Impeller-type aerator

An aerator and impeller-type technology, which is applied in the field of impeller-type aerators, can solve problems such as easy-to-wet control devices, limited impeller rotation space, and increased motor load power, so as to reduce the risk of burnout and avoid phase loss Problems, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

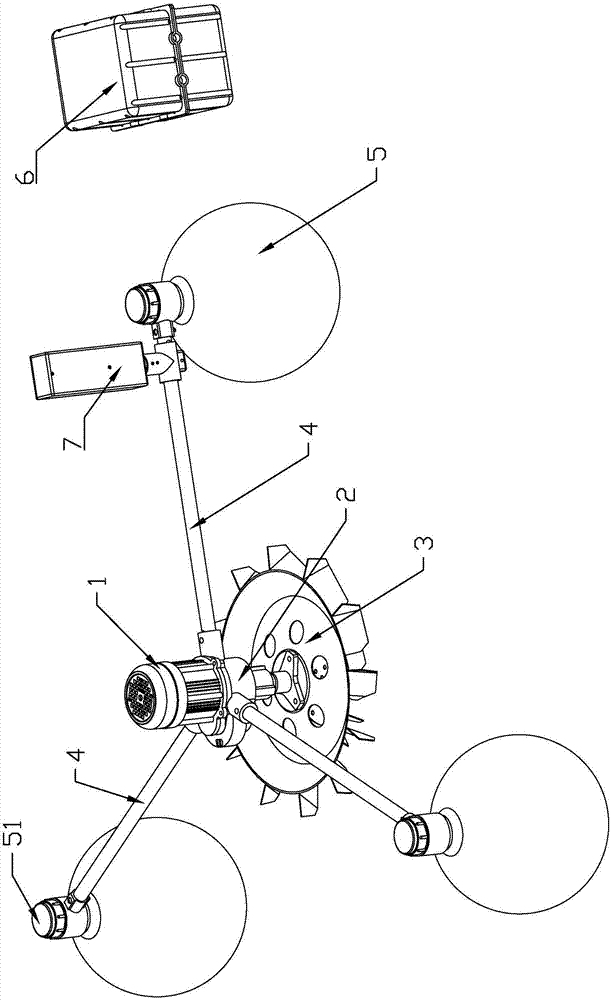

[0062] This embodiment relates to an impeller type aerator, such as Figure 1-8 As shown, it includes a frequency conversion controller, a motor 1, a reducer 2, and an impeller 3 connected in sequence. The reducer is connected to the floating body 5 of the whole machine through a strut 4. The frequency conversion controller converts alternating current into direct current and outputs it to the electric motor.

[0063] Place the floating body on the water, connect the frequency converter or other frequency conversion equipment with the motor and the controller, the controller sends the start action, and the frequency converter converts the single-phase AC power of the grid, such as 220V, into a DC power of the rated voltage of the motor, and outputs it to the motor, and the motor Drive the impeller to rotate, and the impeller is between the water body and the air, so that the whole aerator works to increase the oxygen of the water body.

[0064] In order to avoid water splashi...

Embodiment 2

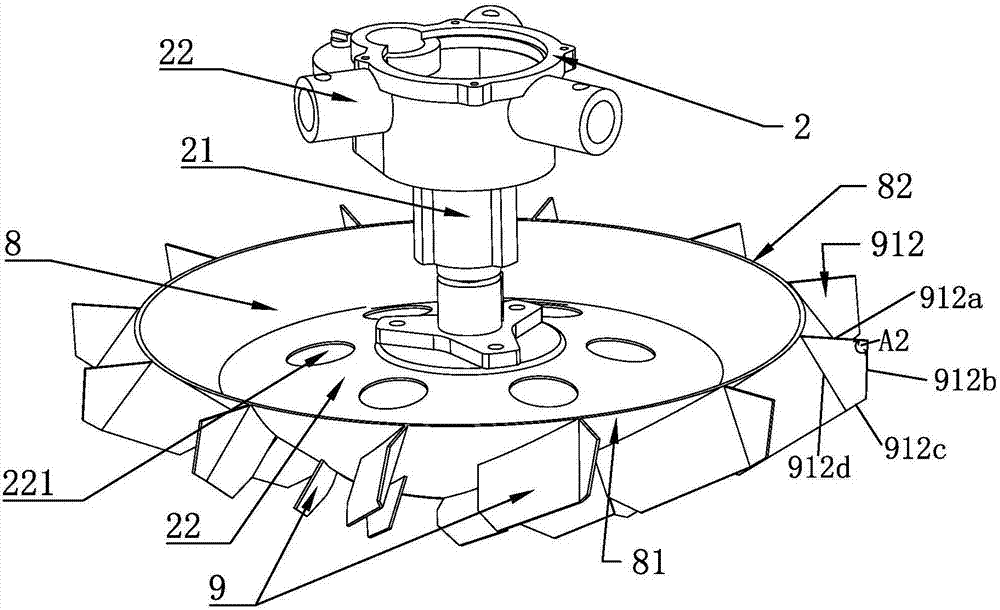

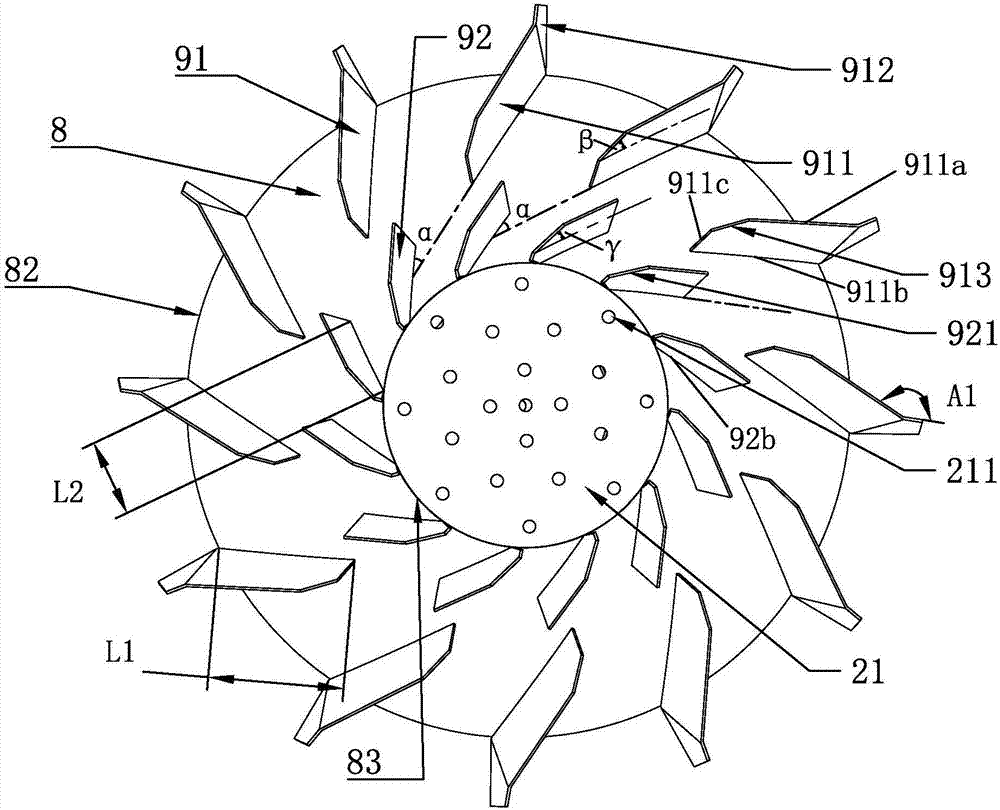

[0076] Different from Embodiment 1, the impeller 3 in this embodiment includes an impeller disc 8 and several blades 9, such as Figure 1-8 As shown, the plurality of blades are arranged on the surface of the impeller disk in two circles up and down in a radial shape. The directions of radial arrangement of the blades on the upper and lower circles are the same, image 3 Described in the radial arrangement in a clockwise direction.

[0077] The impeller disk 8 adopts a rounded platform structure formed by connecting fan ring plates end to end, and the blades 9 shown are arranged on the outer surface 81 of the impeller disk 8 .

[0078] The blade 9 includes an upper blade 91 and a lower blade 92 , the upper blade is arranged on the upper side of the impeller disk 8 , and the lower blade is arranged on the lower side of the impeller disk 8 . Wherein, the extension line of any one of the lower blades 92 is located between two adjacent upper blades 91, adopting this staggered ar...

Embodiment 3

[0084] Same as Embodiment 2, the included angle between the upper blade 91, the lower blade 92 and the impeller disc in this embodiment is 0-90 degrees. The optimal setting is that the angle between the upper blade and / or the lower blade and the outer surface of the impeller disk is 45 degrees or 60 degrees or is tangent. The area of the upper blade is greater than that of the lower blade, preferably the upper blade is greater than or equal to 1.5 times the area of the lower blade.

[0085] As a preferred setting, the angle of inclination of the upper blade or the lower blade is different.

[0086] As a preferred setting, the extension line of any one blade 9 does not intersect with the central axis of the impeller disk.

[0087] In this embodiment, the entire impeller is made of 304 stainless steel or other rust-proof and light-weight metals. The pH of the water body is unstable, and there are a lot of microorganisms in the water body. The use of 304 stainless steel avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com