Holographic laser film coated non-contact IC (Integrated Circuit) card

A non-contact, film bonding technology, applied in the direction of cards, synthetic resin layered products, record carriers used by machines, etc., can solve the problems of increased manpower and material resources required for production, increased scrap rate, and high production costs, and achieve enhanced Surface effect performance, low frequency loss, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

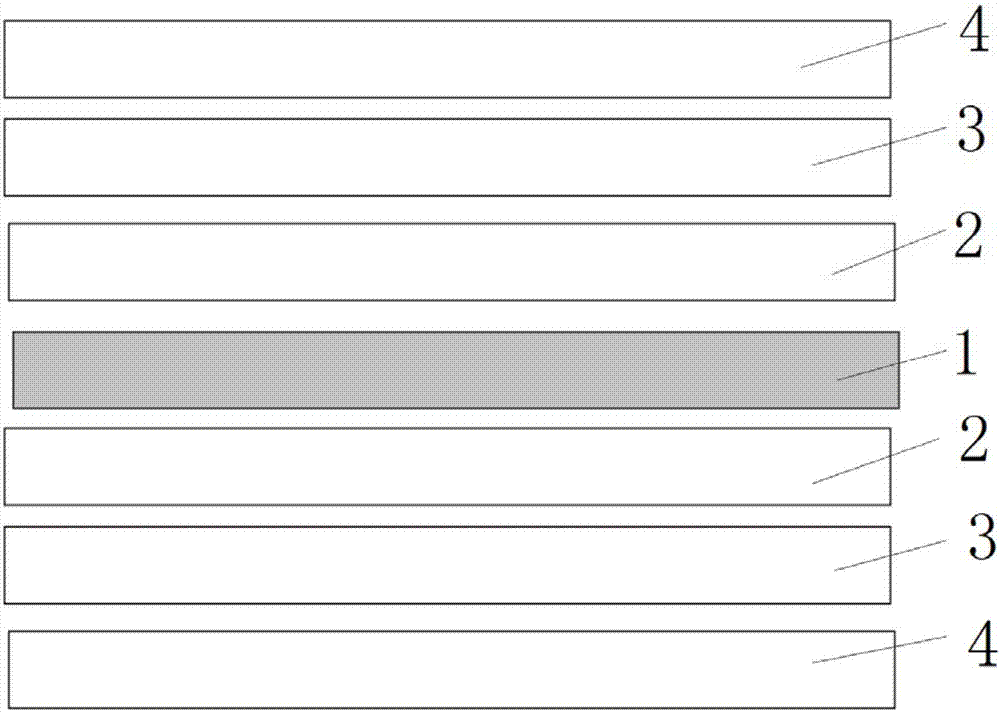

[0022] refer to figure 1 , figure 2 As shown, a non-contact IC card bonded with a holographic laser film includes an IC chip 1 and a card structure, the IC chip 1 is arranged in the card structure, and the card structure includes an upper side card structure, a lower side Card structure, the upper side card structure includes a holographic PET / PVC laser plastic layer group 2, a printing layer 3, a PET / PVC film layer 4 sequentially arranged on the IC chip 1 from the inside to the outside, and the holographic PET The / PVC laser plastic layer group 2 is used to realize functions such as holographic pattern and laser pattern, the printing layer 3 is used for pattern printing, and the PET / PVC film layer 4 is used to protect the inner layer.

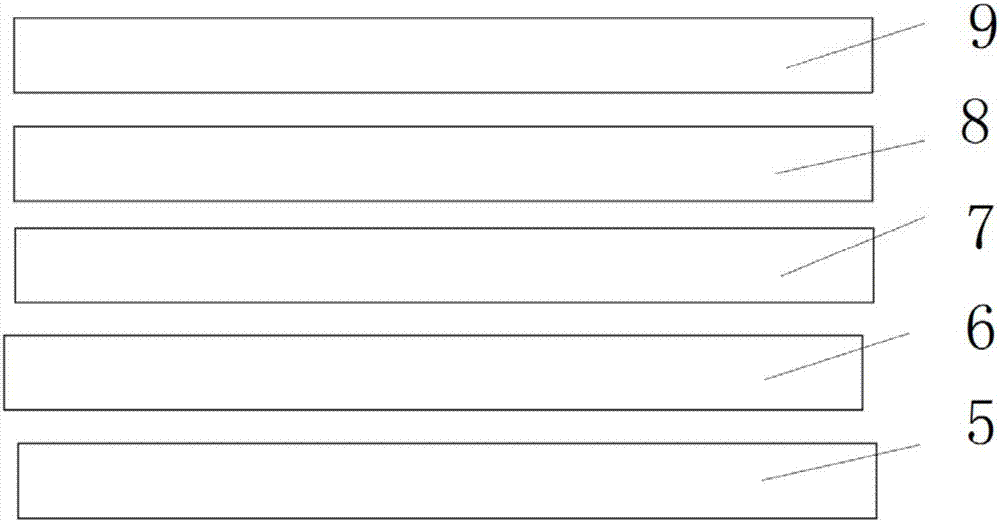

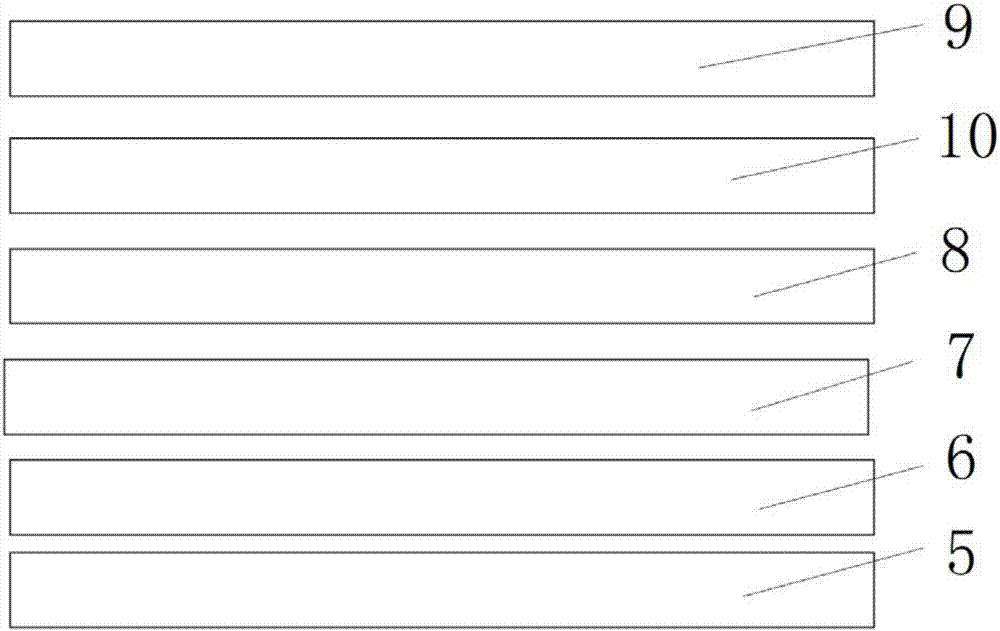

[0023] The holographic PET / PVC laser plastic layer group 2 includes a PET / PVC plastic layer 5, a glue layer 6, a combined layer 7, a metallized layer / nano new material layer 8, and a PET / PVC base film layer arranged in sequence from the insi...

Embodiment 2

[0029] refer to Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the lower card structure includes a PET / PVC plastic layer 5, a printing layer 3, a PET / PVC plastic layer 5, a printing layer 3, and a PET / PVC layer arranged on the IC chip 1 from the inside to the outside. Thin-film layer 4, that is, the lower side of the IC card does not have holographic or laser effects.

[0030] Under the same conditions, after testing, when the metal-plated layer / nano new material layer is an aluminum-plated layer, the layer thickness of the existing holographic process Compared with the effect that the maximum distance that can be read by single-sided use is 35-40mm, and the maximum distance that can be read by double-sided use is 25-30mm, using the IC card of the present invention, the single-sided one in Embodiment 2 has holographic and laser effects. The maximum reading distance is 40-45mm, the reading distance is increased by 5±2mm, and the frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com