Variable-frequency damping support device for space camera

A space camera and support device technology, applied in the field of aerospace optical remote sensors, can solve problems such as system complexity, uneconomical use, image distortion, etc., and achieve the effect of small size, strong adaptability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

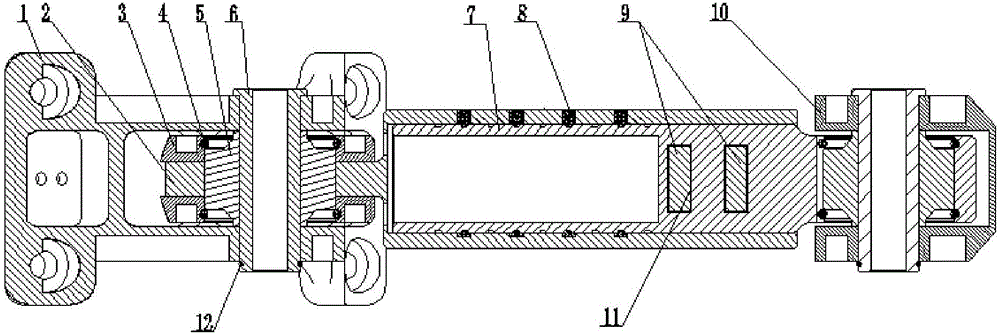

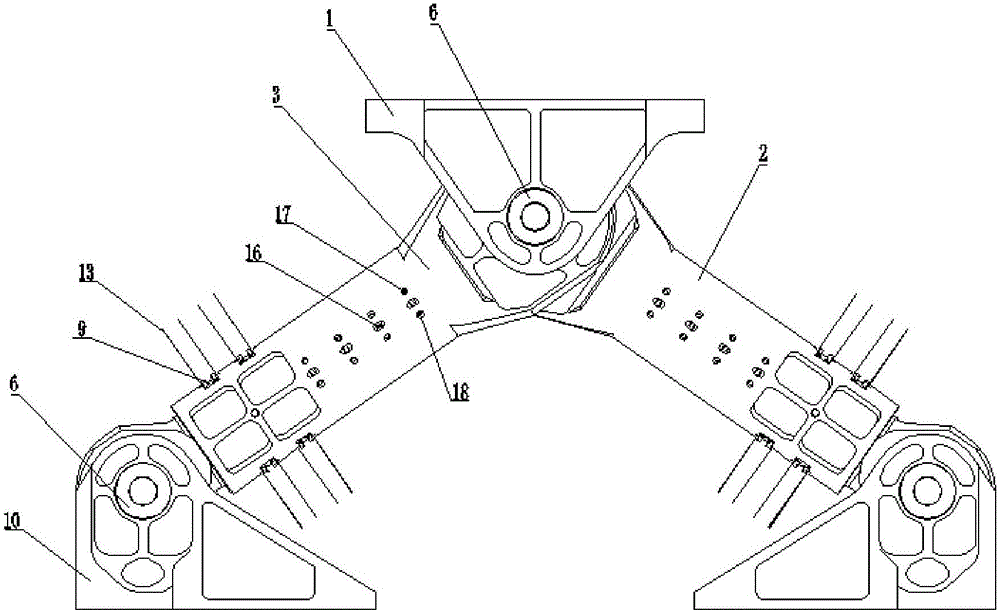

[0026] A variable frequency damping support device for a space camera such as Figure 1 ~ Figure 2 As shown, it includes upper hinge plate 1, outer connecting rod, steel wire retaining ring for hole 4, joint bearing 5, pin shaft 6, inner connecting rod 7, damping rubber layer 8, partition plate 9, lower hinge plate 10, rigidity rubber layer 11, steel wire retaining ring 12 for shaft. Among them, the outer connecting rod, the joint bearing 5, the inner connecting rod 7, the damping rubber layer 8, the partition plate 9, and the rigidity rubber layer 11 are its core components.

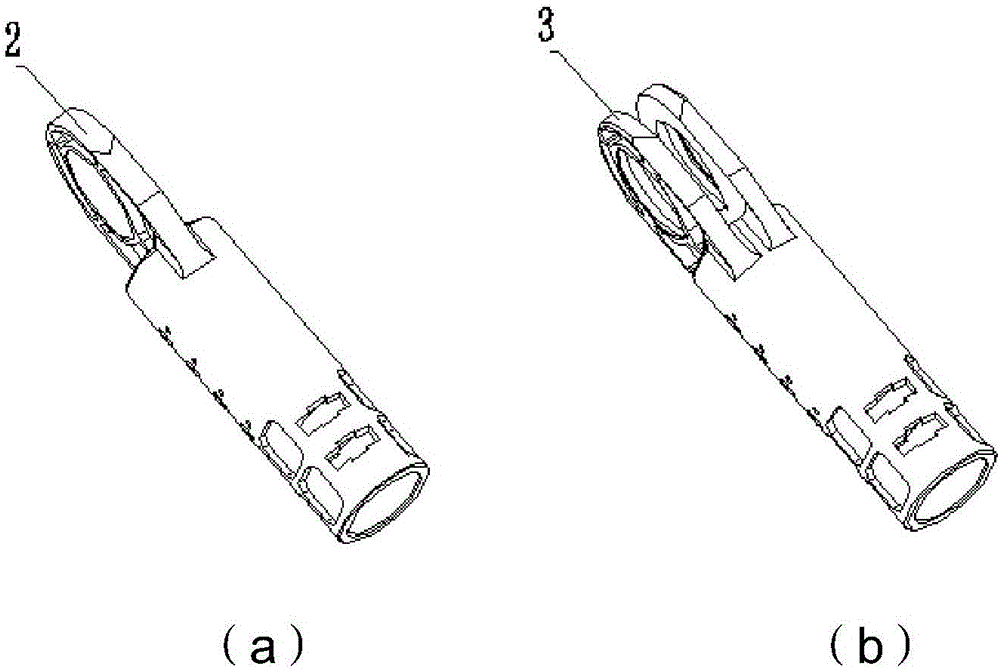

[0027] like image 3 (a), image 3 As shown in (b), the outer connecting rod includes an outer connecting rod one 2 and an outer connecting rod two 3; the outer connecting rod one 2 is cylindrical, and the end of the cylinder has an installation ring that cooperates with the joint bearing 5 and the pin shaft 6; The connecting rod 2 3 is cylindrical, and the end of the cylinder has two parallel mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com