Low frequency loss gan-based microwave power device and manufacturing method thereof

A technology of microwave power and manufacturing method, applied in the field of microelectronics, can solve problems such as improving and affecting the working performance of devices, and achieve the effects of reducing frequency loss, increasing gate-source spacing, and reducing gate-source parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

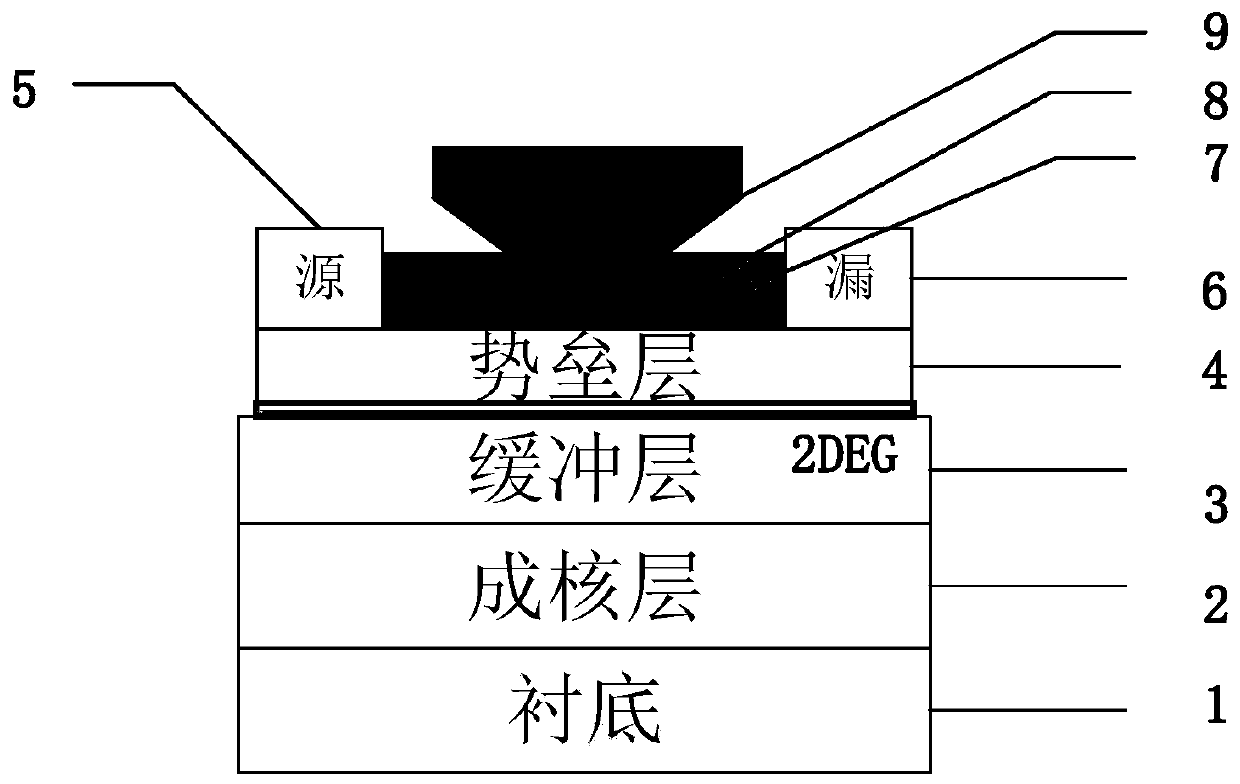

[0030] Embodiment 1: A low-frequency loss GaN-based microwave power device is manufactured on a SiC substrate with a SiN passivation layer thickness of 200 nm, a BN passivation layer growth thickness of 50 nm, and a passivation layer etching thickness of 60 nm.

[0031] The device is manufactured on the purchased epitaxial substrate sample which already contains substrate, nucleation layer, buffer layer and potential barrier layer.

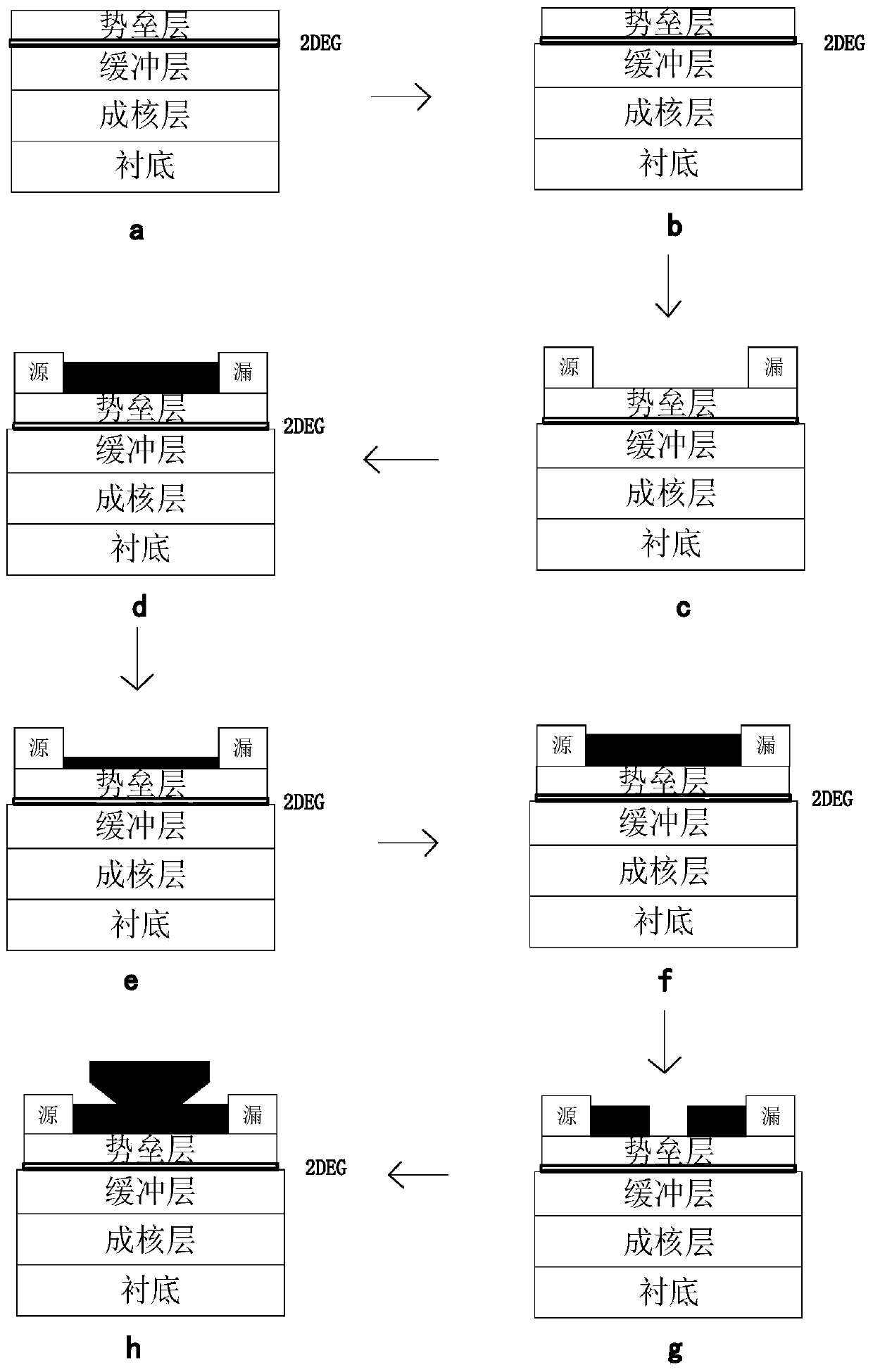

[0032] Step 1, cleaning the epitaxial substrate sample, such as figure 2 (a) shown.

[0033] First place the sample in acetone and sonicate for 2 minutes, then boil it for 10 minutes in a positive glue stripping solution heated in a water bath at 60°C, then place the sample in acetone and ethanol for 3 minutes each, and wash off the residual residue with deionized water. Acetone, ethanol; finally, clean the wafer with HF solution for 30 seconds, then clean it with deionized water and dry it with ultra-pure nitrogen.

[0034] Step 2, use ICP equ...

Embodiment 2

[0106] Embodiment 2, a low-frequency loss GaN-based microwave power device is fabricated on a sapphire substrate with a SiN passivation layer thickness of 100 nm, a BN passivation layer growth thickness of 20 nm, and a passivation layer etching thickness of 30 nm.

[0107] Step 1: Select an epitaxial substrate sample with a substrate, a nucleation layer, a buffer layer, and a barrier layer formed thereon, and clean the substrate.

[0108] The specific implementation of this step is the same as step 1 in the first embodiment.

[0109] Step 2, use ICP equipment to etch the mesa to the barrier layer to realize active area isolation;

[0110] (2.1) Photolithographically isolate regions on the barrier layer:

[0111] The concrete realization of this step is identical with the step 2a) among the embodiment one;

[0112] (2.2) Etching the electrical isolation region on the barrier layer:

[0113] The concrete realization of this step is identical with the step 2b) among the embodi...

Embodiment 3

[0150] Embodiment 3, a low-frequency-loss GaN-based microwave power device is manufactured on a sapphire substrate with a SiN passivation layer thickness of 150 nm, a BN passivation layer growth thickness of 30 nm, and a passivation layer etching thickness of 50 nm.

[0151] In step A, select an epitaxial substrate on which a substrate, a nucleation layer, a buffer layer, and a barrier layer have been formed, and clean the substrate.

[0152] The specific implementation of this step is the same as step 1 in the first embodiment.

[0153] Step B, using ICP equipment to etch the mesa to the barrier layer to realize active area isolation;

[0154] (B1) Photolithographically isolate regions on the barrier layer:

[0155] The concrete realization of this step is identical with the step 2a) among the embodiment one;

[0156] (B2) Etching the electrical isolation region on the barrier layer:

[0157] The concrete realization of this step is identical with the step 2b) among the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com