposite cutting tool coating, is made up of the composition of following atomic percentage:

[0033]Al: 22.88 at. % Cr: 12.48 at. % Si: 7.75 at. % Cu: 3.72 at. % N: 53.17 at. %.

[0034] Put the samples into ultrasonic containers with absolute ethanol and acetone solution and clean them for 15 minutes respectively. After cleaning, dry the samples with general nitrogen and place them on the substrate holder in the cavity. Adjust the rotating speed of the workpiece support to 2.5rpm. Evacuate to a background vacuum of 5×10-3Pa, turn on the heater at the same time, heat the furnace chamber to 350°C; pass in 200sccm argon, adjust the air pressure to 1.2Pa, and apply a negative bias voltage of 1000V to the substrate for glow discharge cleaning , the cleaning time is 10min, which increases the cleanliness of the substrate surface and improves the bonding energy between the coating and the substrate; a negative bias voltage of 800V is applied to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com