Nano flow capacitive liquid level sensor and manufacturing method thereof

A liquid level sensor, capacitive technology, applied in the field of liquid level sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

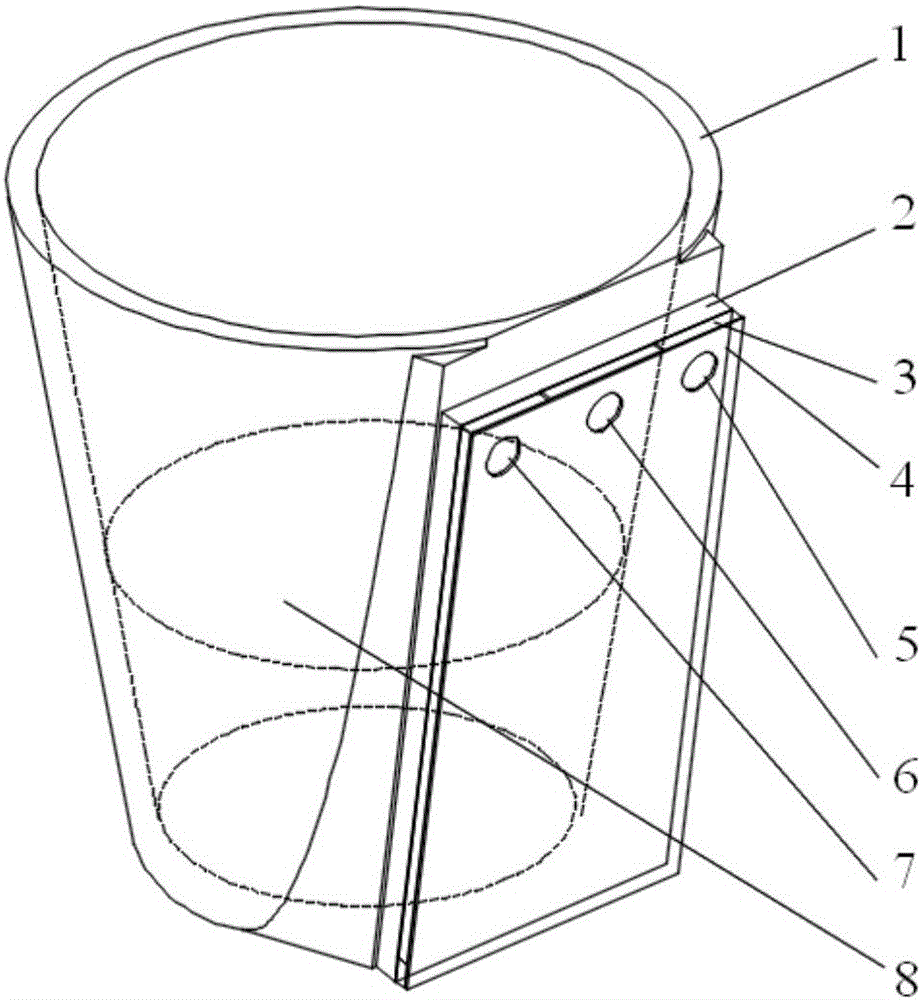

[0034] Such as figure 1 Shown: a continuous nanoliter capacitive liquid level sensor based on MEMS technology, suitable for the bioreactor structure in the field of microfluidics, the liquid level sensor is installed on the outer surface of the bioreactor 1, and the bioreactor 1 is opened There are a container outlet 12 and a container inlet 9, the liquid in the bioreactor 1 enters the liquid level sensor through the container outlet 12, and then returns to the bioreactor 1 from the container inlet 9.

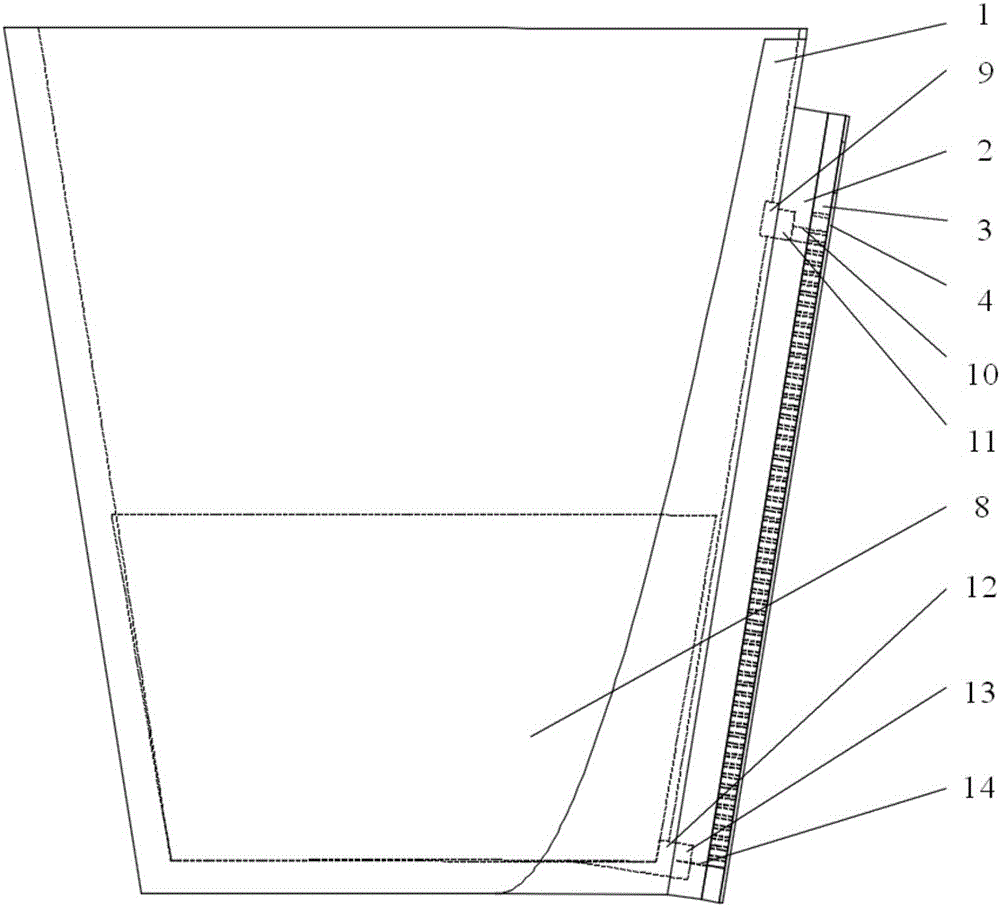

[0035] Such as figure 2 As shown, the capacitive liquid level sensor includes: PDMS layer 2 , Si structure layer 3 and glass layer 4 . Among them, the function of PDMS layer 2 is to encapsulate the sensor on the outer surface of the bioreactor. Of course, other materials can be used in addition to PDMS, as long as the sensor can be encapsulated on the outer surface of the bioreactor. In order to communicate with the interior of the bioreactor, the PDMS layer is provided with...

Embodiment 2

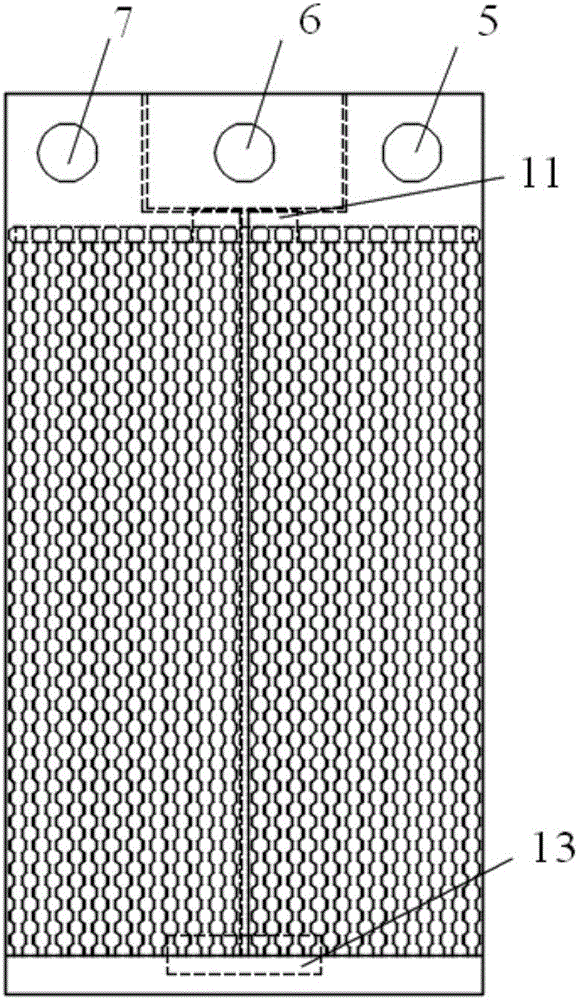

[0043] Such as Figure 8 As shown, the difference between this embodiment and one of the specific embodiments is that: the horizontal gaps 19 are equidistantly arranged between the serpentine inner surface gaps, and the oxidation insulation treatment is done; the other is the same as the one of the specific embodiments. This embodiment can accurately monitor individual sensitive liquid level points on the basis of continuous liquid level measurement. When the liquid level reaches the transverse gap, the capacitance change of the system is obviously higher than usual, which is very beneficial for occasions that are sensitive to liquid level and volume transmission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com