glasses lens

A spectacle lens and plastic lens technology, which is applied in glasses/safety glasses, glasses/goggles, instruments, etc., and can solve the problems of reduced transmittance and large reduction in visual transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

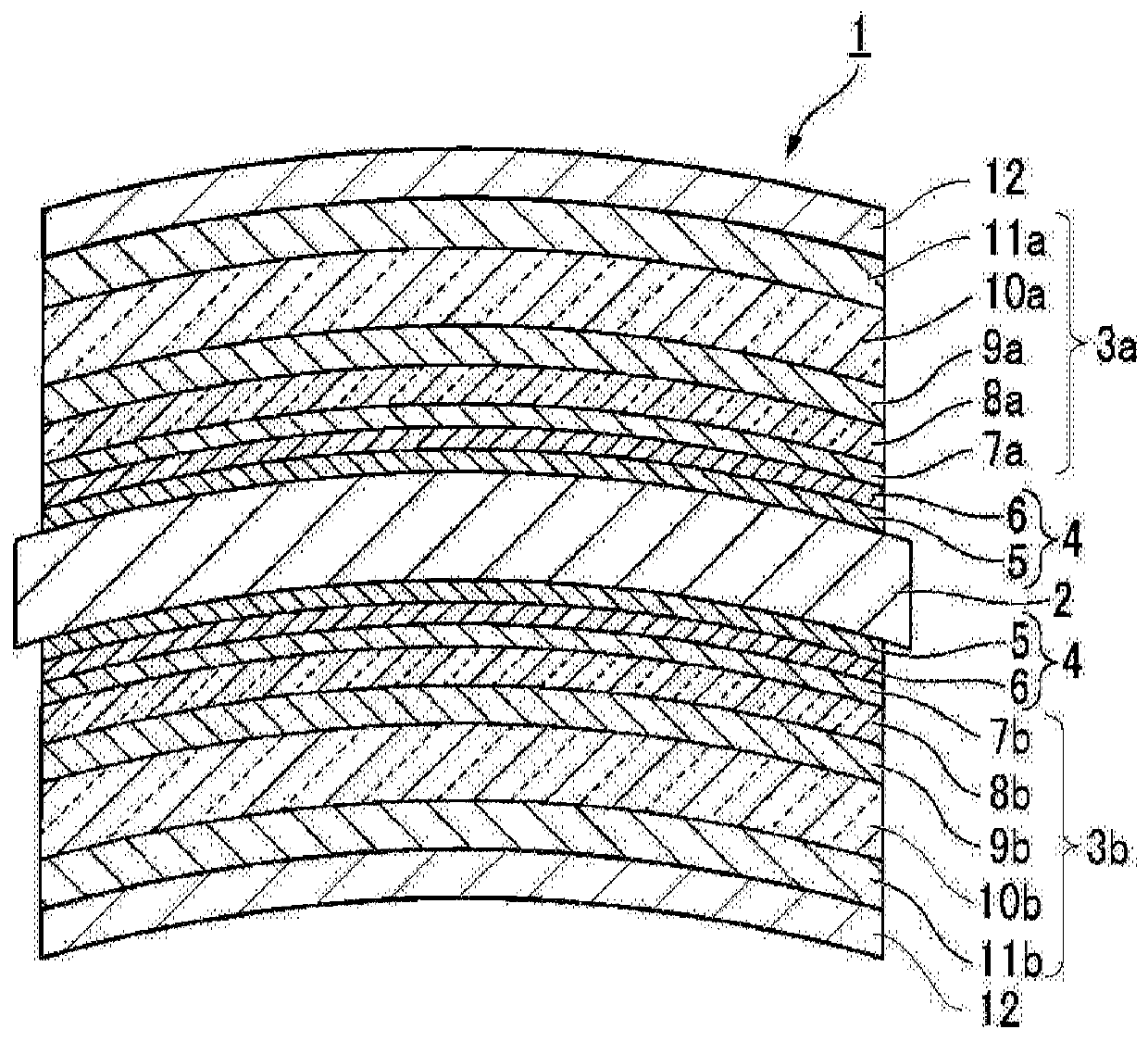

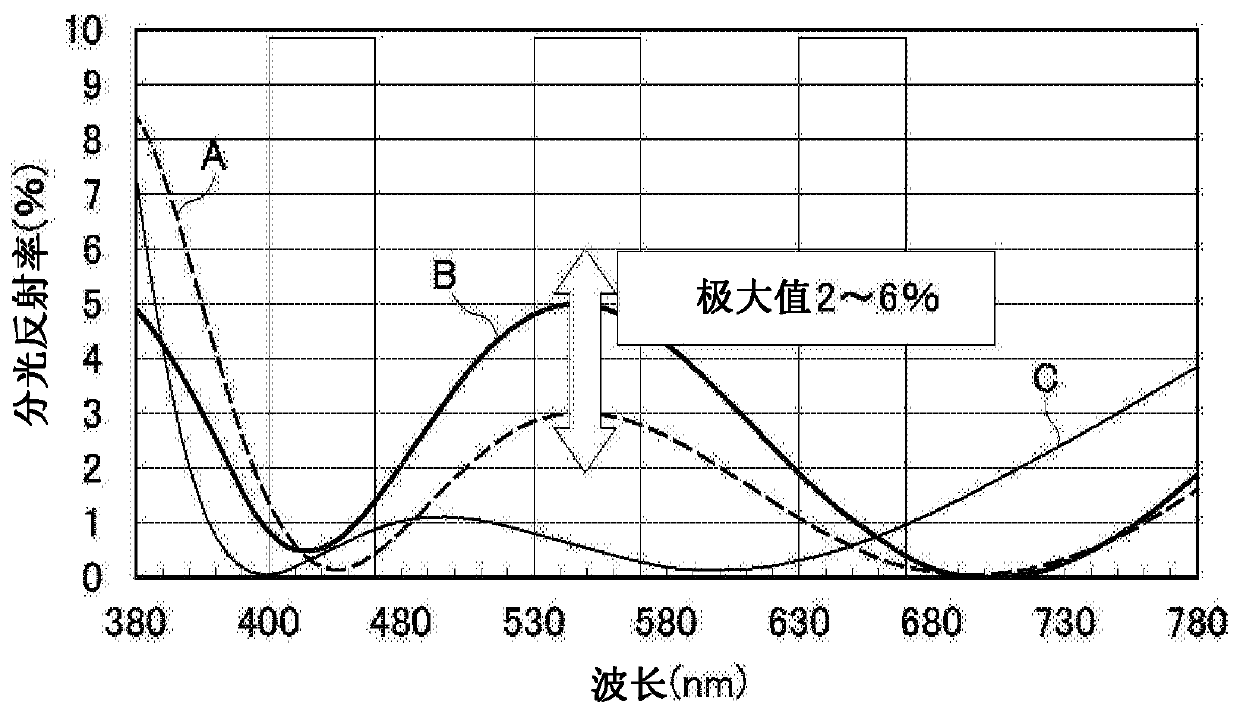

[0165] exist figure 1 On both sides of the urethane-based synthetic resin substrate shown as the plastic substrate 2 (the surface (front side: outer side) and back side (face side) of the spectacle lens 1), a primer with a refractive index of 1.67 is formed by heating and curing. layer and a silicon-based hard coat layer with a refractive index of 1.67, perform pretreatment to form a functional thin film 4 composed of an undercoat layer 5 and a hard coat layer 6, and then, as shown below, deposit The optical multilayer films 3a and 3b were formed to produce the spectacle lens 1 of Example 1.

[0166] Back: The urethane-based synthetic resin substrate (hereinafter referred to as the plastic substrate 2) is placed on the rotating dome provided in the vacuum tank, the temperature in the vacuum tank is heated to 70 degrees, and exhaust is performed until The pressure becomes 1.0×10 - 3 Up to Pa, after Ar ion beam cleaning was performed for 60 seconds under the conditions of ac...

Embodiment 2

[0176] After performing pretreatment on both surfaces of the plastic substrate 2 in the same manner as in Example 1, as shown below, the optical multilayer films 3a and 3b were formed by vacuum evaporation to produce the spectacle lens 1 of Example 2. .

[0177] Front side: Using the same device as in Example 1, under the same processing atmosphere, the first layer with an optical film thickness of 0.250λ is sequentially laminated on the front side of the pretreated plastic substrate 2 by vacuum evaporation method from the front side. SiO 2 (Refractive index 1.47), second layer ZrO with optical thickness 0.040λ 2 (Refractive index 2.00), 3rd layer SiO with optical film thickness 0.060λ 2 (Refractive index 1.47), 4th layer ZrO with optical thickness 0.550λ 2 (Refractive index 2.00), 5th layer SiO with optical film thickness 0.250λ 2 (refractive index 1.47), an optical multilayer film 3a was formed.

[0178] Backside: using the same device as in Example 1, under the same pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com