An Injection-Wave Interaction Structure for Multi-Injection High-Order Mold Based on Cold Cathode

A technology of injection wave interaction and interaction, applied in the field of injection wave interaction structure, can solve the problems of device damage, reduce system efficiency, output power and efficiency reduction, etc., achieve high output power and efficiency, increase emission area, The effect of reducing the beam density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

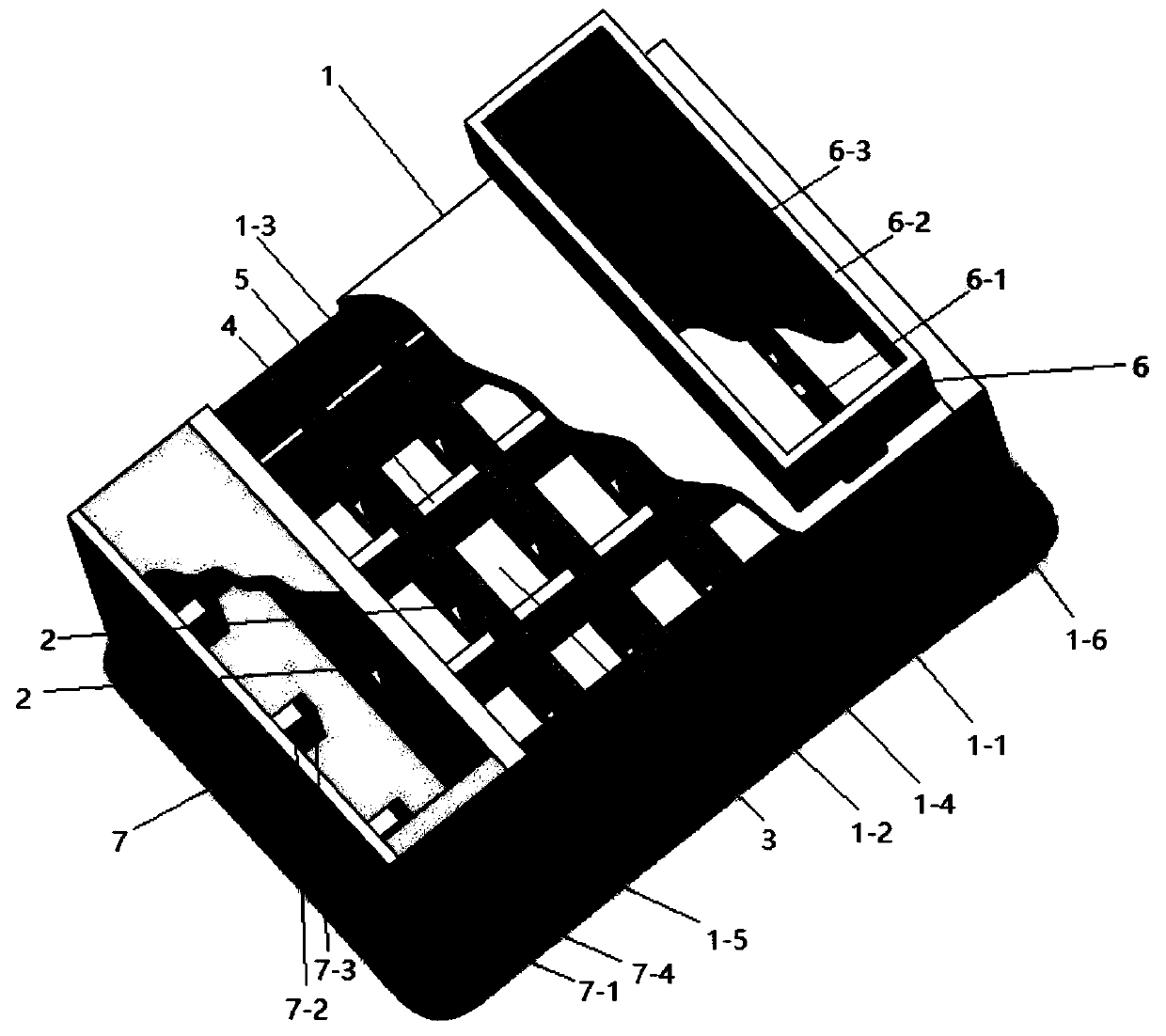

[0023] This embodiment provides a multi-injection high-order mold injection-wave interaction structure based on cold cathodes. This embodiment takes the cold-cathode-based multi-injection high-order mold injection-wave interaction structure for the 0.1 THz frequency band as an example:

[0024] Such as figure 1 As shown, it is a schematic diagram of the multi-injection high-order mold injection wave interaction structure based on cold cathodes in this embodiment, including: a high-frequency interaction structure, a cold-cathode electron gun sealed with one end of the high-frequency interaction structure, and a high-frequency interaction structure. The collection stage which is sealed and connected at the other end of the interaction structure and the output system arranged on the top of the high frequency interaction structure;

[0025]Wherein, cold cathode electron gun 7 comprises: electron gun housing, electron gun base, 3 cathode struts and 3 cathode emitters, one end of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com