Steel pipe seam joining and welding integrated machine

An all-in-one machine and welding mechanism technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult to guarantee the structural strength of steel pipes, uneven width of steel pipe welds, and difficult to guarantee welding accuracy, etc. The effect of keeping the gap width stable, the welding seam width uniform, and reducing the difficulty of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

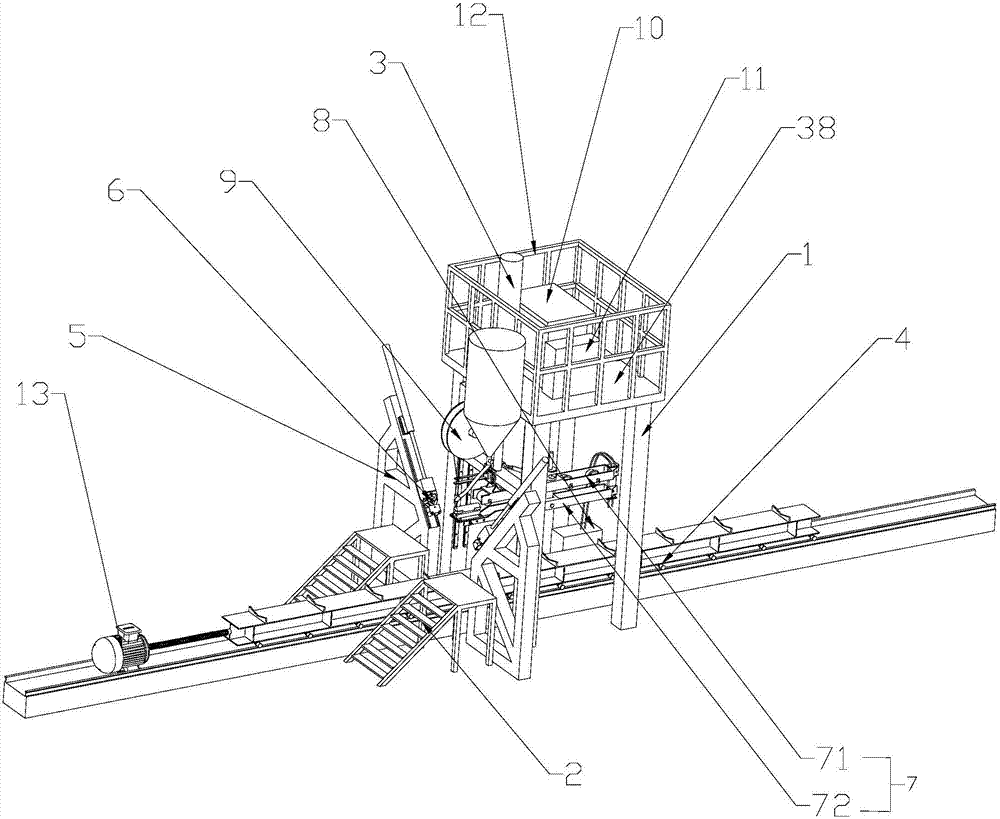

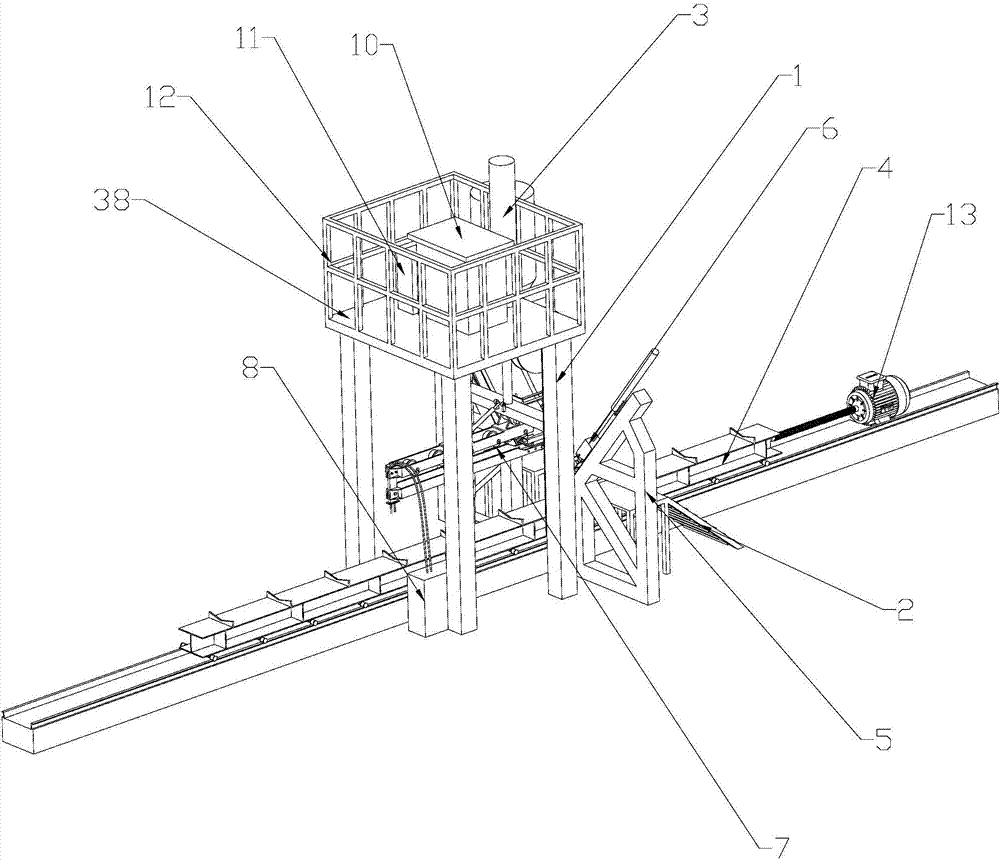

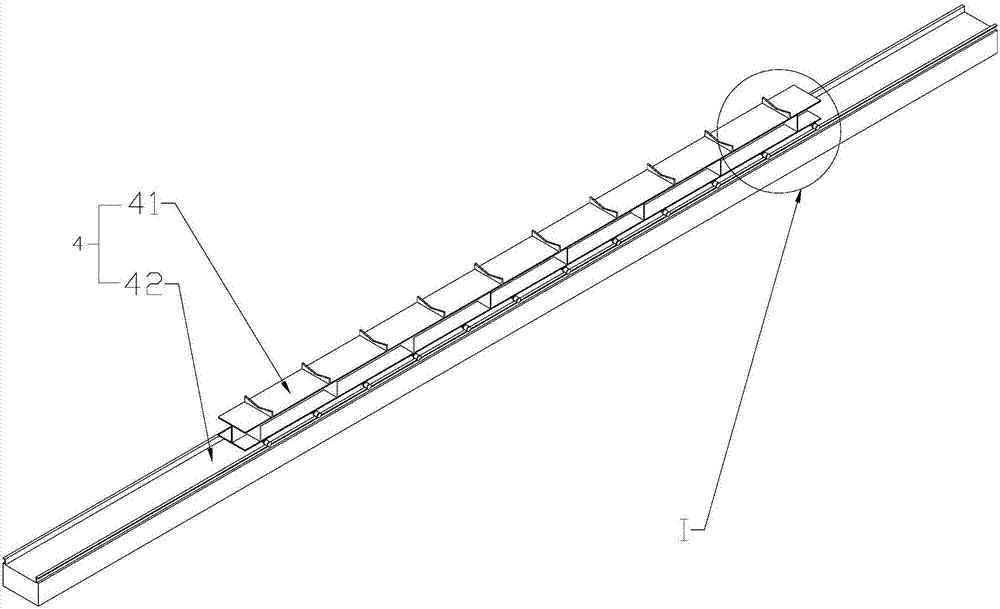

[0045] refer to Figure 1 to Figure 14 The embodiments of the present invention will be further described.

[0046] Such as Figure 1 to Figure 2 As shown, a steel pipe seam welding machine includes a main frame 1, the main frame 1 is a cuboid structure, the main frame 1 is welded by several square steels, and a steel pipe for transporting steel pipes to be welded is installed under the main frame 1. The conveying device 4, the main frame 1 is the rear side and the front side in sequence along the steel pipe conveying direction, and the steel pipe conveying direction is as follows figure 1 In the direction shown by the arrow, the front side of the main frame 1 is connected with the welding mechanism 9 and the main oil cylinder 3, and there are two side frames 5 placed on the front side of the main frame 1. The side frames 5 are respectively located on the left and right sides of the steel pipe. On the side frame 5 The pressure roller assembly 6 used to fix the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com