Circulation and decoloration device for epoxy type plasticizer production and processing

A plasticizer and epoxy technology, which is applied in the field of cyclic decolorization devices for the production and processing of epoxy plasticizers, can solve the problem of inability to fundamentally remove pigments, poor decolorization effect of epoxidized soybean oil, and inability to improve decolorization effect, etc. problems, to achieve the effect of convenient cleaning or replacement, increased decolorization efficiency, and improved mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

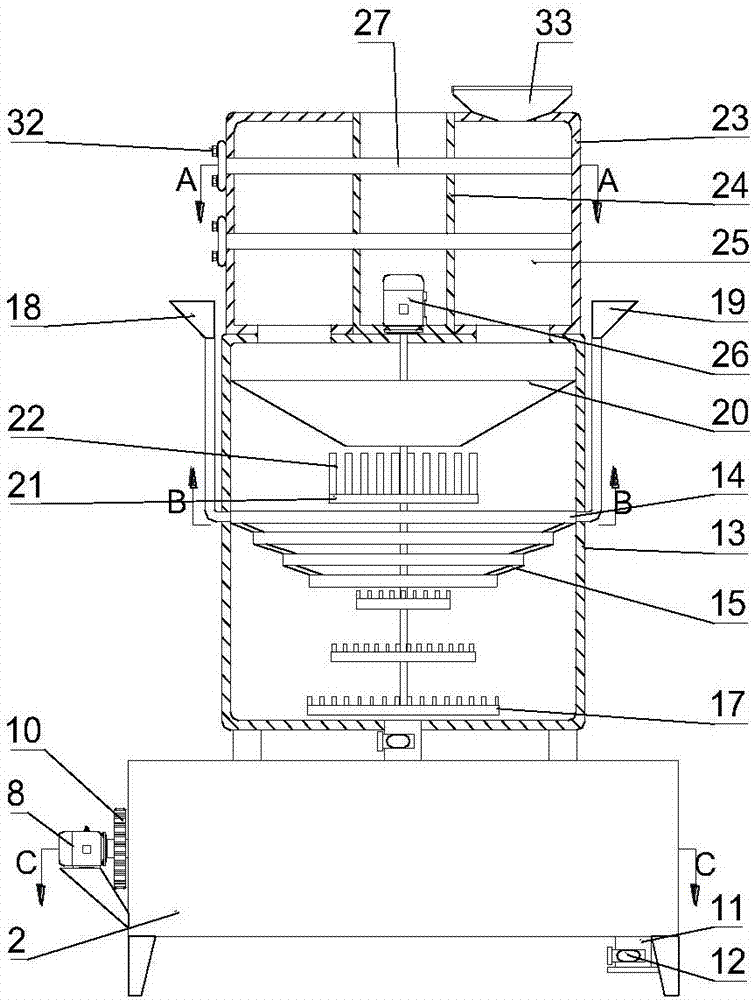

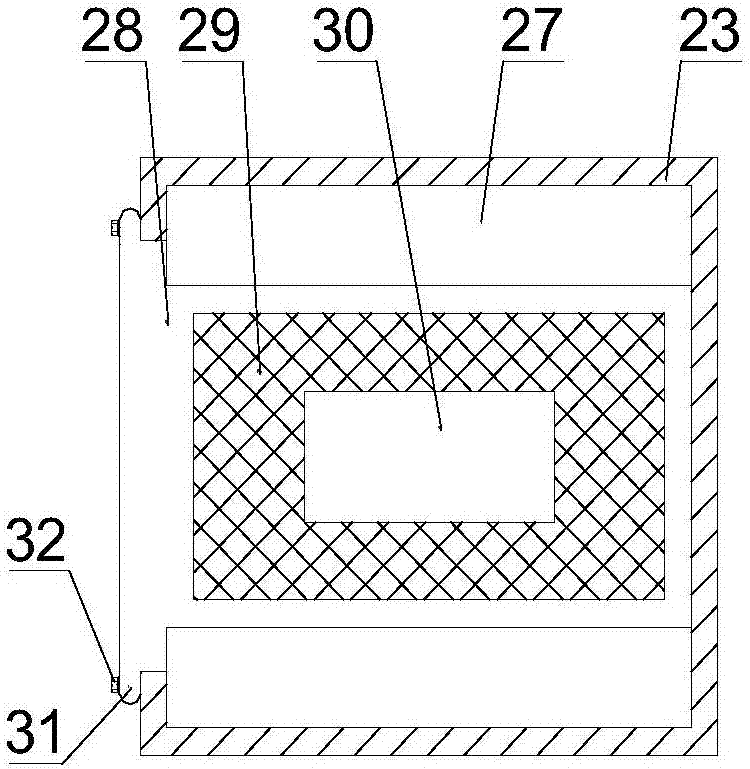

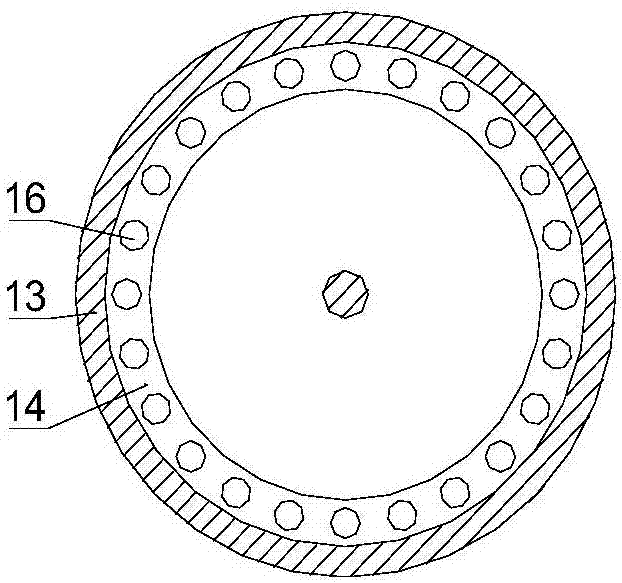

[0019] see Figure 1-4 , a circulation decolorization device for the production and processing of epoxy plasticizers, comprising a tank body 13, an annular dripping pipe 14, an alkali solution injection funnel 18, a hydrogen peroxide injection funnel 19, a first circulation cylinder 1, and a second circulation cylinder 2. The first helical blade 5, the second helical blade 6, the outer fixed frame 23, the inner fixed frame 24 and the driving device, the first circulation cylinder 1 and the second circulation cylinder 2 are arranged in parallel front and back, and the first circulation The cylinder body 1 and the second circulation cylinder body 2 are fixedly connected through two return pipes 7, and the two return pipes 7 are located on the left and right sides of the first circulation cylinder body 1 and the second circulation cylinder body 2 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com