Preparation method of high polymer based metal nano particle composite SERS substrate material

A nanoparticle and substrate material technology, applied in the field of nanomaterials, can solve the problems of complicated SERS substrate preparation and high cost, and achieve the effect of promoting long-term storage stability, low cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

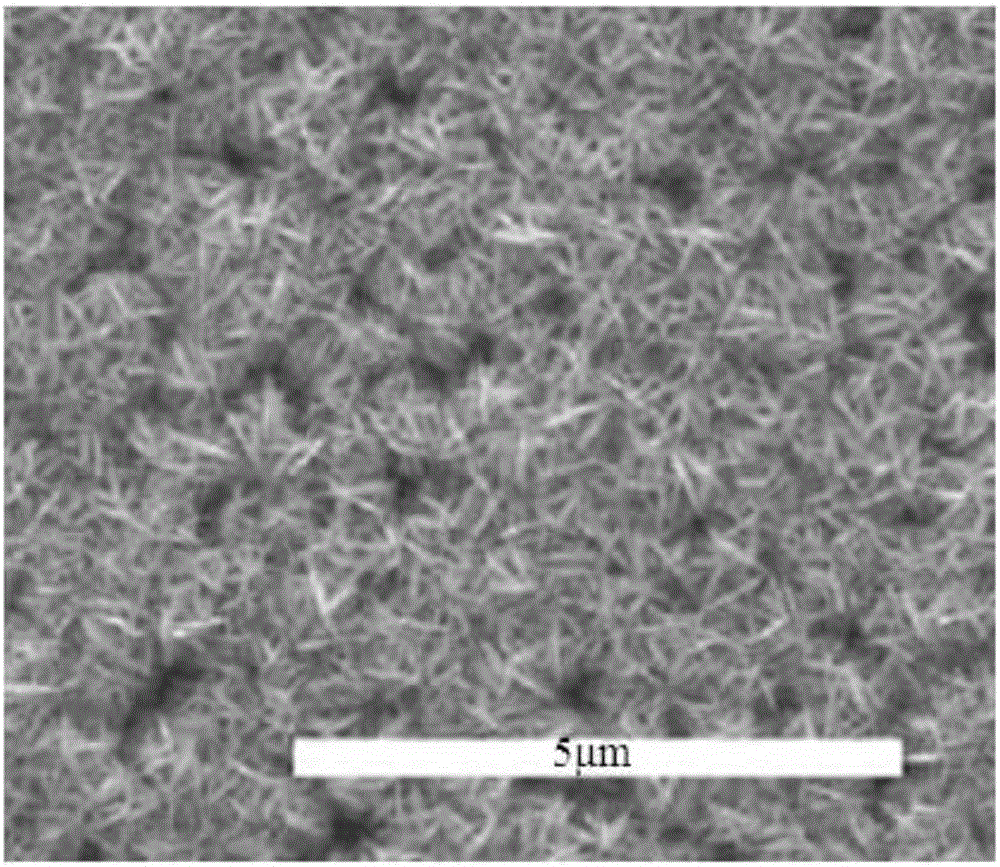

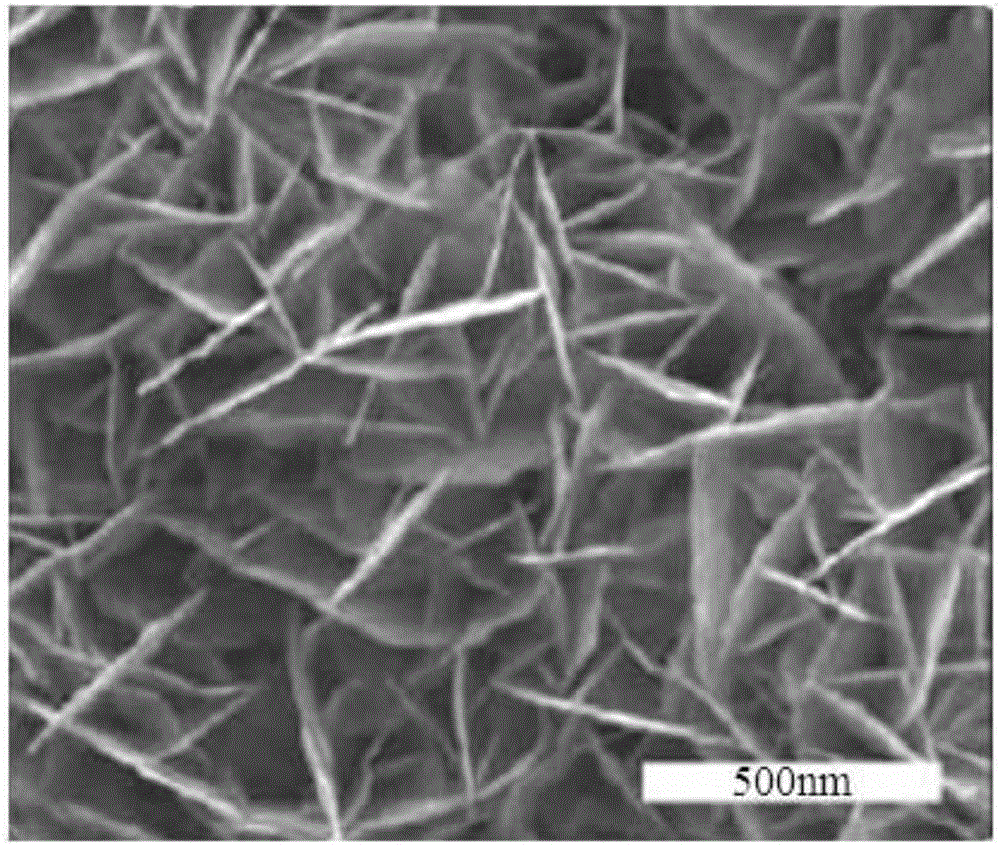

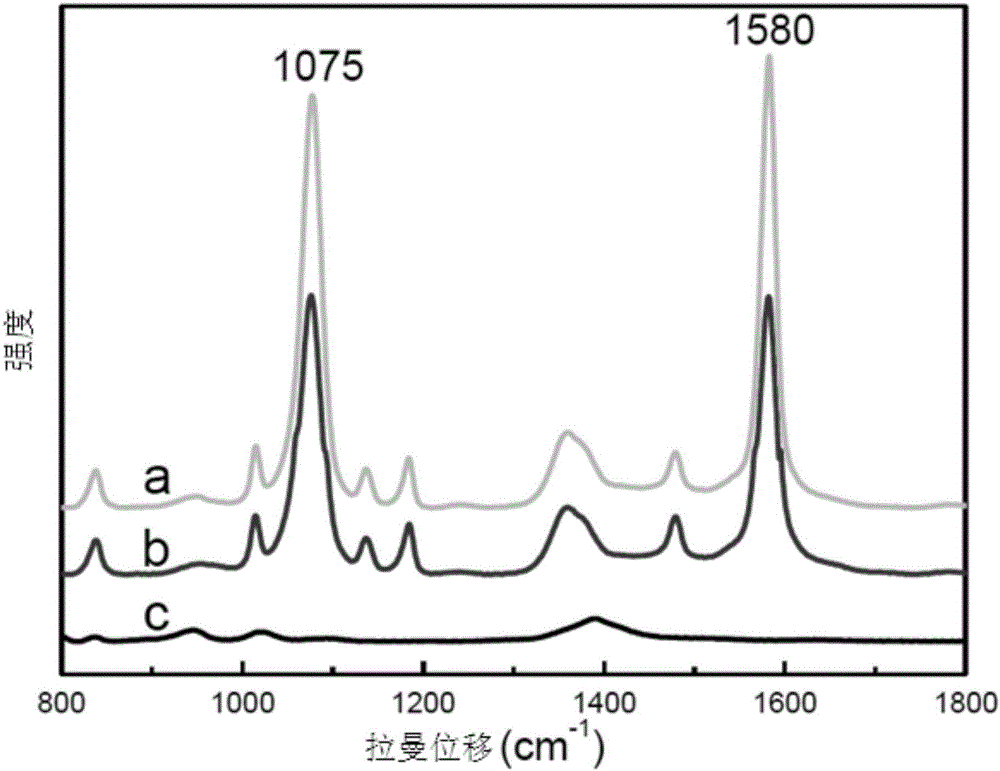

[0020] Embodiment 1: A method for preparing a polymer-based metal nanoparticle composite SERS substrate material according to this embodiment is carried out in the following steps:

[0021] 1. Add polyaniline powder, hexamethylimine and N,N-dimethylpyrrolidone into the container, and mix at a stirring speed of 50r / min to 100r / min until a uniform phase is formed to obtain a mixed solution;

[0022] 2. Coat the mixed solution obtained in step 1 on a glass slide to form a thin film, dry at a temperature of 70-90°C for 1.5h-2.5h, and then remove the thin film to obtain a polymer-based thin film;

[0023] 3. Mix the polymer-based film obtained in step 2 with the metal salt solution, and then irradiate it under gamma rays. The irradiation dose rate is 1kGy / h~20kGy / h, and the irradiation time is 1h~10h. drying under the condition of 70-90°C for 1.5h-2.5h to obtain the polymer-based metal nanoparticle composite SERS base material.

[0024] The mixing of the polymer-based film and the...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of polyaniline powder and hexamethylimine in step 1 is 2:0.5-1. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of polyaniline powder and hexamethylimine described in step 1 is 2:0.8. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com