Continuous tank reactor and continuous tank reaction system with n-butyllithium participating in production

A reaction device and reaction system technology, which is applied in chemical/physical/physical chemical fixed reactors, lithium organic compounds, etc., can solve problems such as poor reaction safety, improve reaction efficiency, reduce operational risks, and reduce one-time transfers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

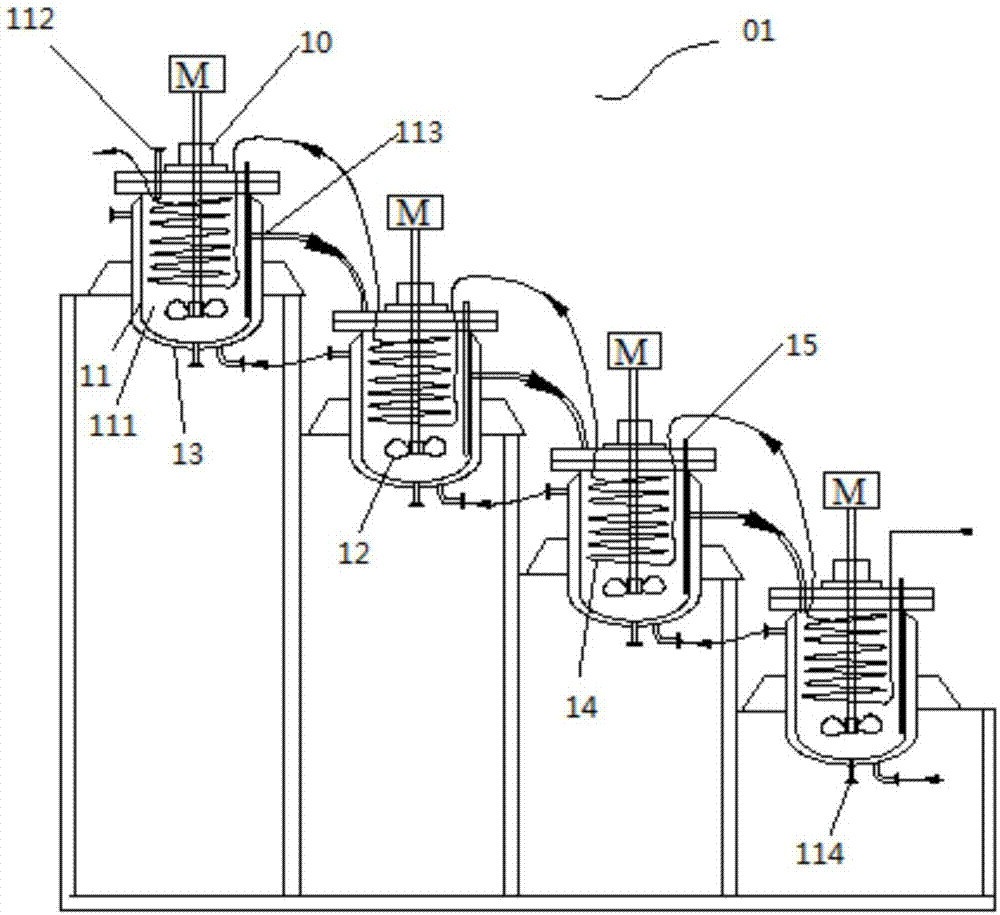

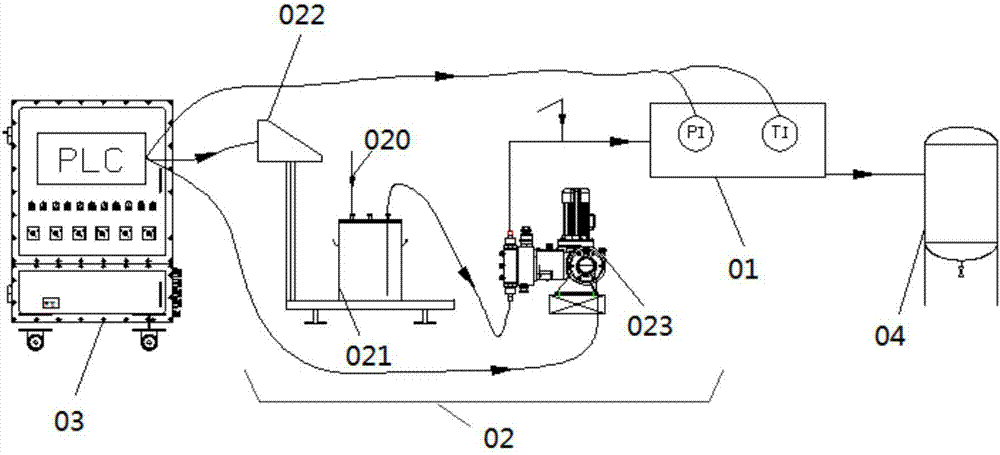

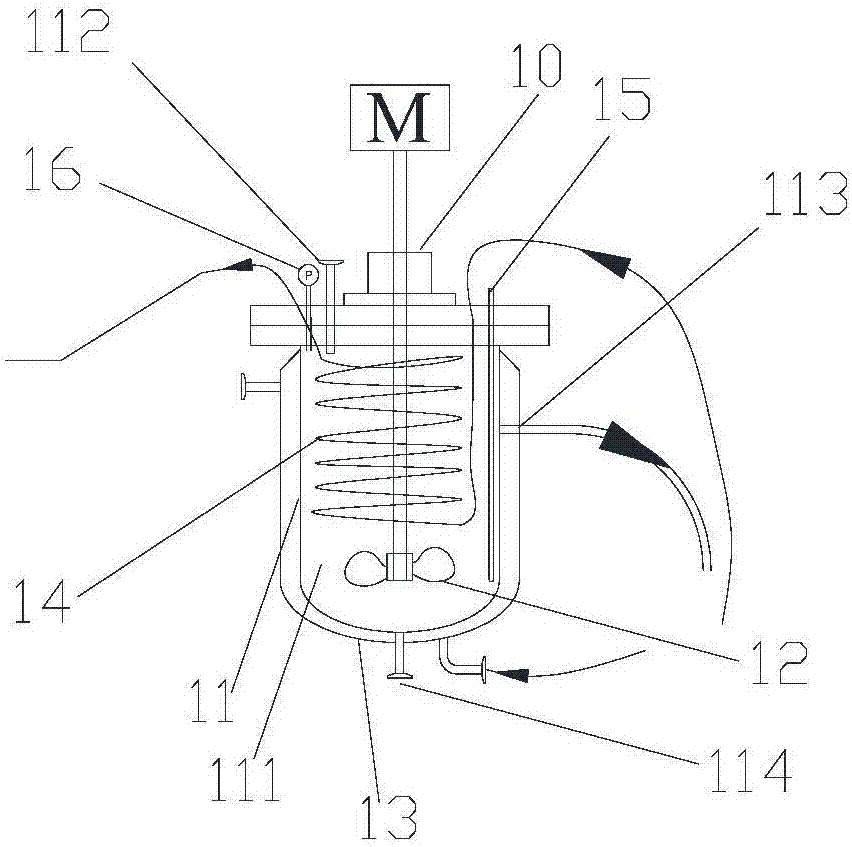

[0039] As mentioned in the background technology, most of the existing n-butyllithium reactions are produced in batches and single-pots, which often require one-time transfer or long-term dropwise addition of a large amount of n-butyllithium, resulting in high process risks. In order to reduce the risk of this similar reaction, in a typical implementation of the present application, a continuous tank reaction device 01 is provided, such as figure 1 and image 3 As shown, the continuous tank reaction device 01 includes N continuous reactors 10 arranged in series in sequence, each continuous reactor 10 includes a body 11, and the body 11 has a reaction chamber 111, a feed port 112, an overflow port 113 and an outlet. A fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com