A Cold Cathode Radiation Source Based on Helical Ribbon Electron Injection

A strip electron, cold cathode technology, applied in the fields of submillimeter wave and terahertz electric vacuum devices, microwaves, and millimeter waves, can solve the problems of current on the surface of the medium, reduce the voltage resistance of the device, and spark, and achieve increased Interaction area, stabilization and miniaturization, the effect of increasing the emission area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

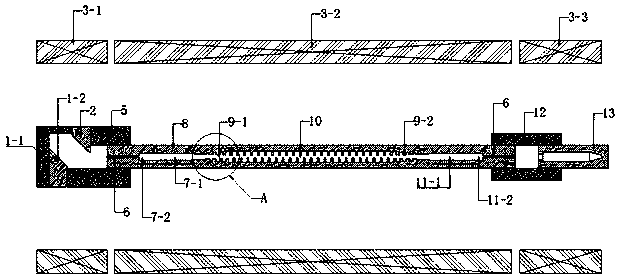

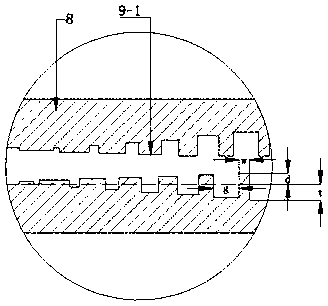

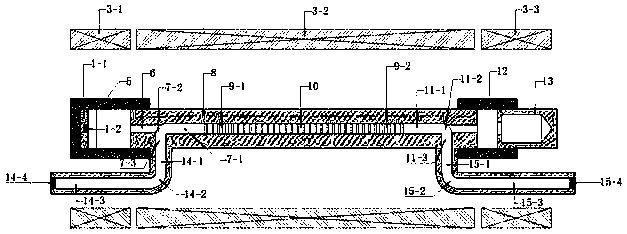

[0038] Such as Figure 1-5 As shown, this implementation case provides a kind of cold cathode radiation source based on spiral ribbon electron injection, which mainly includes spiral ribbon injection electron gun (by cathode block 1-1, cathode emission surface 1-2, anode block 2, electron gun packaging insulator 5), guiding magnetic field 3 (generated by electron gun magnetic field generator 3-1, high-frequency system magnetic field generator 3-2, collector pole magnetic field generator 3-3), periodic structure metal shell 8 and collector pole 13 and other components , the spiral ribbon electron injection cold cathode radiation source system is not filled with medium (it is a vacuum environment). The materials of the cathode emitting surface 1-2 of the electron g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com