Separation and recovery vehicle for tableware and food residue

A technology for separation and recovery of residues, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. Pollution, taking into account the effect of environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

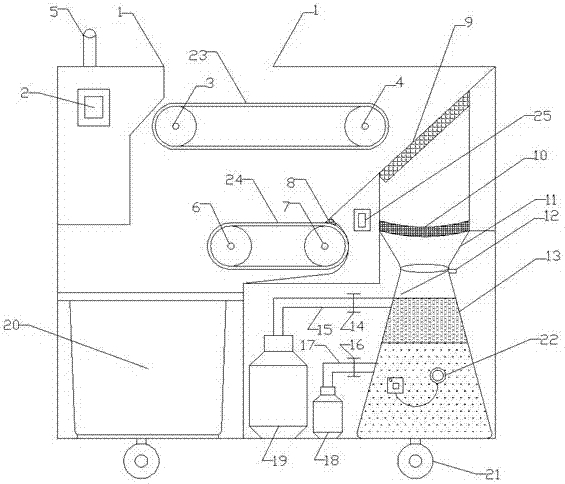

[0014] Embodiment 1: as figure 1 As shown, a tableware and catering residue separation and recovery vehicle, including tableware placement port 1, conveyor belt switch I2, roller I3, roller II4, recycling handle 5, roller III6, roller IV7, rubber spacer 8, primary screen 9 , secondary screen 10, inverted funnel 11, inclined plate 12, trapezoidal oil-water resting barrel 13, control valve Ⅰ 14, conduit Ⅰ 15, control valve Ⅱ 16, conduit Ⅱ 17, waste water recovery barrel 18, waste oil recovery barrel 19, tableware recovery Bucket 20, wheel 21, non-contact liquid level sensor 22, conveyor belt I23, conveyor belt II24, conveyor belt switch II25;

[0015] Including tableware placement port 1, conveyor belt switch Ⅰ2, roller Ⅰ3, roller Ⅱ4, roller Ⅲ6, roller Ⅳ7, rubber spacer 8, primary screen 9, secondary screen 10, inverted funnel 11, inclined plate 12, trapezoidal oil-water static Set barrel 13, control valve Ⅰ14, conduit Ⅰ15, control valve Ⅱ16, conduit Ⅱ17, waste water recovery b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com