Production method of pellet type aminophylline bulk drug

A production method, the technology of aminophylline, applied in the direction of raw material extrusion granulation, organic chemistry, chemical/physical/physical chemical fixed reactor, etc., can solve problems such as unsatisfactory product improvement, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments, but not as a limitation to the present invention.

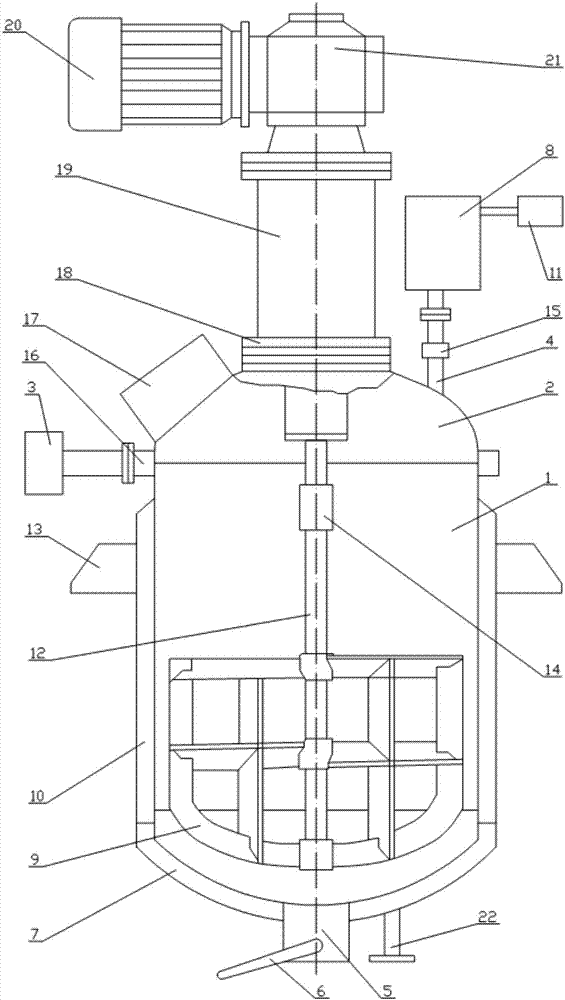

[0018] 1. Main production equipment

[0019] name

Specifications

The main material

amount)

Ethylenediamine evaporation tank

500L

304

1

Addition tank for the production of aminophylline granular raw material medicine

800L

304

1

Swing pellet machine

YK-160

Stainless steel

1

[0020] 2. The production method of aminophylline granular bulk drug

[0021] 2.1 Distillation and purification of ethylenediamine

[0022] Reduced pressure distillation: turn on the vacuum pump, check that the vacuum system is well sealed, and keep the vacuum degree of the evaporation and return system ≥ 0.06MPa through operation; turn on the condensing equipment, open the steam inlet valve of the external coil of the distillation equipment, and start to process the eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com